5

Getting started

In order to get optimal drilling the impact, feed and rotation must

harmonize. Start off by setting the percussion pressure on the

compressor. Secondly, set the rotation speed. Thirdly, set the feed

force. Adjust your settings continuously. The goal is to have the

drill string rotate evenly without jerks or jamming, and a steady

penetration rate.

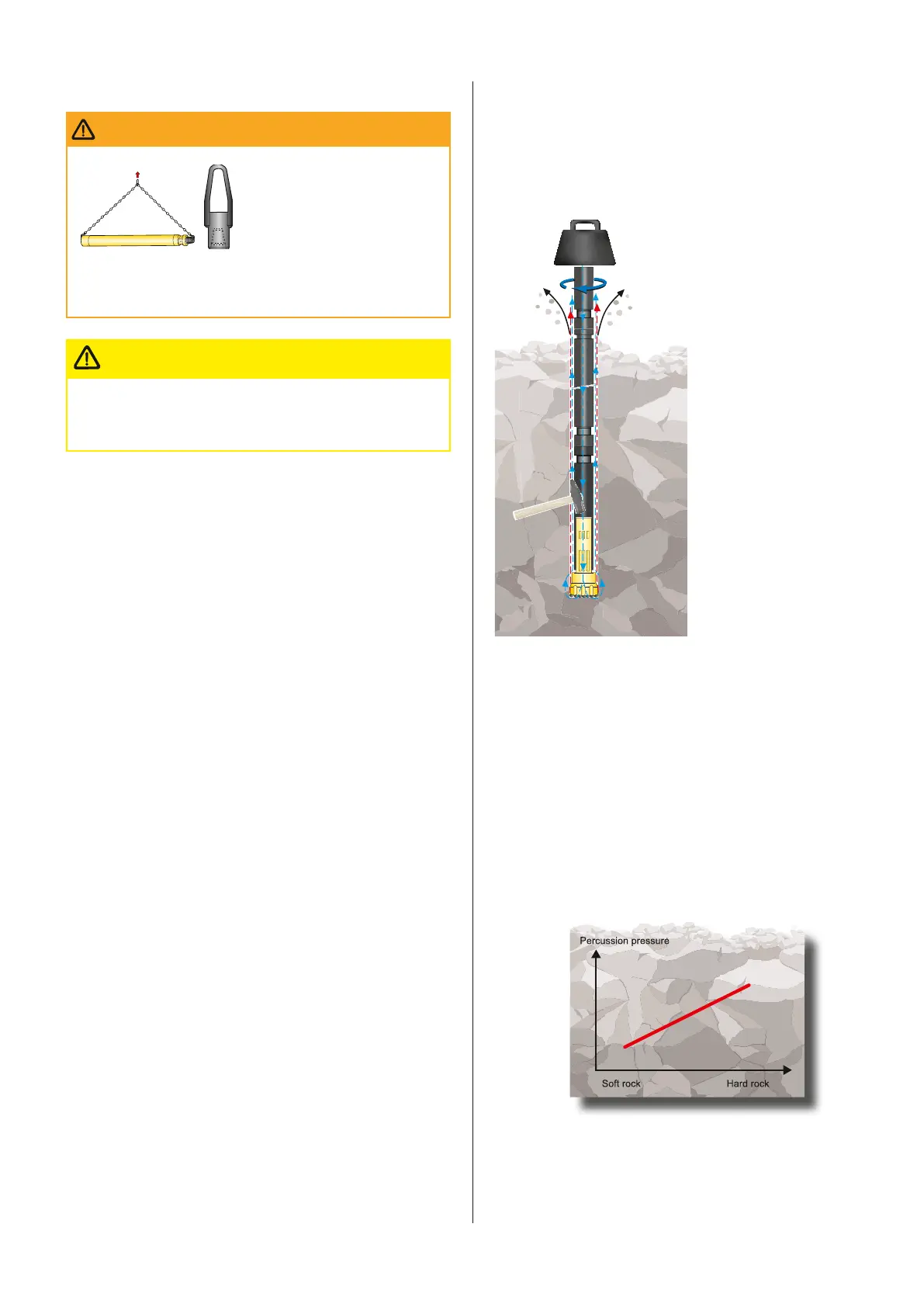

The impact depends on the percussion pressure. The higher the

percussion pressure, the faster and the harder the impact you will

get.

Recommended settings

The pressure depends on the depth and the type of rock that the

operator is about to drill.

Depth

With modern compressors that provide pressures up to 35 bar,

the impact energy is initially too high. If the operator were to use

maximal pressure the equipment would be damaged. Therefore,

the operator normally uses a lower pressure down to depths of

70–100 metres (by then you will have a counteracting pressure of

2–4 bar).

The illustration shows the principled correlation between

percussion pressure and rock hardness.

