ENVIRO-TEC

16

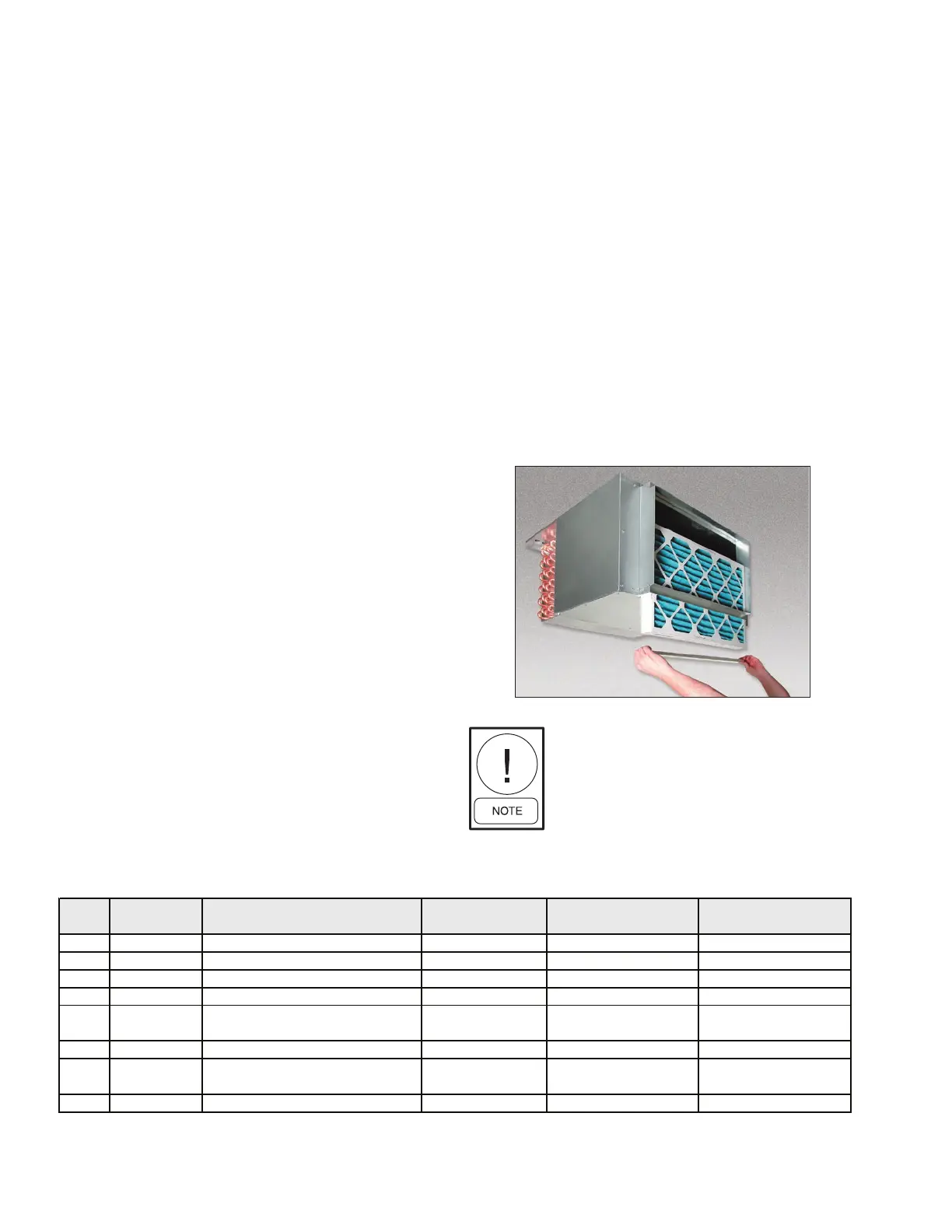

Face Area, Free Area and Filter Sizes

NOTES:

1. Face and free areas are in square feet [square meters].

2. Filter sizes are in inches [millimeters].

COIL FACE 1" THROWAWAY1" PLEATED2" PLEATED

AREA FACE AREA GROSS MEDIA AREA GROSS MEDIA AREA

06 1.56 [0.15]

(1) 16 x 16

[406 x 406] 1.62 [0.15] 4.0 [0.37] 5.4 [0.50]

08 2.08 [0.19]

(1) 16 x 20

[406 x 508] 2.04 [0.19] 4.8 [0.45] 6.8 [0.63]

10 2.50 [0.23]

(1) 16 x 25

[406 x 381] 2.57 [0.24] 6.0 [0.56] 8.5 [0.79]

12 3.02 [0.28]

(2) 16 x 16

[406 x 406] 3.23 [0.30] 8.0 [0.74] 10.4 [0.97]

14 3.54 [0.33]

(1) 16 x 16 & (1) 16 x 20

(1)

[406 x 406] & (1) [406 x 508]

3.65 [0.34] 8.8 [0.82] 12.2 [1.13]

16 4.06 [0.38] (2) 16 x 20 [406 x 508] 4.08 [0.38] 9.6 [0.89] 13.4 [1.24]

18 4.58 [0.43]

(1) 16 x 20 & (1) 16 x 25

(1) [406 x 508] & (1) [406 x 635]

4.61 [0.43] 10.8 [1.00] 14.3 [1.33]

20 5.00 [0.46]

(2) 16 x 25

[406 x 635] 5.14 [0.48] 12.0 [1.11] 17.0 [1.58]

NOMINAL FILTER SIZES

SIZE

VALVES & PIPING

No formal maintenance is required on the valve package

components most commonly used with fan coil units

other than a visual inspection for possible leaks in the

course of other normal periodic maintenance. In the

event that a valve should need replacement, the same

precautions taken during the initial installation to protect

the valve package from excessive heat should also be

used during replacement. In some cases, the valve

actuator may fail and usually can be replaced without

removing valve body from piping.

