16

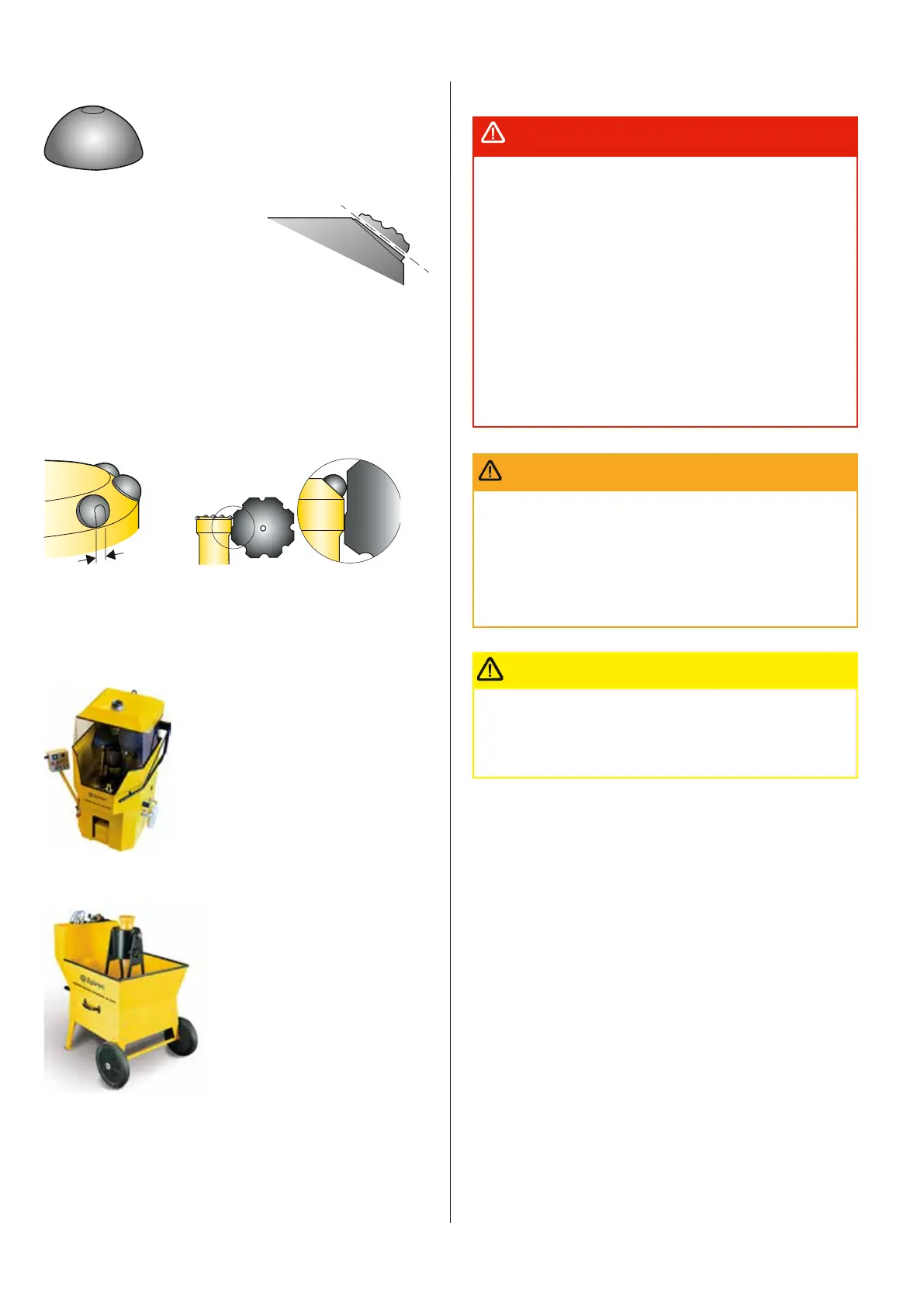

Do not grind away too much cemented carbide

Do not grind too much on the top of the

buttons. Let a few millimetres of the wear flat

remain on top of the button.

Always grind broken buttons flat

A drill bit can remain in service as

long as the gauge buttons maintain

the diameter of the bit. Fractured

buttons must always be ground flat

to prevent chips of cemented carbide

from damaging the other buttons.

Avoid grinding the perimeter

Gauge-button anti-taper has to be removed by grinding, although

excessive reduction of the bit diameter should be avoided. Leave

about 2 mm of the wear flat. If necessary, remove some of the bit-

body steel below the gauge buttons, so that a clearance (taper) of

0,5 mm is maintained. If the flushing holes start to deform, open

them up with the aid of a rotary burr or steel file.

