ENVIRO-TEC

13

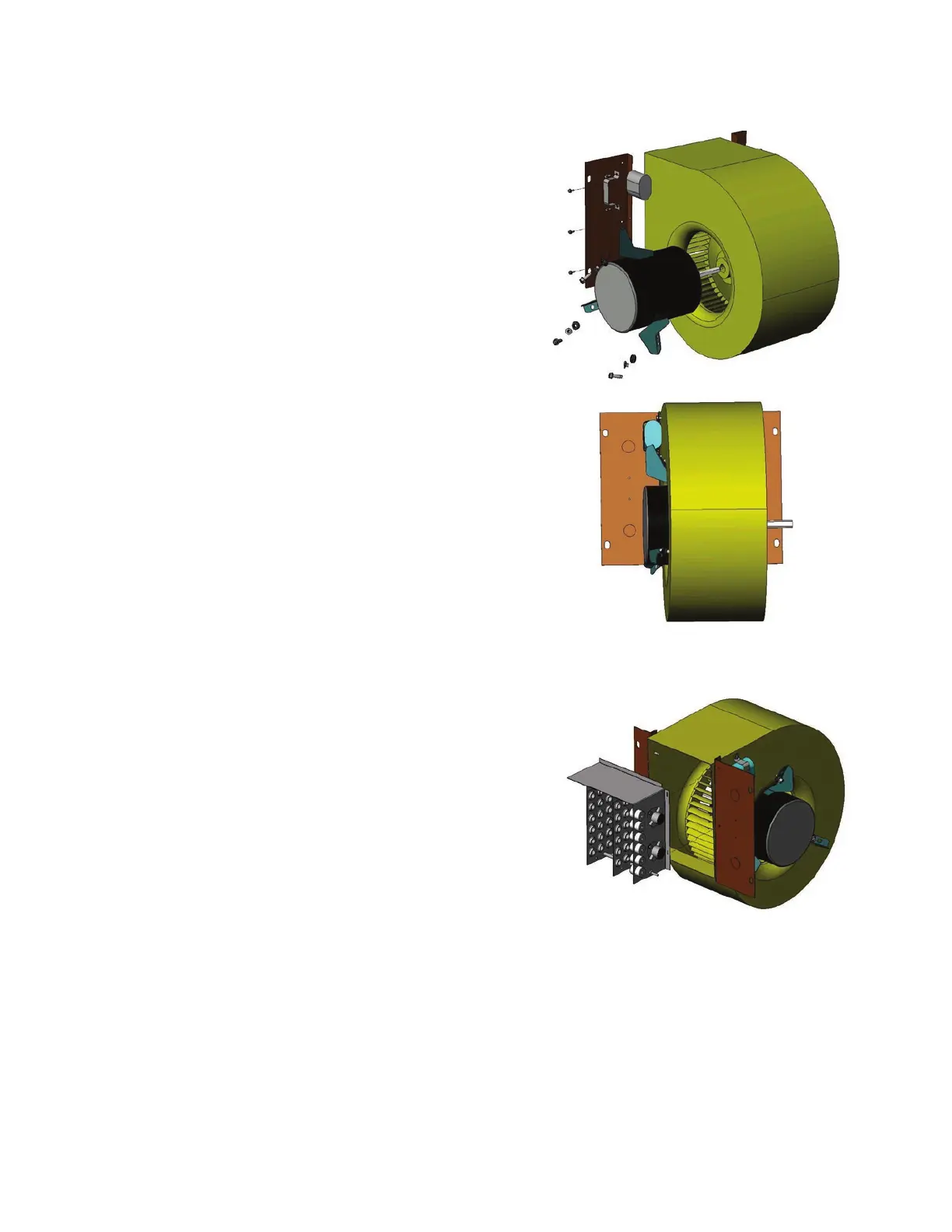

FAN ASSEMBLY

Each fan assembly is easily removed from the unit at

four ¼” weld studs in the fan deck. In most applications

the fan assembly can be removed without disconnecting

the ductwork for service access to motors and blowers

at, or away from the unit.

Should the assembly require more extensive service,

the motor/blower assembly may be removed from the

unit to facilitate such operations as motor or blower

wheel/housing replacement, etc. Dirt and dust should

not be allowed to accumulate on the blower wheel or

housing. This can result in an unbalanced blower wheel

condition that can damage a blower wheel or motor.

The wheel and housing may be cleaned periodically

using a vacuum cleaner and a brush taking care not to

dislodge the factory balancing weights on the blower

wheel blades.