DRAIN

The drain should be checked before initial start-up and

at the beginning of each cooling season to assure that

the lines are clear. If it is clogged, steps should be taken

to clear the debris so that condensate will ow easily.

Periodic checks of the drain should be made during the

cooling season to maintain a free owing condensate.

Should the growth of algae and/or bacteria be a

concern, consult an air conditioning and refrigeration

supply organization familiar with local conditions for

chemicals available to control these agents. If cleaners

are used, they should be compatible with the materials

of construction for the coil and drain pan.

FILTERS

This unit is equipped with a standard 1” throwaway

lter most commonly used on fan coil units should be

replaced on a regular basis. The time interval between

each replacement should be established based on

regular inspection of the lter and should be recorded

in the log for each unit. At a minimum, lters should

be inspected monthly and replaced if needed. Refer to

the Filters chart for recommended lter size for each

product type and size. If the replacement lters are not

purchased from the factory, the lters used should be

the same type, size and MERV rating as that furnished

from or recommended by the factory. Optional 1” and 2”

pleated lters are available and can be used in this unit.

Contact the local Sales Representative for the correct

lter upgrade specication and availability. Consult the

factory for applications using lter types other than the

factory standard or optional product.

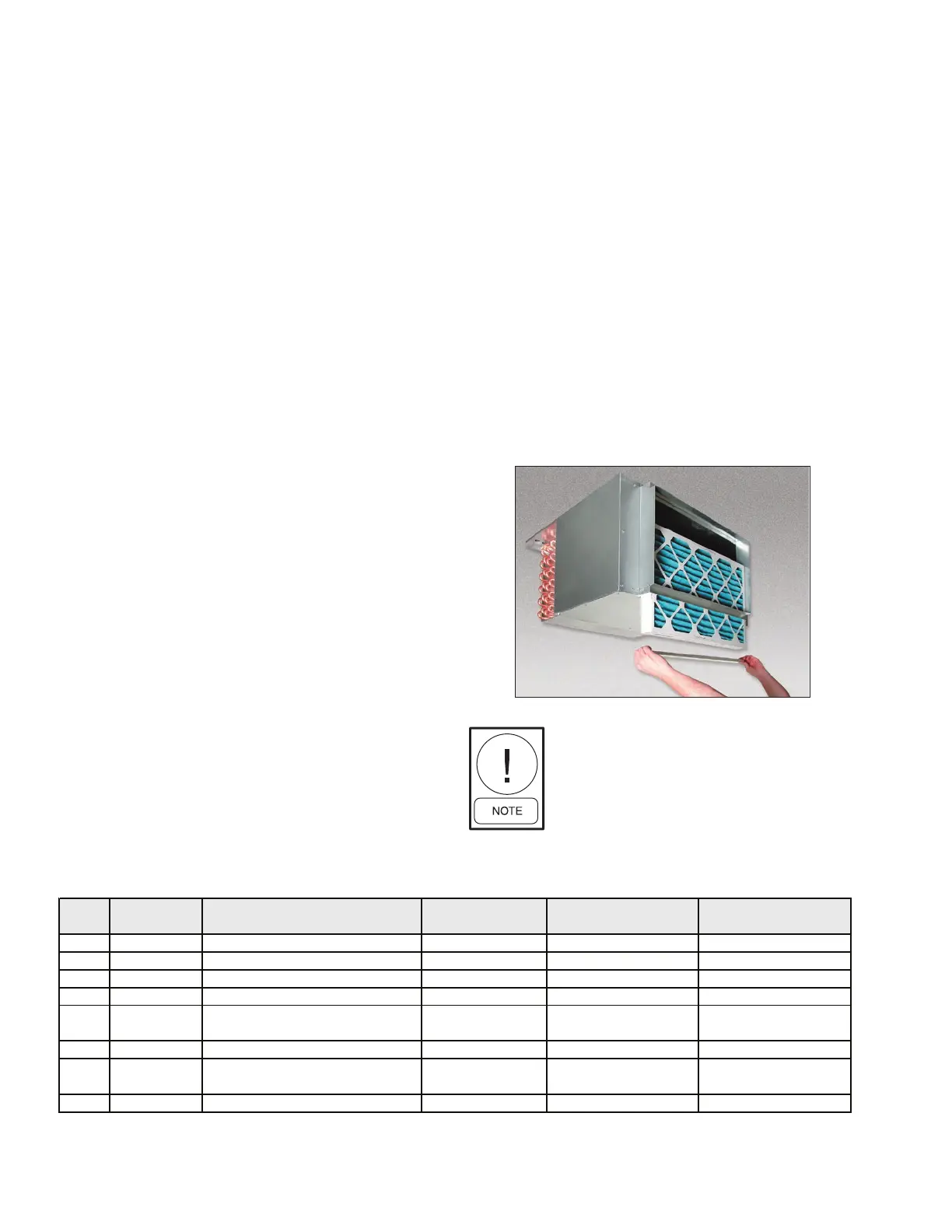

FILTER REPLACEMENT

To replace the lter(s), unscrew the thumb screws

located at the bottom of the lter bracket a few turns

until the lter tray freely slides out. Slide out the used

lter(s) and replace with the new one(s). Reattach the

lter tray to the lter bracket with the supplied thumb

screws.

The lter tray is fully adjustable and

can be rotated 180 degrees if necessary

to ensure a snug t between the lter

and the lter bracket.

Loading...

Loading...