2 mm

Min

0,5

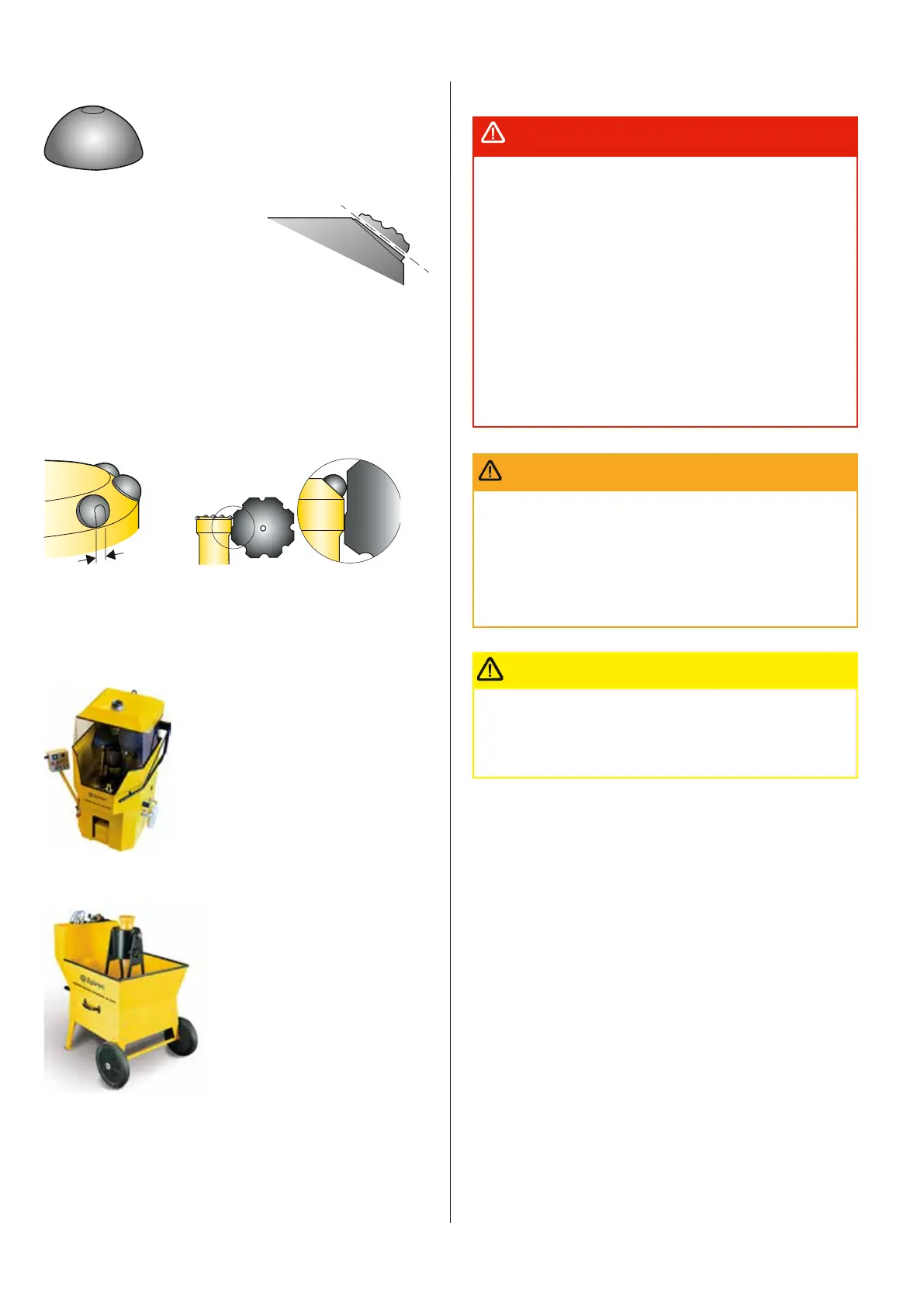

Grinding equipment

Grind Matic BQ3-DTH

For “permanent” grinding stations, a

mechanized stationary grinding machine

is available, the Grind Matic BQ3-DTH. It is

equipped with automatic feeding devices

and grinds both the cemented-carbide

buttons and the bit-body steel in one

operation. The machine uses diamond-

impregnated grinding wheels.

Grind Matic Manual B-DTH

The grinding machine Grind

Matic B-DTH is a mechanized

air-powered grinding machine for

button bits. It is mounted in a steel

box-barrow, which can be wheeled

easily around the work site. The

Grind Matic Manual B-DTH uses

diamond-impregnated grinding

wheels.

Safety: Service

• Take great care when breaking the driver chuck joint using

the bit removal tool in combination with reverse rotation.

If the shaft of the tool is not locked or touching the edge

of the feed beam, the shaft can turn with great force when

breaking the driver chuck joint.

• Blows against hammer or bit can cause fragments of metal

to fly. Always wear goggles when breaking joints.

• Never disassemble the spring unit if the friction springs

may be preloaded.

• Before grinding, always check the flushing holes of the drill

bit for traces of explosive. Contact with the grinding wheel

can cause the explosive to explode causing serious or fatal

injury as well as damage to the equipment.

• To clean the flushing hole, use only a wooden rod, copper

wire or fiushing water.

DANGER

• Take great care when handling the drill bit. Mind your fingers!

• When removing and fitting exhaust tubes, always wear

protective goggles, gloves and appropriate protective clothing.

Carelessness can result in injury to the eyes or other body parts.

• Foot valves are brittle. Heavy blows can deform or disloca-

te the exhaust tube, with the risk that it would then obstruct

the movement of the impact piston.

WARNING

• Always wear ear protectors, protective clothing, gloves and

goggles when grinding.

• Use a dust extraction system or an approved dust mask.

This is of special importance when dry grinding indoors.

CAUTION

Loading...

Loading...