14

Lubrication

Apart from regular checking of the oil level in the lubricating oil

tank, always make sure that there is oil in the compressed air. This

can be checked whenever the rotation unit is free, that is discon-

nected from the drill string. Simply place a plank over the drill-

steel support and blow operating air on to the plank as seen in the

image to the right. After a few moments, the surface of the plank

should become oily, which confirms that lubricant is being carried

to the hammer in the operating air.

The importance of adequate lubrication of the hammer cannot be

over emphasized� Poor lubrication will accelerate wear and ulti

-

mately result in breakdown. The effective lubrication of the DTH

hammer is not always a straight forward matter, owing to wide

variations in operating conditions, for example extreme tempera-

ture differentials between the hammer and the lubricator, water or

foaming concentrate added to the operating air, etc.

Different lubricants have different properties.

Mineral oils have the best lubricating properties and are prefer

-

able in most cases. Mineral base oils have good adhesion proper-

ties and are produced in different viscosity and temperature range

grades.

Since mineral oils have good resistance to water, they are suit-

able for use even when comparatively large volumes of water are

injected into the operating air. In this case, however, the dosage

must be increased.

Other lubricants worth mentioning are the so called “edible” oils,

which consist of vegetable oils, synthetic lubricants of the ester

type, or a mixture between these two. Edible oils can be mixed

with mineral oils, have good lubricating properties and are non

-

toxic.

Please note, use suitable rock drilling tool oil to protect internal

parts if the hammer will be stored for a longer period because a

non-mineral edible oil will hardened and become sticky after a

period of time.

Lubrication consumption

About 1 ml of oil per m

3

of operating air consumed should be the

minimum dosage for bench drilling. As a rule, higher dosages are

needed in water-well drilling.

If the air system has been shut off for a long period of time, it can

take quite some time for the lubricant to reach the hammer. In

such cases, a small amount of oil must be poured directly into the

hammer or air hose before drilling.

