ENVIRO-TEC

14

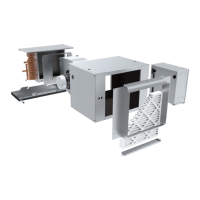

ELECTRIC RESISTANCE HEATER ASSEMBLY

ELECTRICAL SHOCK HAZARDS. ALL

POWER MUST BE DISCONNECTED

PRIOR TO INSTALLATION AND SERV-

ING THIS EQUIPMENT. MORE THAN

ONE SOURCE OF POWER MAY BE

PRESENT. DISCONNECT ALL POWER

SOURCES TO AVOID ELECTROCUTION OR SHOCK

INJURIES.

Electric resistance heaters typically require no normal

periodic maintenance when unit air lters are changed

properly. Other conditions and equipment may affect the

operation and service life in the system. The two most

important operating conditions for an electric heater are

proper airow and proper supply voltage. High supply

voltage and/or poorly distributed or insufcient airow

over the element will result in element overheating.

This condition may result in the heater cycling on the

high limit thermal cutout. The open wire type heaters

provided have an automatic reset switch with a back-up

high limit thermal switch. Automatic reset switches are

as the name implies; they reset automatically after the

heater has cooled down. High limit thermal switches

must be replaced once the circuit has been broken.

The high limit thermal cutout device is a safety device

only and is not intended for continuous operation. With

proper unit application and during normal operation,

the high limit thermal cutout will not operate. This

device only operates when some problem exists and

ANY condition that causes high limit cutout MUST be

corrected immediately. High supply voltage also causes

excessive amperage draw and may result in tripping

of the circuit breaker or blowing of the fuses on the

incoming power supply.

ELECTRICAL WIRING & CONTROLS

The electrical operation of each unit is determined by

the components and wiring of the unit and may vary

from unit to unit. Consult the wiring diagram for the

actual type and number of controls provided on each

unit. The integrity of all electrical connections should be

veried at least twice during the rst year of operation.

Afterwards, all controls should be inspected regularly

for proper operation. Some components may experience

erratic operation or failure due to age. Wall thermostats

may also become clogged with dust and lint and should

be periodically inspected and cleaned to provide reliable

operation.

When replacing any components such as fuses,

contactors, or relays, use only the exact type, size, and

voltage component as furnished from the factory. Any

deviation without factory authorization could result

in personnel injury or damage to the unit and will

void all factory warranties. All repair work should be

done in such a manner as to maintain the equipment in

compliance with governing codes and ordinances or

testing agency listings.

