ENVIRO-TEC

6

All water coils must be protected from

freezing after initial lling with water.

Even if the system is drained, unit coils

may still hold enough water to cause

damage when exposed to temperatures

below freezing.

Refrigerant systems should be tested with dry nitrogen

rather than air to prevent the introduction of moisture

into the system. In the event that leaking or defective

components are discovered, the Sales Representative

must be notied BEFORE any repairs are attempted.

All leaks should be repaired before proceeding with

the installation.

After system integrity has been established the piping

should be insulated in accordance with the project

specications. ALL chilled water piping and valves or

refrigerant suction piping not located over drain pans

must be insulated to prevent damage from sweating.

This includes factory and eld piping inside the unit

cabinet.

The drain should always be connected and piped to an

acceptable disposal point. For proper moisture carry-

off, the drain piping should be sloped away from the

unit at least 1/8” per foot. A drain trap may be required

by local codes and it is strongly recommended for odor

containment.

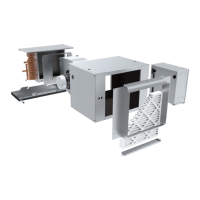

RETURN AIR LOCATION

This unit is equipped with a eld reversible rear or

bottom ducted air return for plenum style units.

To change the return air location, remove the reversible

plenum box panel and the lter rack. Rotate both the

reversible panel and lter rack 180 degrees. Replace

the reversible panel in the old lter rack position and

fasten using the supplied screws. Fasten the lter rack to

the location where the reversible panel was and replace

the lter(s) as described above.

FAN REMOVAL

This fan assembly is easily removable by unscrewing

the (4) ¼-20 nuts from the fan deck and sliding the

fan assembly off of the weld studs. Disconnect motor

wiring. Reassemble fans and torque nuts to 30 in/lbs.

PLENUM BOX SERVICE PANEL

The service panel on the plenum box is easily removable

by removing the screws located on the sides and bottom

of the service panel.

1 INCH PLUS CASING

STATIC PRESSURE

H

X

“X” MUST BE AT

LEAST 1 INCH

Condensate Trap

Trap detail for positive cabinet

static pressure

Bottom Return

Rear Return

Loading...

Loading...