9

Service

How to break the driver chuck joint

The following method is commonly used for breaking the driver

chuck joint�

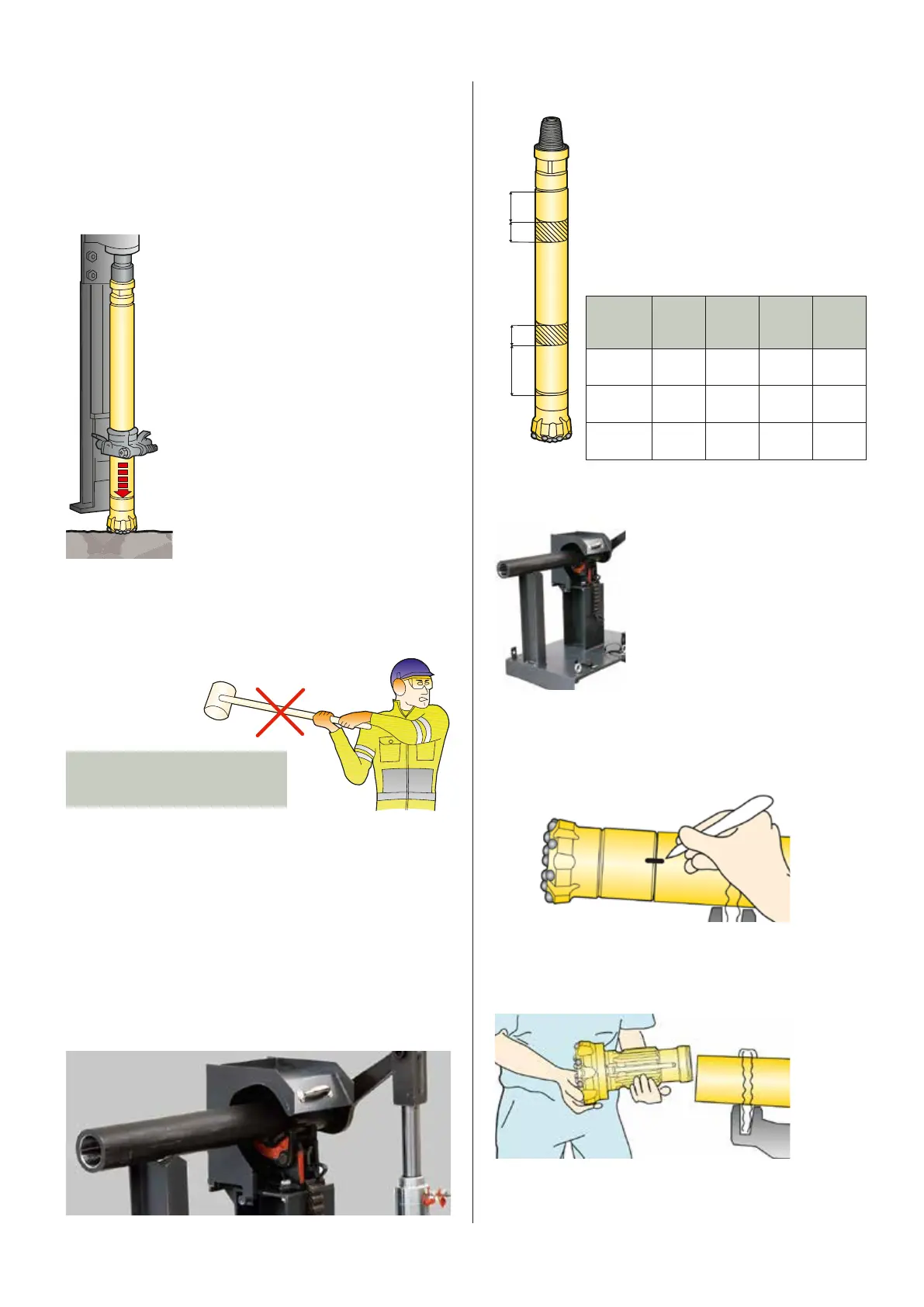

Using percussion

Run the hammer into the rock or a thick plank.

1) Apply light feed force.

2) Carefully start the impact mechanism of the

hammer.

3) Stop the impact mechanism as soon as the

driver chuck joint “cracks”.

4) Run the hammer up the feed beam to a

suitable working height, and unthread the

driver chuck and drill bit.

N�B� Beware of the weight of the drill bit. It

could be too heavy to hold.

Caution: When using gripper jaw or hydraulic break-out wrench

on drill rig, make sure jaws are in proper location. If not, this

could lead to premature damage on casing or bit.

Important:

Never use a sledge-hammer

on down-the-hole COP hammers.

Tools for removing the drill bit and

the backhead should revert to drill rig

specifications and tool accessories

Backhead and chuck removal can be serviced with a

hydraulic make/break-out bench

The threaded connections of the driver chuck and backhead can

become very tightly tensioned during drilling. There are special

tools for removing the bit and backhead from the casing of the

COP hammer, and these should be used whenever possible.

