4

Safety

General safety regulations

• Before starting, read these instructions carefully and follow the

pieces of advice that are given.

• Use only authorized parts. Any damage or malfunction caused

by the use of unauthorized parts is not covered by Warranty or

Product Liability.

• Make sure that all warning signs on the rig remain in place and

are free from dirt and easily legible.

• Make sure there are no personnel inside the working area of the

drill rig during drilling, or when moving the rig.

• Always wear a helmet, goggles and ear protectors during drill

-

ing. Also observe any local regulations.

• The exhaust air from air driven hammers and grinding machines

contains oil. It can be dangerous to inhale oil mist. Adjust the

lubricator so that the correct rate of lubrication is obtained.

• Make sure that the place of work is well ventilated.

• Always check that hoses, hose nipples and hose clamps are

properly tightened and secured, and that they are not damaged.

Hoses that come loose can cause serious injury.

• Local regulations concerning air hoses and connections must

always be strictly observed. This is especially the case if the DTH-

hammer is to be operated at pressures above 10 bar (145 psi).

• The machine must not be used for purposes other than those

prescribed by Secoroc (that is mining, quarrying, civil-engineer

-

ing, deep hole, water well and geothermal drilling operations).

Warning symbols

Indicates immediate hazards which WILL result in serious or

fatal injury if the warning is not observed.

DANGER

Indicates hazards or hazardous procedures which COULD

result in serious or fatal injury if the warning is not

observed.

WARNING

Indicates hazards or hazardous procedures which COULD

result in injury or damage to equipment if the warning is not

observed.

CAUTION

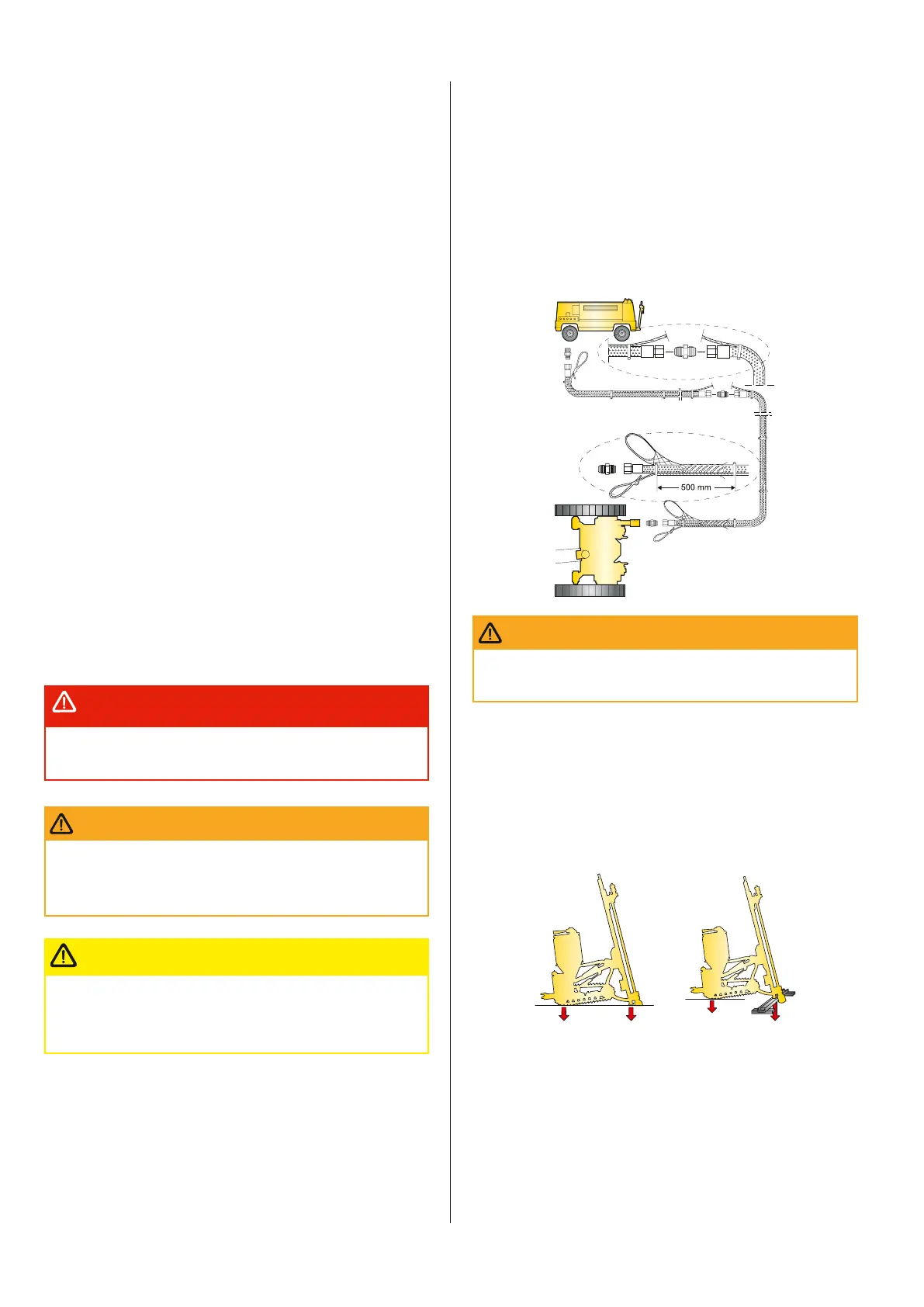

Preparations

Drill Rig and Portable Air

For your personal safety it is very important that the air hoses are

properly connected and secured. Dangerous Compressed Air.

