ENVIRO-TEC

21

CHECKING ECM CABLES

Remove power from the unit. Unplug signal cable at

motor, but leave quick connects attached to ETPWM

board and fan relay or quick connect terminal block (see

Figure 3). Use ohmmeter to check continuity. Repeat

process for three wire power cable if signal cable does

not appear to be defective (see Figure 3).

Only very light force is required when

inserting meter probe into plug. Ex-

cess force will damage contacts.

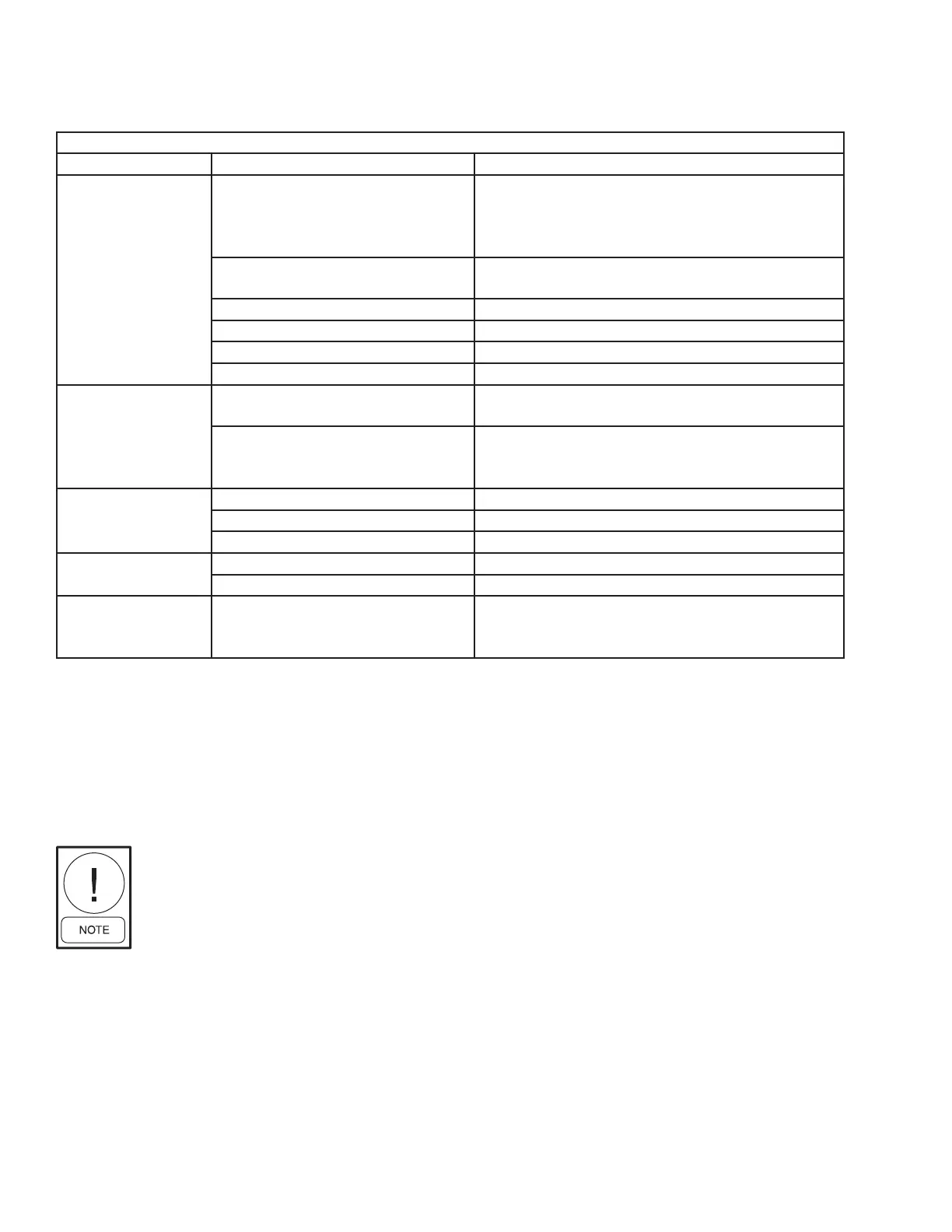

ECM SPECIFIC TROUBLESHOOTING GUIDELINES

PROBLEM POSSIBLE CAUSE CORRECTIVE ACTION

Motor Fails to Start

CFM Adjustment voltage above 10.0 VDC

or below 5.0 VDC. For units shipped prior to

April 2011, do not set voltage lower than 5.1

VDC or higher than 9.9 VDC.

Properly adjust CFM voltage.

ECM cables improperly seated at motor

Unplug cables from motor and re-install, making sure plugs on

cables are fully seated in motor receptacles.

ECM cables open or intermittent Replace cable(s). See section on checking cables below.

Mechanical failure Check motor and conrm it rotates freely.

Electrical failure Replace motor.

Fan Relay Contacts Oxidized/Suldized Replace fan relay.

Motor Surges

Fan CFM adjustment voltage outside range

of Fan Calibration Curve

Adjust voltage to value within range of Fan Calibration Curve.

ESP (external static pressure) too high

Verify no discharge obstructions and coil ns are free of debris.

Verify plenum opening is unobstructed. Verify lter (if supplied) is

not dirty and does not obstruct ow of plenum air.

Excessive Motor Noise

Motor mounting bolts loose Tighten motor mounting bolts.

Fan wheel rubbing on fan housing Align wheel in housing.

Loose fan wheel Align and tighten.

Poor Performance

Lack of required external static pressure Add required external static pressure.

Wrong Program Contact Factory.

Motor Runs in Reverse,

Doesn’t Respond to

Speed Adjustment

Motor Failure Replace.

Troubleshooting Guide for ECM Variable Speed Motor

Loading...

Loading...