ENVIRO-TEC

7

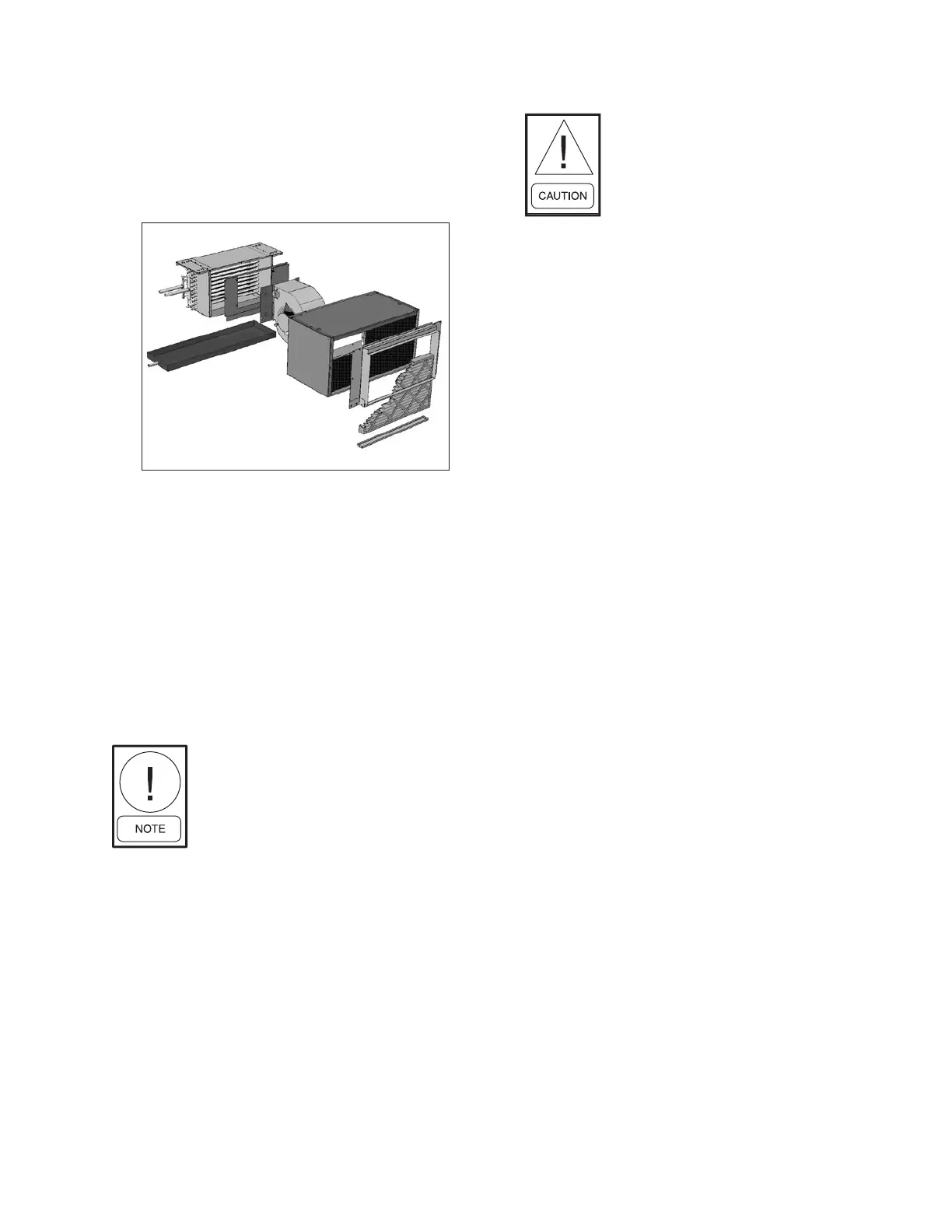

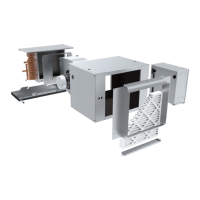

PLENUM BOX REMOVAL

In most cases this unit is fully serviceable without the

need for removal of the plenum box. However should

the need arise, the plenum box is easily removable by

removing the screws attaching the plenum box to the

sides, top and rear of the coil casing.

COIL HANDING

This unit features a eld reversible coil assembly should

the need arise upon installation to change the handing of

the coil. To change the coil handing, remove the plenum

box (if applicable) from the coil by removing all screws

to the coil casing. Next, remove the fan(s), fan deck,

and top and bottom casings from the coil. Rotate the

coil. Replace the bottom coil casing in the top coil casing

position and the top coil casing in the bottom coil casing

position and reattach the fan deck, fan(s) and plenum

box (if applicable) in the original locations.

The leaving air side of the n pack

will remain the same after changing

the coil handing.

COILS

All fan coils are available in 2 or 4 pipe congurations.

Heating and cooling coils are eld reversible for right

or left side connections. On units with water coils, the

maximum water pressure applied to the unit should

never exceed 300 PSIG at 200°F. On units with steam

heating coils, the maximum steam pressure applied

to the unit should never exceed 15 PSIG. The drain

piping and steam trap should be sized and routed to

allow for proper condensate ow. (Minimum ambient

temperature 35°F. Coils may freeze.)

PIPING CONNECTIONS

Toxic residues and loose particles

resulting from manufacturing and

eld piping techniques such as joint

compounds, soldering ux, and metal

shavings may be present in the unit

and the piping system. Special con-

sideration must be given to system

cleanliness when connecting to solar,

domestic or potable water systems.

Submittals and Product Catalogs detailing unit operation,

controls, and connections should be thoroughly

reviewed BEFORE beginning the connection of the

various cooling and/or heating mediums to the unit.

All accessory valve packages should be installed as

required, and all valves should be checked for proper

operation.

If coil and valve package connections are to be made

with “sweat” or solder joint, care should be taken to

assure that no components in the valve package are

subjected to a high temperature which may damage seals

or other materials. Many two-position electric control

valves, depending on valve operation, are provided with

a manual-opening lever. This lever should be placed

in the “open” position during all soldering or brazing

operations. Valve bodies should be wrapped with a wet

rag to help dissipate heat encountered during brazing.

Use a brazing alloy to make connections such as BCup-

2. Soft solder is not recommended.

If the valve package connection at the coil is made with

a union, the coil side of the union must be prevented

from twisting (“backed up”) during tightening to prevent

damage to the coil tubing. Over-tightening must be

avoided to prevent distorting the union seal surface

and destroying the union. In the case of eld installed

valves and piping, the chilled water valve cluster (or

expansion valve on DX units) should be installed in

such a way that any dripping or sweating is contained

in the auxiliary drain pan or other device. Valves and

TXV’s should be secured or supported to avoid damage

to coil headers or distributor tubes.

Loading...

Loading...