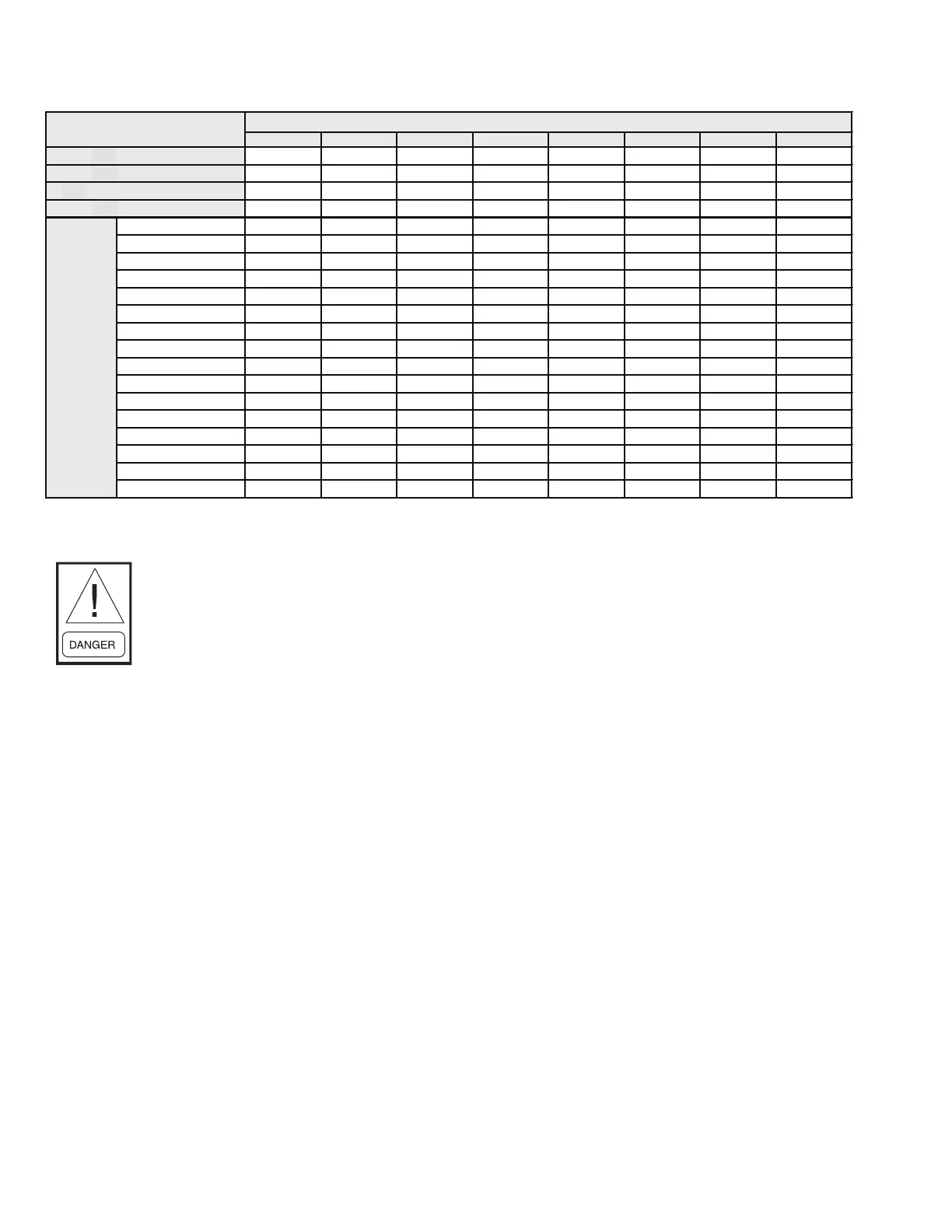

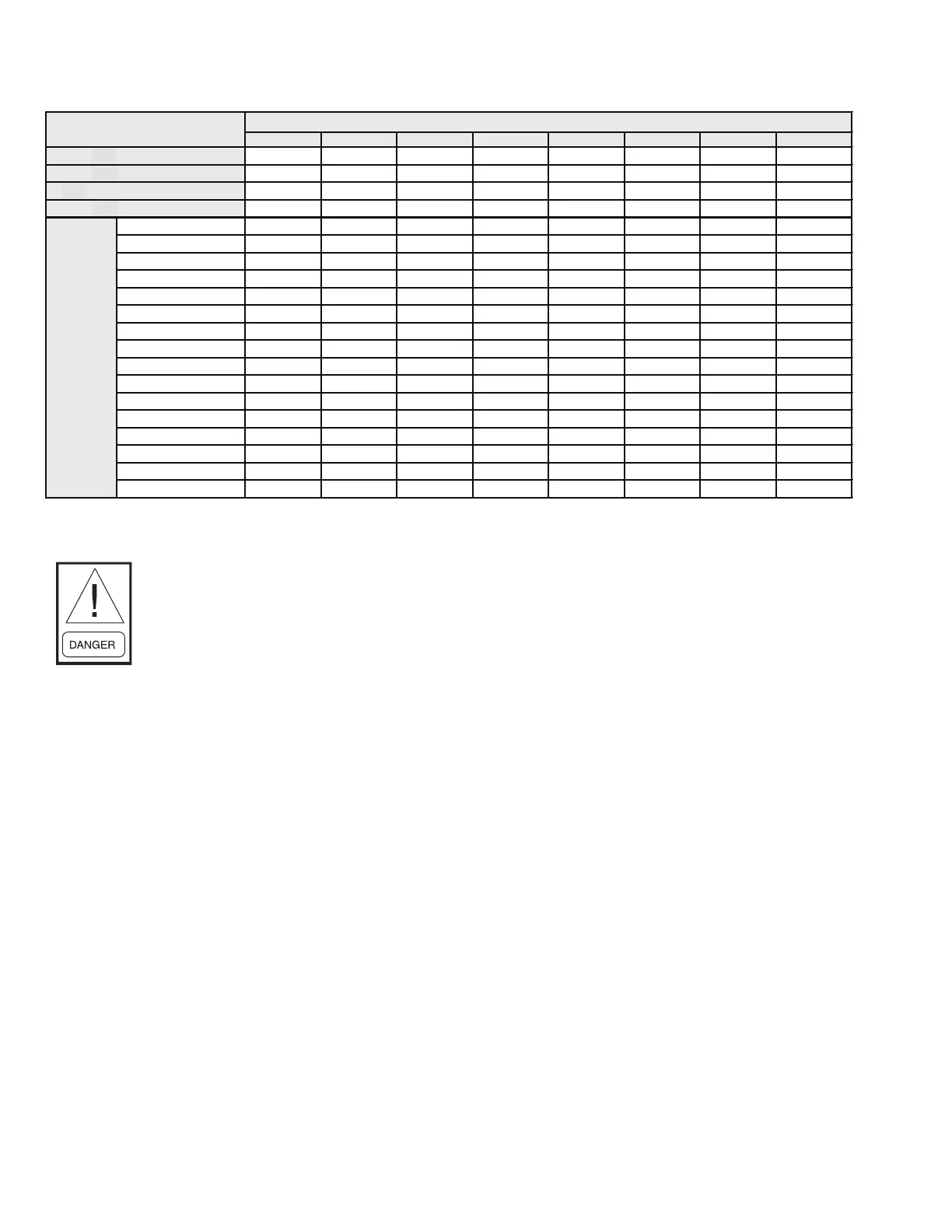

Unit Weight Data

NOTE: Unit weight data is in pounds [kilograms].

68 [31] 73 [33] 77 [35] 114 [52] 119 [54] 124 [56] 128 [58] 132 [60]

87 [40] 95 [43] 101 [46] 141 [64] 150 [68] 157 [71] 164 [75] 170 [77]

119 [54] 132 [60] 144 [65] 189 [86] 204 [93] 217 [99] 229 [104]246 [112]

137 [62] 146 [66] 158 [72] 202 [92] 219 [99] 228 [103]240 [109]250 [113]

1 ROW - DRY

5 [2]6 [3]7 [3]8 [4]10 [5]10 [5]11 [5]12 [5]

1 ROW - WET

7 [3]9 [4]10 [5]11 [5]14 [6]14 [6]16 [7]17 [8]

2 ROW - DRY

11 [5]13 [6]14 [6]16 [7]20 [9]20 [9]22 [10] 24 [11]

2 ROW - WET

14 [6]18 [8]20 [9]23 [10] 27 [12] 28 [13] 32 [15] 35 [16]

3 ROW - DRY

16 [7]19 [9]21 [10] 24 [11] 30 [13] 30 [14] 33 [15] 36 [16]

3 ROW - WET

21 [10] 27 [12] 30 [14] 34 [15] 41 [19] 42 [19] 48 [22] 52 [24]