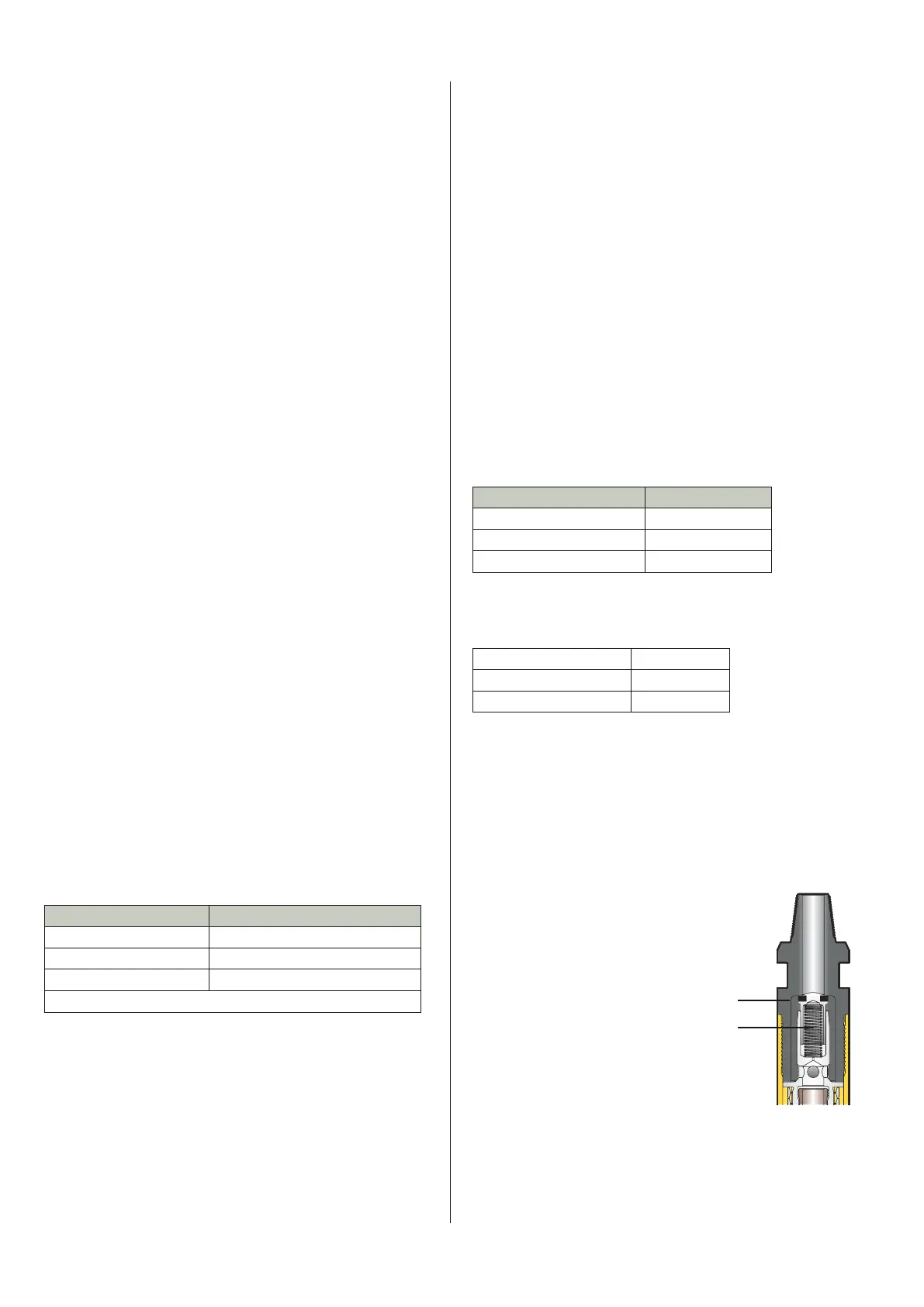

Lubrication consumption

Hammer Dosage (l/s per working hour)

COP M6 0,5–0,8

COP M7 1.9-2.2

COP M8 2.2-2.3

In case of water injection, increase dosage by 0,1–0,2 l/hr.

Both plunger pump and nozzle type lubrication systems are avail-

able.

The plunger pump is relatively insensitive to the viscosity of the

lubricant and gives a more reliable dosage compared with the

nozzle type lubricator. This is of major importance when the ambi

-

ent temperature is low.

N�B� The distribution of lubricating oil through the compressed air

system generally takes place in the form of so-called “wall flow”.

Choice of lubricating oil

For the COP M-Series down-the-hole hammer it is recommended

to use Epiroc COP oil or Matex. When choosing between other

types of lubricants, the oil should have:

• Suitable viscosity (see the table to the right)

• Good adhesion properties

• High film strength

• Corrosion inhibitors

• EP additives

For reasons of water hygiene, lubricating oils used in water-well

drilling should be non-toxic.

The temperature limits given above refer to the temperature of

the oil in the tank, that is the ambient temperature. In cases where

the hammer is powered by warm compressed air at high operat

-

ing pressures, for example when connected to a nearby portable

compressor, the temperature of the operating air must be taken

into consideration. In such cases it may be necessary to choose a

thicker oil than what is recommended in the table.

Thicker oils have beneficial characteristics which can be exploited

in stable temperature conditions, for example underground. In

general, thicker oils have a better film strength and better adhe

-

sion properties, which leads to lower oil consumption.

Ambient temperature Viscosity grade

-20 to +15 °C (-4 to +59 °F) ISO VG 46-100

+15 to 35 °C (59 to 95 °F) ISO VG 100-220

>+35 °C (95 °F) ISO VG 220-350

Recommended lubricants

Epiroc COP oil

Can 10 litres 3115 3125 00

Can pallet 48 x 10 litres 3115 3126 00

Drum 208 litres 3115 3127 00

Lubricating oil tank:

Epiroc COP oil.

Threads and splines:

Copper or zink based thread compound.

O-rings and rubber parts:

Silicone grease (temperature limits -20 to 120°C).

