8

Safety: Operation

• When drilling on soft or unstable ground, great care must

be taken because the flushing air from the hammer can erode

the material around the drill hole, and so undermine the

ground beneath the drill rig. This can pose a great danger to

personnel and risk damaging the equipment.

• Keep your hands and clothing well clear of the hammer

and drill string when it is rotated. Entanglement can result in

serious injury.

DANGER

• Take great care when jointing drill pipes. Make sure there

is no danger of your fingers being pinched or clothing being

entangled when the drill string is rotated.

• When a pipe wrench is used during jointing, there is a risk

of the wrench fiying off and causing injury when rotation is

applied.

• Always wear safety glasses during drilling!

• Keep your clothing, hair etc. well clear of rotating compo-

nents! Careless ness can result in serious injury.

• The exhaust air from the hammer (and also from the back-

head if a unit for extra flushing is fitted) has a very high velo-

city. Objects such as small stones, drill cuttings, sand, earth

and oil residue that are transported in the flushing air can

cause serious injury to unprotected eyes. Pay special attention

to this danger during collaring, when a jetsub or hydrocyclon

are in use, and when the hammer is fed through the drill steel

support or down into the hole.

WARNING

• Always wear ear protectors during drilling.

• The injection point for water and foaming concentrate should

always be located after the main shut-off valve on the rig.

If not, there is a danger of the mixture being pumped back

through the main air line and into the compressor. This could

seriously damage the compressor.

CAUTION

the drill string is lifted from the hole. If the hammer is going to

be stored for a long time, it should be dismantled and all parts

cleaned and oiled thoroughly.

If you would like to know more about flushing media or have any

questions regarding foaming concentrates not supplied by Epiroc,

please consult your nearest Epiroc representative for advice.

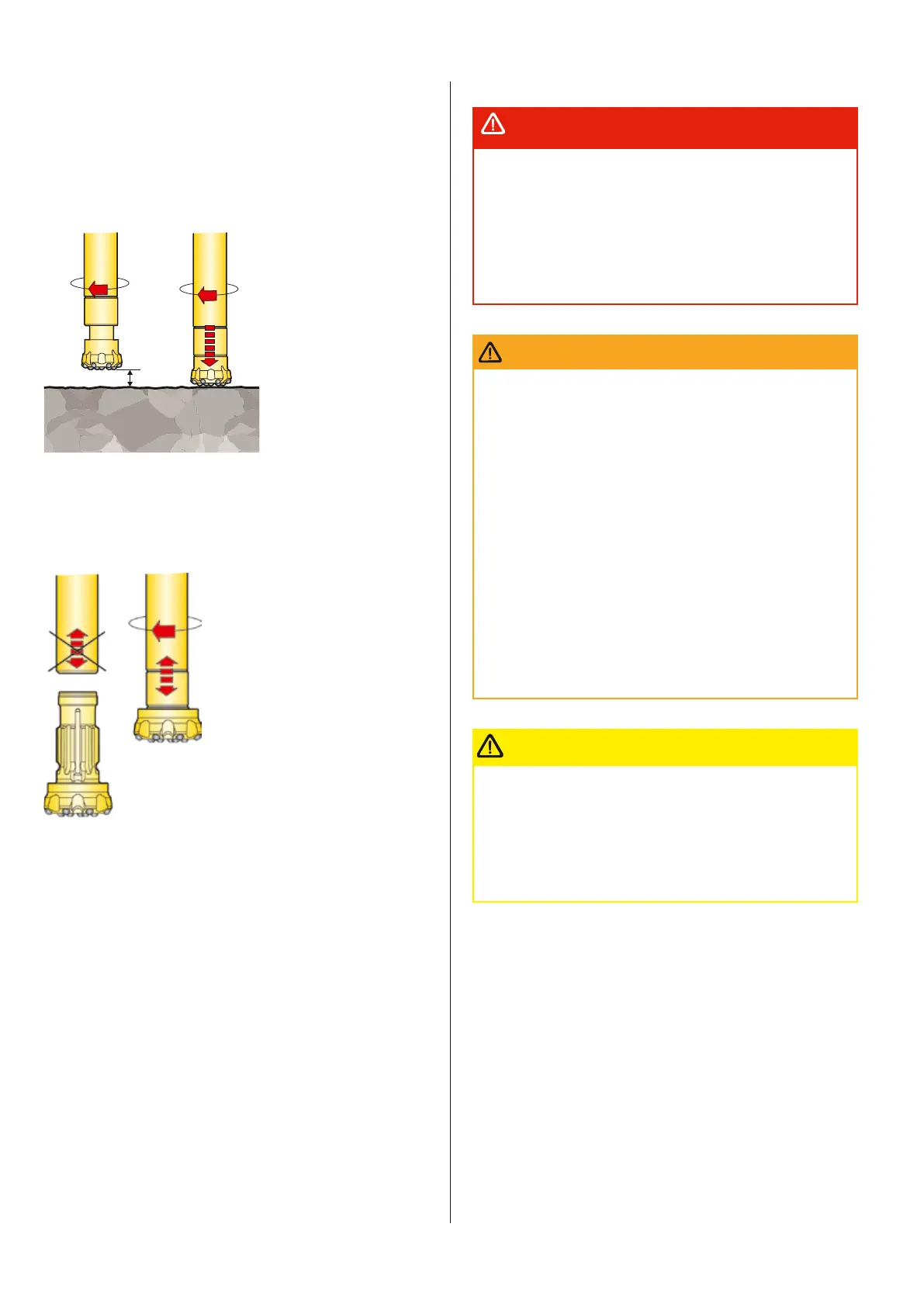

How to collar the hole

5 cm

1) Feed the hammer down-

ward until the drill bit is

about 5 cm from the

collar ing point.

