6

Exercise:

Suppose you are drilling at 25 bar with a COP M8 hammer.

Your bit size is 216 mm and the bit button diameter is 19 mm.

What is the recommended starting point for the rotation

speed?

Answer:

A COP M8 hammer at 25 bar provides

2160 strokes per minute.

RPM = (1600*19) / (216*3.14)

= 45 Rpm revolutions/min

B: 300 divided by the bit diameter

You could get a very rough estimate of the RPM simply by divid-

ing 300 by the bit diameter in inches.

Exercise:

Suppose you are drilling with a 8 inch hammer (a 203 mm

hole). What is the recoomended starting point for the rotation

speed?

Answer:

RPM = 300/8.5 = 35 rotations/min

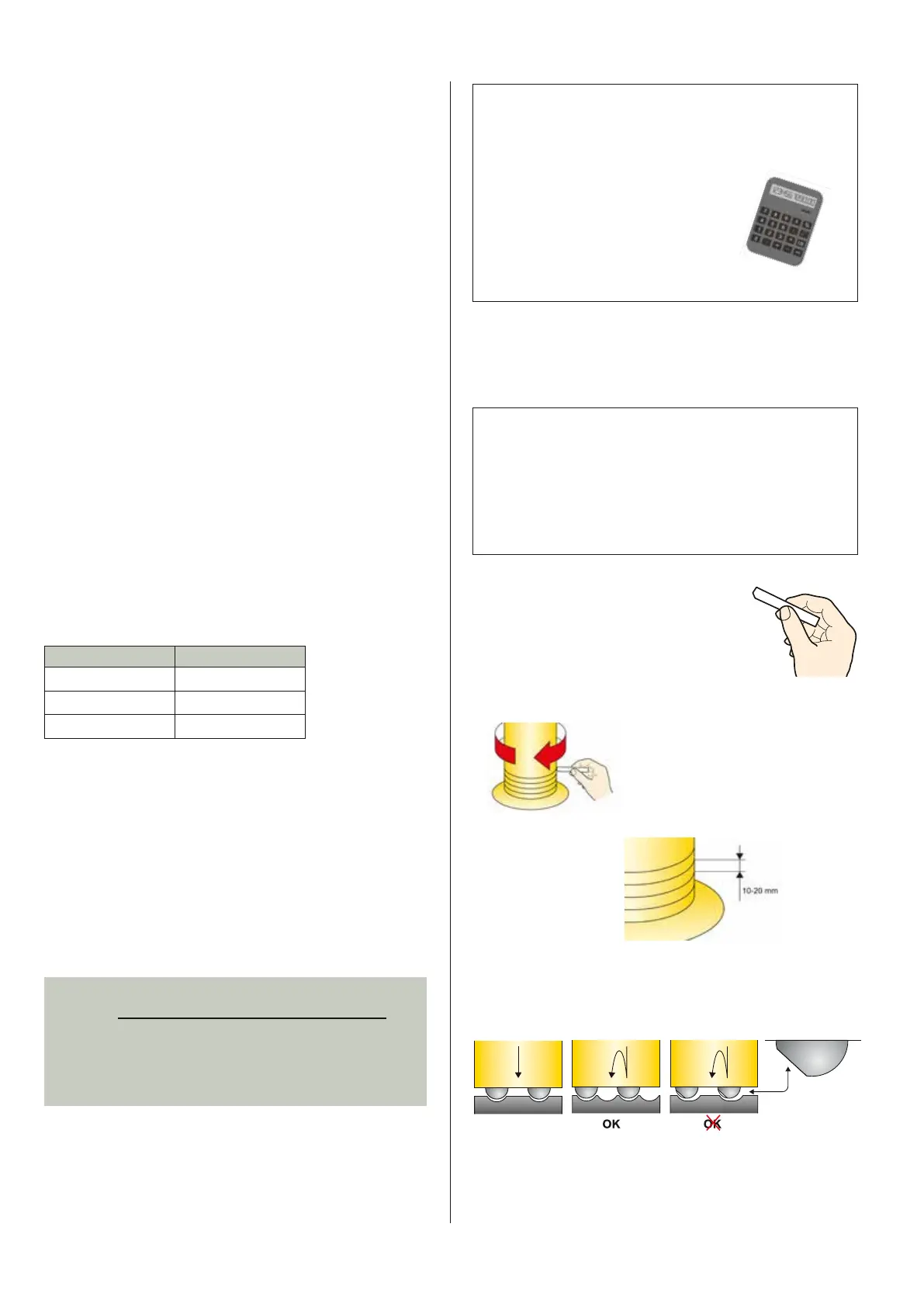

C: Use a piece of chalk

The idea is to set the rotation speed based on

the penetration rate. Follow the instructions

given below.

1) Install a piece of chalk or a soapstone into

a piece of plastic pipe (1m/36" length) or tubing for safety.

2) Scribe a spiral on the drill pipe while

the drill is operating.

3) Measure the distance between

the spirals. If the space is less

than 10 mm the drill RPM should be

decreased. If the space is more

than 20 mm the drill RPM should

be increased. Having adjusted

the settings, repeat the procedure

until the space is be- tween 10

mm and 19 mm.

D: Uneven wear on drill bit buttons

Look out for uneven wear on the carbide buttons.

Comments: The four methods for setting the rotation speed all

give different results. Method A normally suggest the highest

RPM, method B the second highest value, method C the second

lowest value and method D the lowest RPM. Please follow the

instructions below for how to adjust the settings for best results.

Rock type

The general recommendation is to use as much percussion pres-

sure as the rock can take. One might think that you cannot go

wrong if you adjust the percussion pressure to its maximum level.

However, it all depends on how hard the rock is.

Only drilling in hard rock enables maximum energy per blow.

In soft rock the operator has to reduce the percussion pressure

(and thereby the energy), otherwise the energy of the impact will

be reflected as a tensile wave that harms the equipment. Do note

that reducing the percussion pressure in soft rock will not affect

the penetration rates.

How to adjust the setttings

Adjusting the percussion pressure is in most cases a matter of

decreasing the pressure. You should do this if you believe that

the flushing is insufficient or the penetration rates are too high. In

both these cases the drill bit will not be able to rotate. The opera-

tor should pay close attention to the rotation of the drill string.

Rotation

The idea of the rotation is to turn the buttons on the drill bit into a

new uncrushed position for the next impact from the piston.

Recommended settings

The table below presents recommended settings. The settings

depend on the hammer size and bit diameter. The larger the bit

diameter, the slower the rotation speed you should use.

Note that in very abrasive rock formations the rotation speed

should be reduced to avoid excessive wear of the drill bit�

Rotation speed - recommendations

Hammer RPM

COP M6 15–70

COP M7 20-70

COP M8 20-50

How to estimate the rotation speed

Many operators set the rotation speed from experience of similar

drilling situations. However, if you ever find yourself out of refer-

ences, you could set the rotation speed by using any of the four

methods described below. Hopefully they will at least give you a

starting point for your rotation speed.

A: Use a mathematical formula

The factors in this formula are percussive pressure, bit size and

button diameter. The number of strokes per minute is given in

the technical data sheet. Do note that this formula is designed for

rotating the drill bit one button diameter per blow.

bit diameter * 3,14 π

RPM =

strokes per minute * button diameter

+/– 15% depending on rock formation or drill bit design

Loading...

Loading...