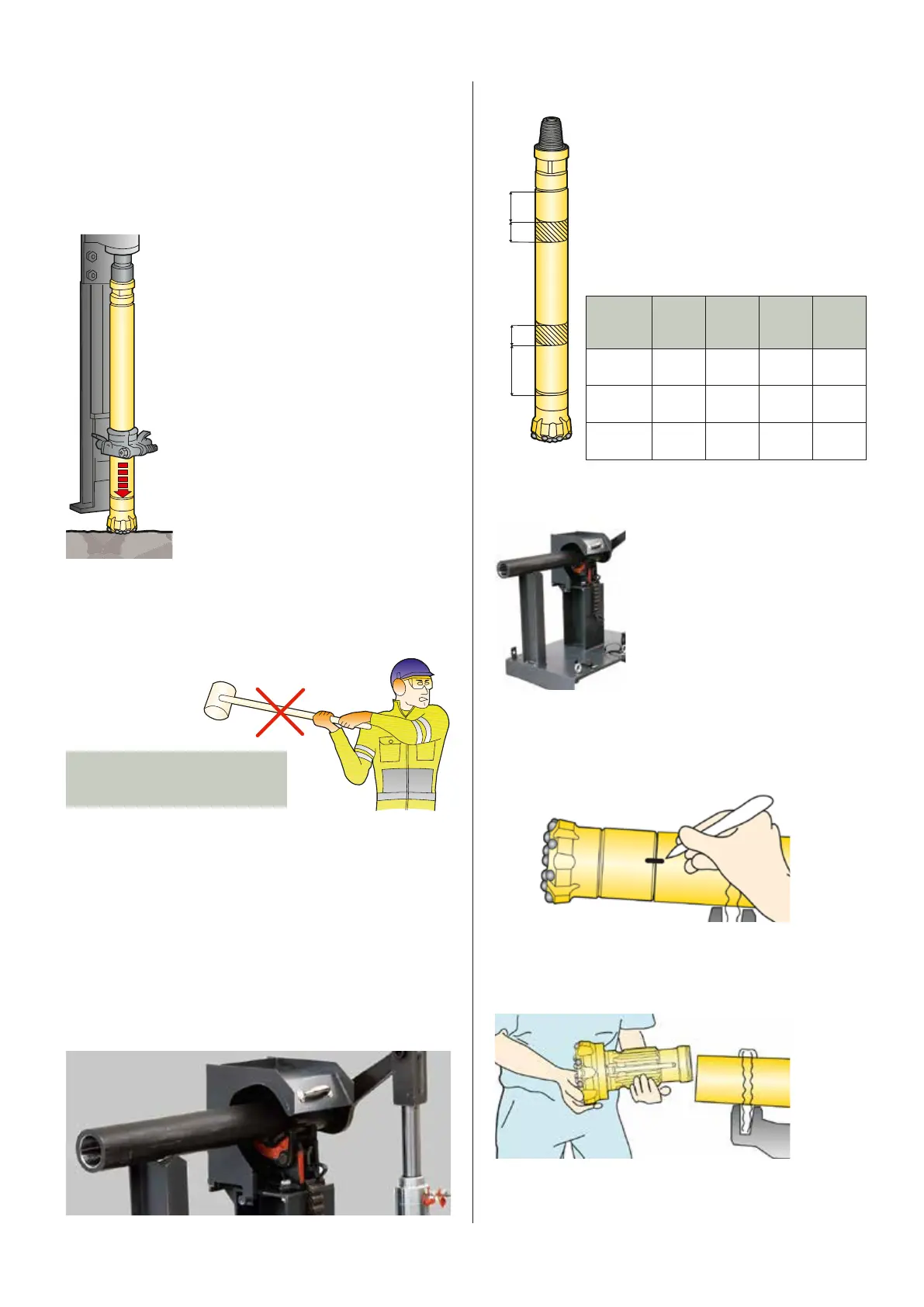

How to loosen the threads of the hammer

A

B

C

D

If special tools like chain wrenches or other types

of wrench are used to break the hammer joints,

then the tool must be attached around the

hammer casing at the highlighted areas (B and C)

in the figure to the right. Do not attach at other

points!

Failure to attach the wrench as illustrated may

result in damage to the casing. Any such damage

will not qualify for compensation.

Hammer

A

mm

(inch)

B

mm

(inch)

C

mm

(inch)

D

mm

(inch)

COP M6

114

(4,5)

55

(2,2)

126

(5,0)

170

(6,7)

COP M7

155

(6.1)

55

(2.2)

170

(6.7)

207

(8.1)

COP M8

115

(4.5)

290

(11.4)

150

(5.9)

320

(12.5)

Breakout bench

It is always most convenient to break the

hammer threads on the rig. For circum-

stances, when the threads cannot be

broken or tend to get stuck, there are two

types of breakout bench available.

Please contact Epiroc Drilling Tools for the Breakout bench part

number.

How to replace the drill bit

1) If you are about to disassemble the whole hammer, make sure

to mark the casing so you will know which end is the backhead

side and which is the driver chuck side. Once the hammer has

been disassembled it is hard to tell which end is which.

2) When the chuck threads have been loosened, remove the driver

chuck from the casing along with the drill bit and retaining rings.

Loading...

Loading...