Please follow all rules and guidelines specified in

the operator's manual of each type of equipment

when operating with high pressure drills�

Please follow drill manufacturer's Saftey Specifications.

WARNING

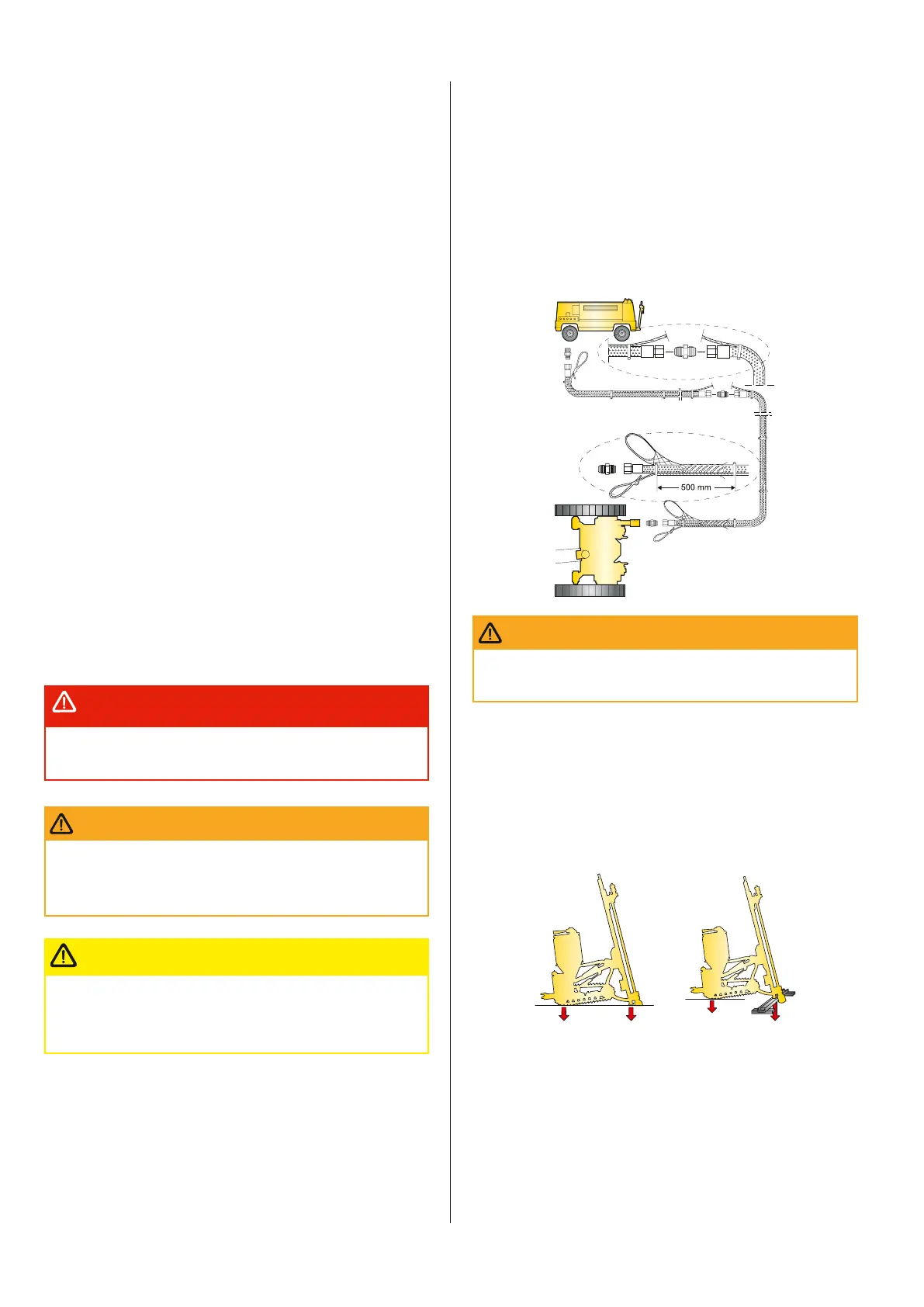

Setting up the rig - 3 points

Three-point set-up with the weight of the rig distributed between

the base of the feed beam and the two rear corners of the rig (A).

As the hole can cave in, the weight of the rig must not be loaded

too near the mouth of the hole. Instead, it should be distributed to

the sides of the hole (B).

If the rig is wheel-bound, it should be raised off the ground com

-

pletely using the jacks, so that all wheels are clear of the ground.

A

B

What drill rig do you need?

The main demands on the drill rig are as follows:

• Variable rotation speed of 0–90 r/min.

• Rotation torque of 750–3000 Nm (75–300 kpm).

• Variable feed force of 3–43 kN (300–4300 kp). The feed must be

strong enough to pull the hammer out of the hole. The weight of

the drill string varies between 9 and 34 kg/m, depending on the

pipe and bit diameters.

Loading...

Loading...