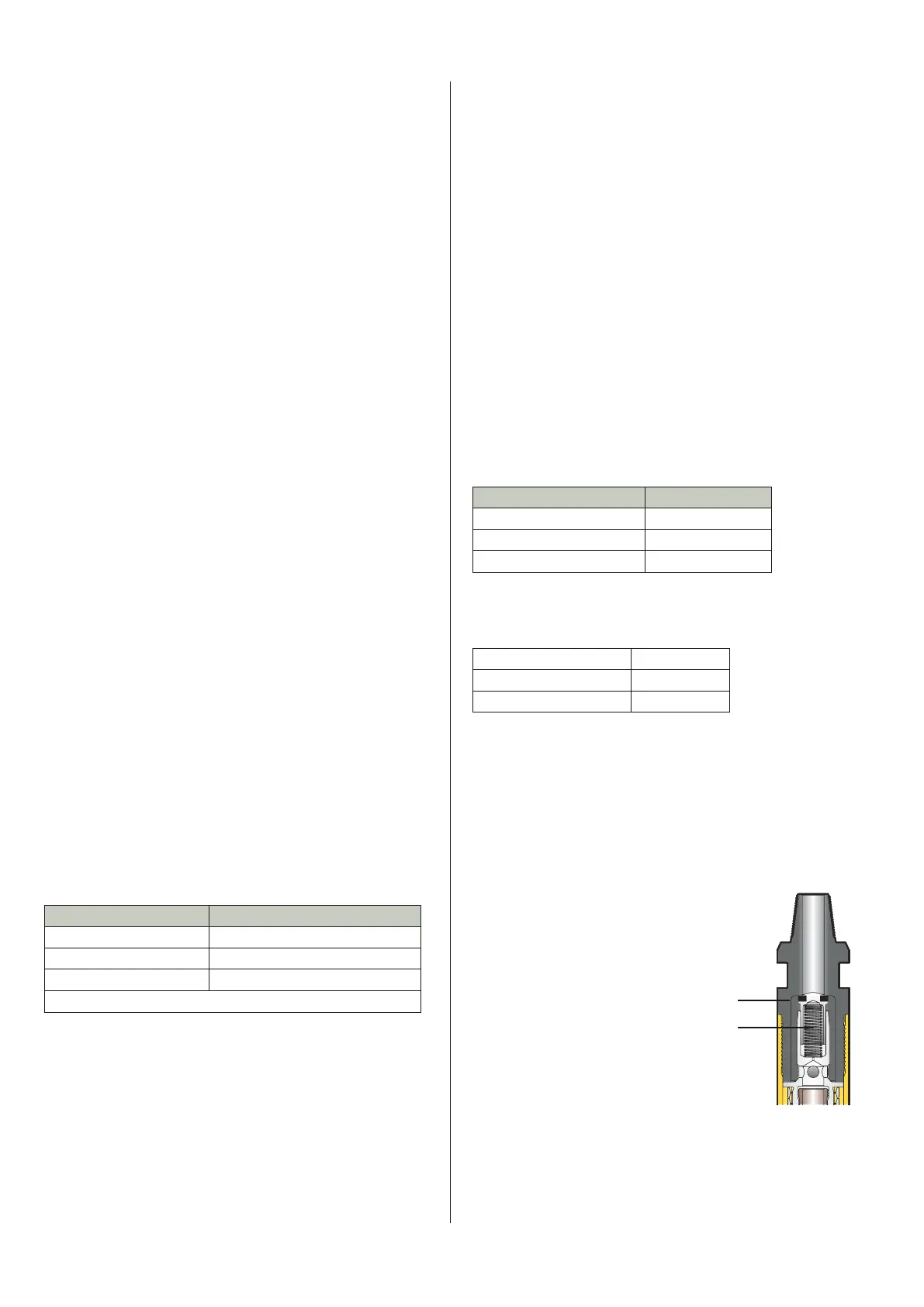

A

B

The check valve and

seal A and spring B

must be fault free

when drilling in water-

bearing formations.

Dirt in the hammer

Stoppages and breakdowns caused by

dirt in the percussion mechanism are

practically inevitable with all rock drills,

and DTH hammers are no exception.

However, it should be remembered that,

while DTH hammers are no more sensi-

tive to dirt than tophammers, there is

obviously a greater risk of dirt ingress in

down-the-hole drilling, especially during

pipe jointing. Any dirt that enters the drill

pipes goes straight into the percussion

mechanism�

All Epiroc COP down-the-hole hammers

contain a check valve that is designed to

Loading...

Loading...