2) Start rotation to the

right at low speed (crep

ing).

3) Feed the hammer on

to the rock using minimal

feed force, so that the bit

is pressed into the ham

-

mer, and into the impact

position.

4) Start collaring the hole

with reduced impact and feed, until the bit has entered the rock.

5) Open the impact mechanism control fully and adjust the rota

-

tion and feed so that the hammer drills smoothly and steadily.

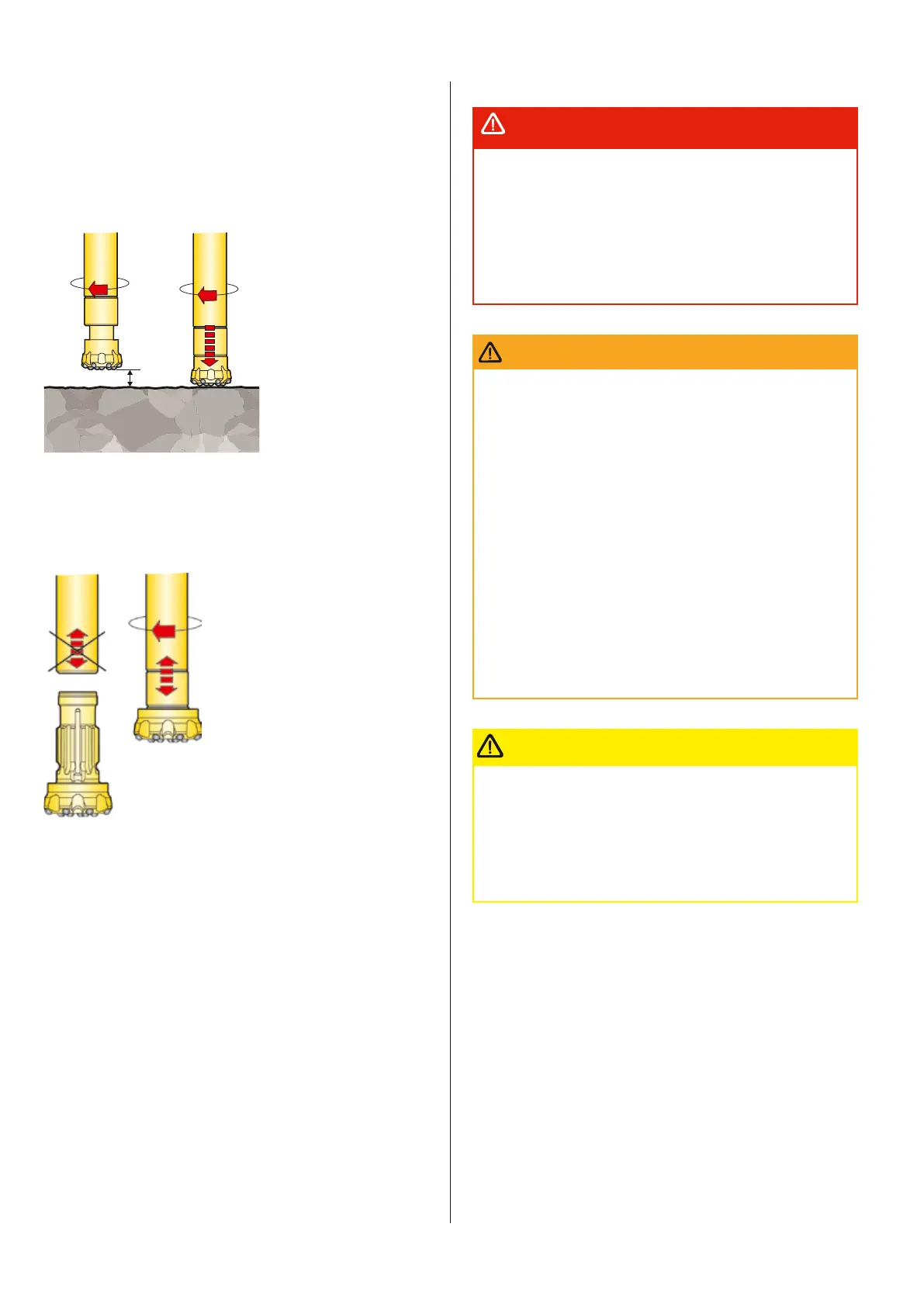

Always rotate to the right!

DTH hammers must always be

rotated to the RIGHT during drilling

(clock wise), even when the hammer

is not operating� Rotation to the

right should be switched on as long

as other operations are in progress

with the hammer in the hole.

When breaking the joints between

drill pipes, bear in mind that the drill

string must not be rotated anti -

clockwise any more than is abso

-

lutely necessary.

Left-hand rotation (or no rotation)

will cause the driver chuck to loosen,

which could mean losing the drill bit

(or even the entire hammer) down

the hole. Inadequate feed pressure

can loosen threaded joints to back

-

head, chuck and pin connection.

Remember:

• Always switch on rotation to the right before starting the feed or

hammer.

• Let the hammer rotate to the right (clockwise) even during

lifting or lowering of the hammer.

Do not switch off rotation to the right until all other functions have

been switched off.

Loading...

Loading...