4 ROW - DRY

21 [10] 25 [12] 29 [13] 33 [15] 40 [18] 40 [18] 44 [20] 48 [22]

4 ROW - WET

27 [12] 35 [16] 41 [19] 46 [21] 54 [25] 56 [25] 64 [29] 69 [31]

5 ROW - DRY

26 [12] 30 [14] 34 [16] 38 [17] 42 [19] 46 [21] 50 [23] 54 [25]

5 ROW - WET

33 [15] 39 [18] 45 [21] 51 [23] 57 [26] 63 [29] 70 [32] 77 [35]

6 ROW - DRY

32 [15] 38 [17] 43 [19] 49 [22] 59 [27] 61 [28] 67 [30] 71 [32]

6 ROW - WET

42 [19] 53 [24] 61 [28] 69 [31] 80 [36] 85 [39] 97 [44] 103 [47]

7 ROW - DRY

38 [17] 42 [19] 48 [22] 54 [25] 60 [28] 66 [30] 72 [33] 78 [35]

7 ROW - WET

49 [23] 56 [26] 63 [29] 70 [32] 77 [35] 84 [38] 91 [42] 98 [45]

8 ROW - DRY

43 [20] 49 [22] 55 [25] 61 [28] 67 [30] 73 [33] 79 [36] 85 [39]

8 ROW - WET

55 [26] 63 [29] 71 [32] 79 [36] 87 [40] 95 [43] 103 [47] 111 [50]

TOTAL

COIL

ROWS

COMPONENT

HPF

HPP

HPP

HPE

Loading...

Loading...