To remove the motor from the fan, disconnect the motor

wire leads, loosen the set screw on the motor shaft and

remove the (3) cap screws that attached the motor to the

blower housing. To reassemble, insert the motor into

the blower wheel, (motor slots to be facing up) center

the blower wheel within the blower housing and tighten

the set screw. Reinstall the (3) cap screws and tighten

to 40 in/lbs. Place the entire fan assembly back up over

the weld studs, install the washers and tighten the 1/4-20

nylok nuts to 65 in/lbs.

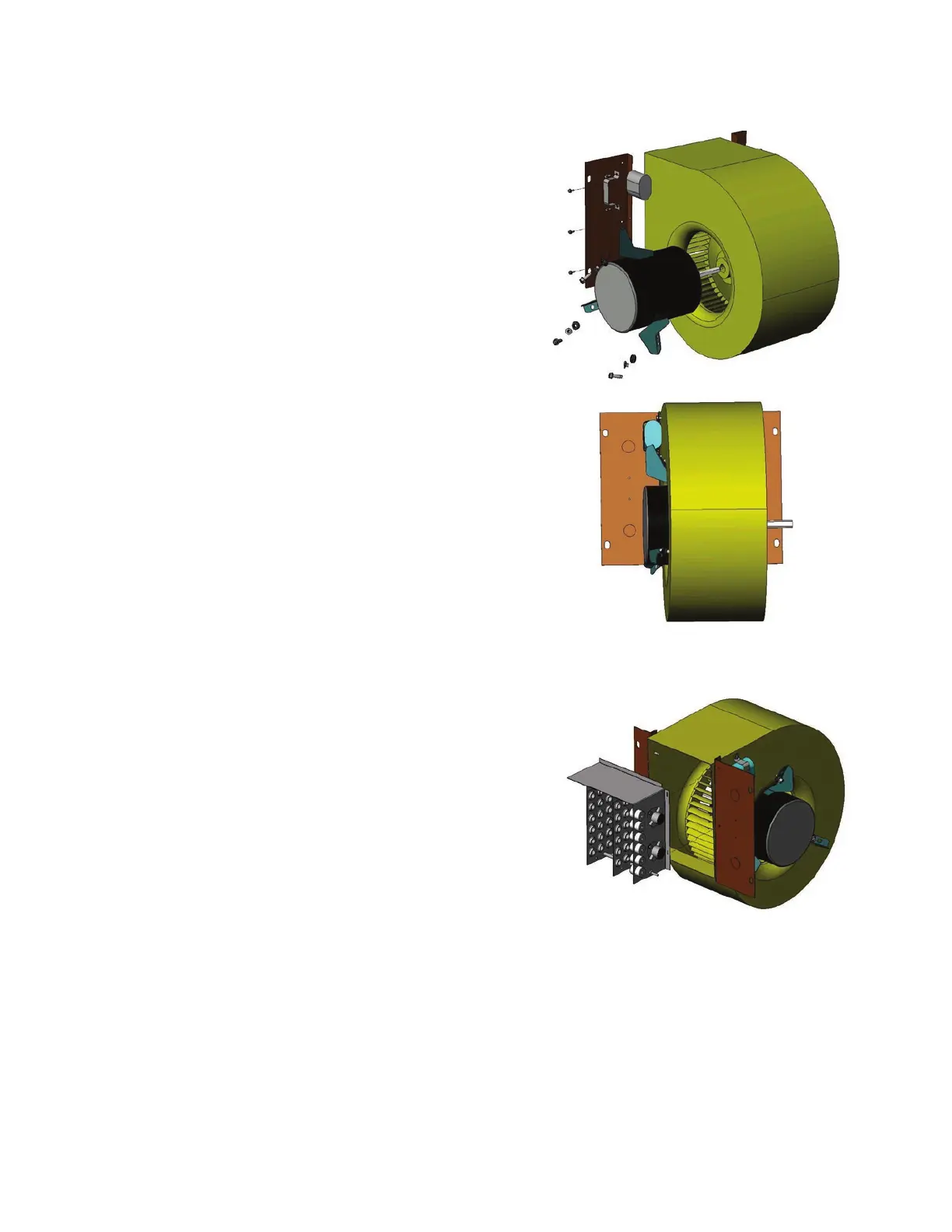

COIL

Coils may be cleaned in place by removing the motor/

blower assemblies and brushing the entering air face

between ns with a soft brush parallel to ns.

Do not brush perpendicular to n orientation as damage

may occur. Brushing should be followed by cleaning

with a vacuum cleaner. If a compressed air source is

available, the coil may also be cleaned by blowing

air through the coil ns from the entering air face.

Vacuuming should again follow this. Units provided

with the proper type of air lters, replaced regularly,

may require periodic coil cleaning.

Fan Assembly Removal

Electric Heater Removal

Loading...

Loading...