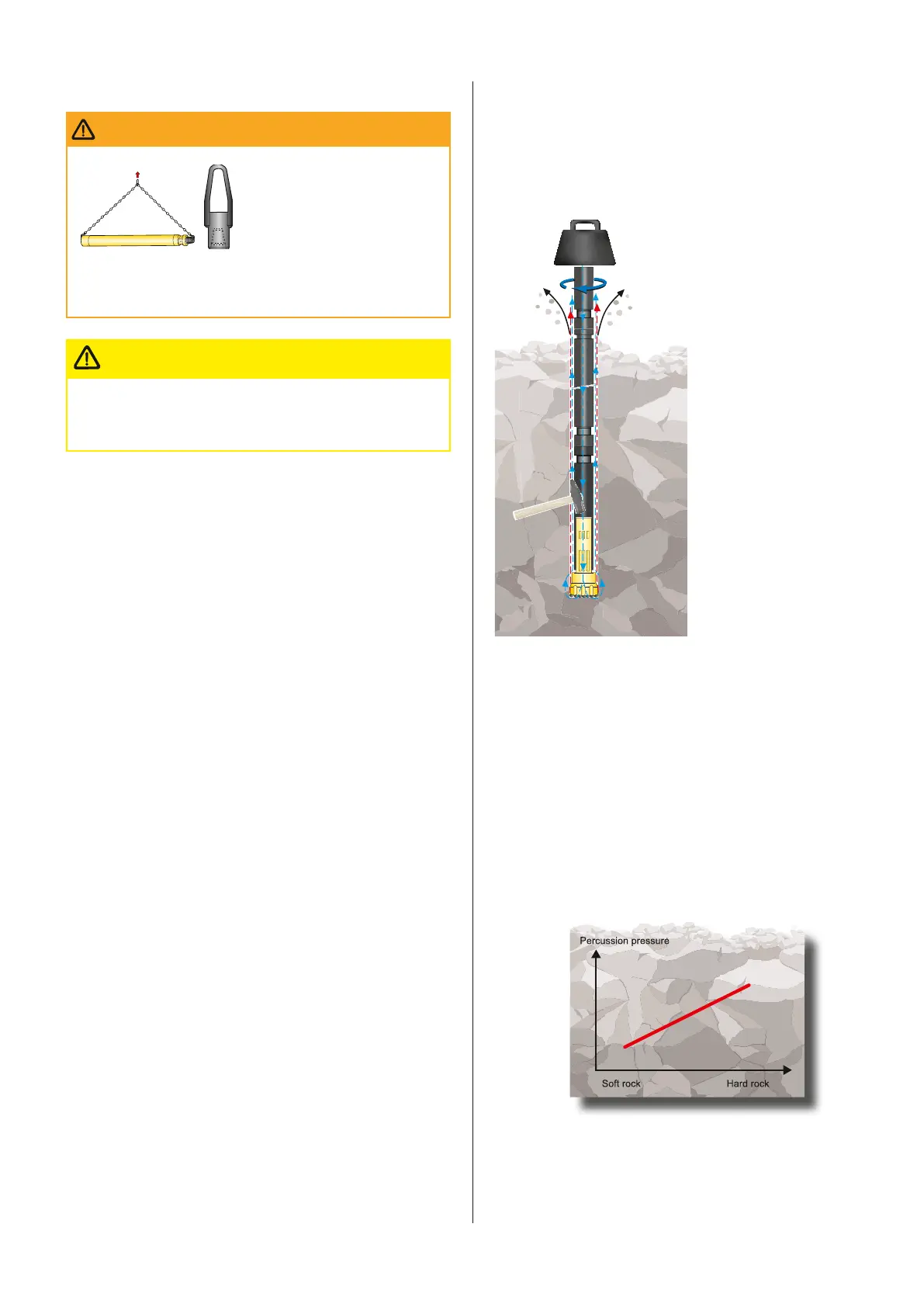

Safety: Preparations

•

Take care when handling the

hammer, it is very heavy. The

hammer and its internal

components are heavy and

difficult to handle, especially in

the case of the larger hammers.

•

When you lift the hammer using mechanical lifting equip-

ment, sling the hammer as shown in the figure. Alternative-

ly, a lifting-eye coupling can be screwed on to the backhead.

WARNING

•

Always check the condition of drill string components. Bent

or worn pipes can cause damage and excessive wear to the

hammer and rig

.

CAUTION

Operation

Pre-Torque

Simply put, it is the amount or force applied to the back-head and

chuck to lock by compression internal components of the ham-

mer. Each threaded part will be individual torqued tight, with rig,

or hydraulic bench before operating!

A common practice in the field is to use the rotary head, which

can never supply enough torque for the specification need to keep

internal parts tight.

Golden rule: torque threaded joints between (40.5-54 kN-m / 750-

1,000 lbf-in) per inch or hammer dia.

Example: 5"/127 mm DTH hammer

5 x 750 - 1,000 ft�lbs = 3750 - 5000 lbs�in

127 mm x 40�5 - 54 Nm = 5143�5 - 6858 Nm

Example: 8"/203 mm DTH hammer

8 x 750 - 1,000 ft�lbs = 6,000 - 8,000 lbs�in

203 x 40�5 - 54 Nm = 81349 - 10962 Nm

The four basic parameters of percussive drilling are impact, feed,

rotation and flushing. In the following sections we will take a look

at how you can adjust your settings to achieve best possible drill

-

ing results.

Loading...

Loading...