EPSON Stylus CX4900/CX4905/CX5000/DX5000/DX5050/CX5900/CX6000/DX6000/DX6050 Revision A

DISASSEMBLY/ASSEMBLY Printer Section 161

4.4.24 Ink System Unit

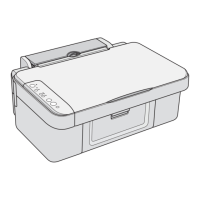

External view

Figure 4-47. Removing Ink System Unit

Part/Unit

that should be removed before removing Ink System Unit

Document Cover / Panel Unit / Scanner Unit / Housing, Upper / Housing, Lower /

Main Board Unit / ASF Unit / Holder Shaft Unit / CR Guide Frame / CR Motor /

CR Scale / Carriage Unit / Front Frame

Removal procedure

1. Release the Ink Tube from the groove on the downside of the Cap Frame.

2. Remove the screw (x1, ) that secures the Cap Unit.

3. Slide the Cap Unit to the inside of the Main Frame, and release the tabs (x2,

) of the Cap Unit from the Main Frame.

4. Release the Carriage

Lock from the notch of the Main Frame.

5. Carefully release the tabs (x3, ) that secure the Pump Unit to the Main

Frame, and remove the Pump Unit.

6. Remove the whole Ink System from the Printer Mechanism, and remove the

gears (x4) and the Pump Pulley.

Guide Pins

Right Side

C.B.P 3x8 F/Zn (4±1kgfcm)

Sealing Rubber

Head Cleaner

Lower right side

Tabs

Cap Unit

Groove

Pump Unit

Compound Gears 27.2, 19.2

Change Lever

Tabs

Guide Pins

Notch and Carriage Lock Position

C A U T I O N

Do not touch or damage the Sealing Rubber or the Head Cleaner

when performing the following work.

Mark the connection location before removing the Ink Tube.

C A U T I O N

When removing the Ink System Unit, be careful not to drop the

Change Lever and Compound Gears 27.2, 19.2.

When installing the Ink System Unit, follow the steps described below.

1. Place the Carriage Lock inside the notch of the Main Frame as

shown in the figure.

2. Match the guide pins (x2, ) of the Pump Unit with the

positioning ho

les (x2) of the Main Frame.

3. Match the guide pins (x2, ) of the Cap Unit with the

positioning ho

les (x2) of the Main Frame.

4. Place the Ink Tube into the groove, and install the Ink System

Unit.

A D J U S T M E N T

R E Q U I R E D

After removing/replacing the Ink System Unit, perform the

adjustment referring to Table 5-1."Required Adjustments" (p172)

Loading...

Loading...