3

Introduction

General info

The down-the-hole hammer is a percussion hammer drill. The

hammer works down the hole at the end of the drill string, where

the impact piston strikes the drill bit directly.

Compressed air is led to the hammer via the rotation spindle and

drill pipes. Exhaust air from the hammer is discharged through

holes in the drill bit and used to flush clean the drill hole. Rotation

is provided by a rotation unit on the feed beam and transmitted to

the hammer via the drill pipes. The drill pipes are threaded so that

the drill string can be extended as the hole becomes deeper. Feed

force is also transmitted to the hammer via the rotation unit and

drill pipes.

How the hammer works

The Secoroc COP M6, M7 M8 down-the-hole hammers and drill

bits operate at the bottom of the hole as one unit.

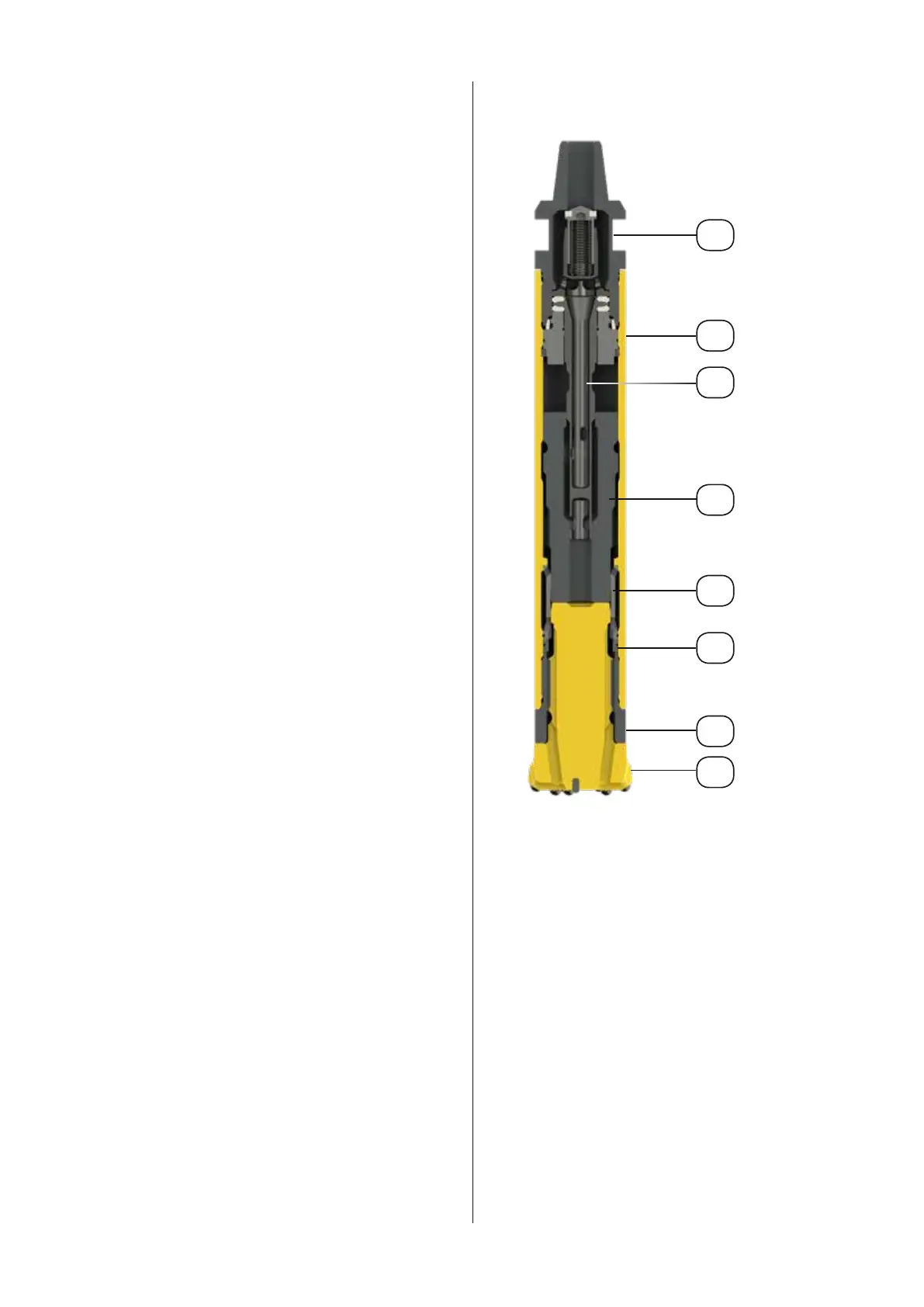

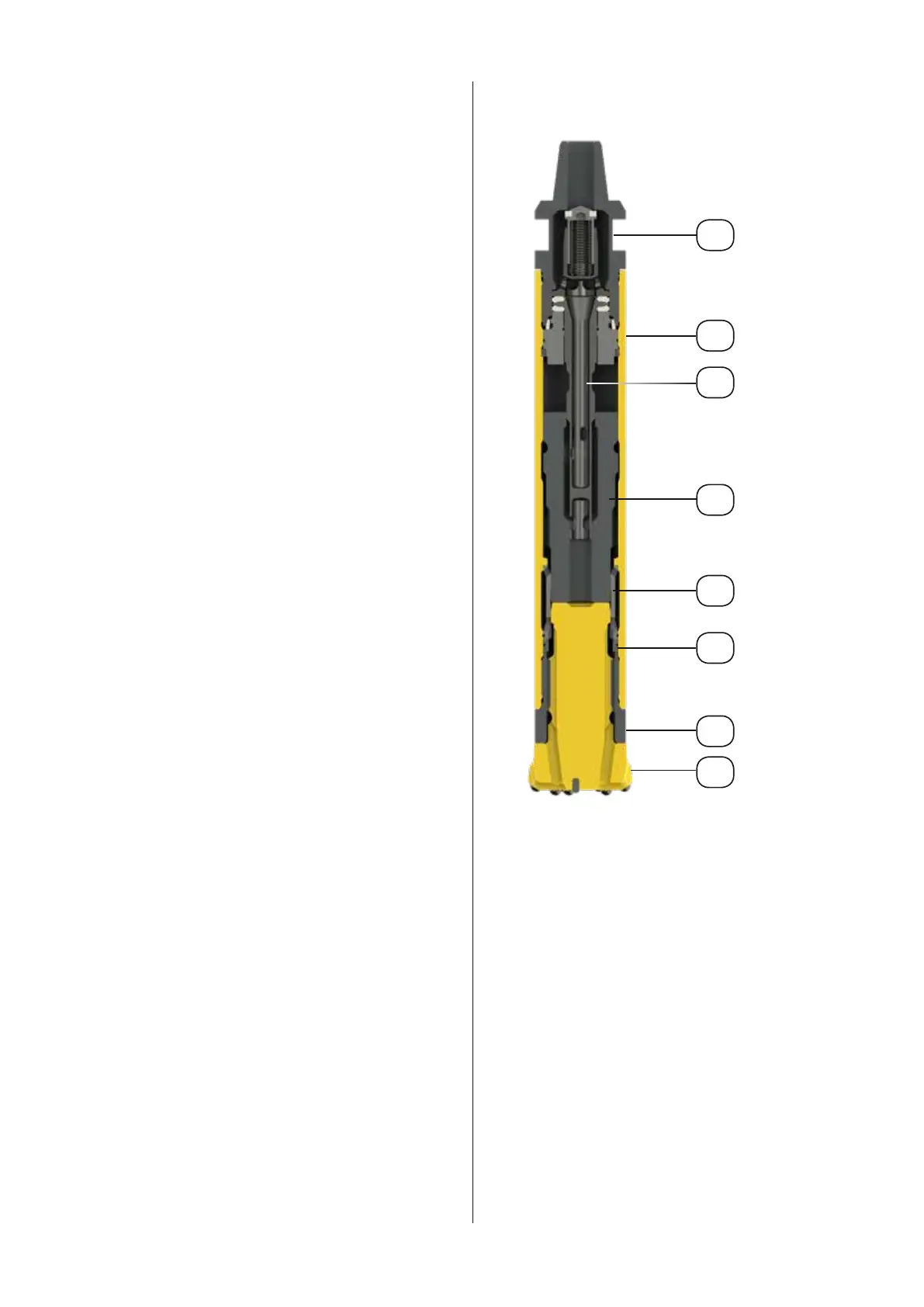

A driver chuck (2) threads into the front end of the casing (7). The

splined union between the driver chuck and drill bit (1) transmits

rotation to the drill bit. The front end of the driver chuck trans

-

mits feed force to the drill bit. The split stop ring (3) limits axial

movement of the drill bit. The check valve (8) prevents water from

entering the hammer through the drill bit when the compressed

air supply is shut off.

When feed force is applied, the drill bit is pushed into the ham

-

mer and pressed against the front of the driver chuck. The impact

piston (5) strikes the shank of the drill bit directly. The passage

of compressed air through the hammer is directed by the piston,

control tube (6) and bit bushing (4), which all have regulating

ducts. A built-in damping chamber cushions the piston return

stroke and increases the impact frequency.

After the compressed air has imparted most of its pressure en

-

ergy to the piston, it is led as exhaust air through airchannels on

the splines of drill bit and chuck. The exhaust air then emerges as

flushing air through holes in the drill bit head. This gives efficient

transportation of cuttings out of the drill hole

When the hammer is lifted off the bottom of the hole, the piston

drops into the air blowing position. This disengages percussion

and gives air blowing only, that is, a large volume of air flows

straight through the hammer and drill bit. During drilling, air

blowing starts if the drill bit loses contact with the bottom of the

hole. The hammer starts operating again as soon as the bit is

pressed back against the driver chuck. Air blowing is used when

powerful flushing of the drill hole is required, and in certain dif

-

ficult drilling conditions.

Friction between the drill pipes and the hole wall can sometimes

reduce the penetration rate. This can often be counteracted by

increasing the air pressure to give more impact power and faster

penetration.

8

7

6

5

4

3

2

1

Loading...

Loading...