Rev.B Maintenance, Inspection, Lubrication, and Cleaning 5-1

TM-L90 Service Manual

Confidential

Chapter 5

Maintenance, Inspection, Lubrication, and Cleaning

Periodic Maintenance or Inspection

There are no parts in this product that require periodic maintenance or inspection.

Lubrication

There are no parts in this product that require periodic lubrication.

Lubrication is required during disassembly and assembly. Observe the instructions on

lubricants and lubrication points described in Chapter 3, “Disassembly and Assembly.”

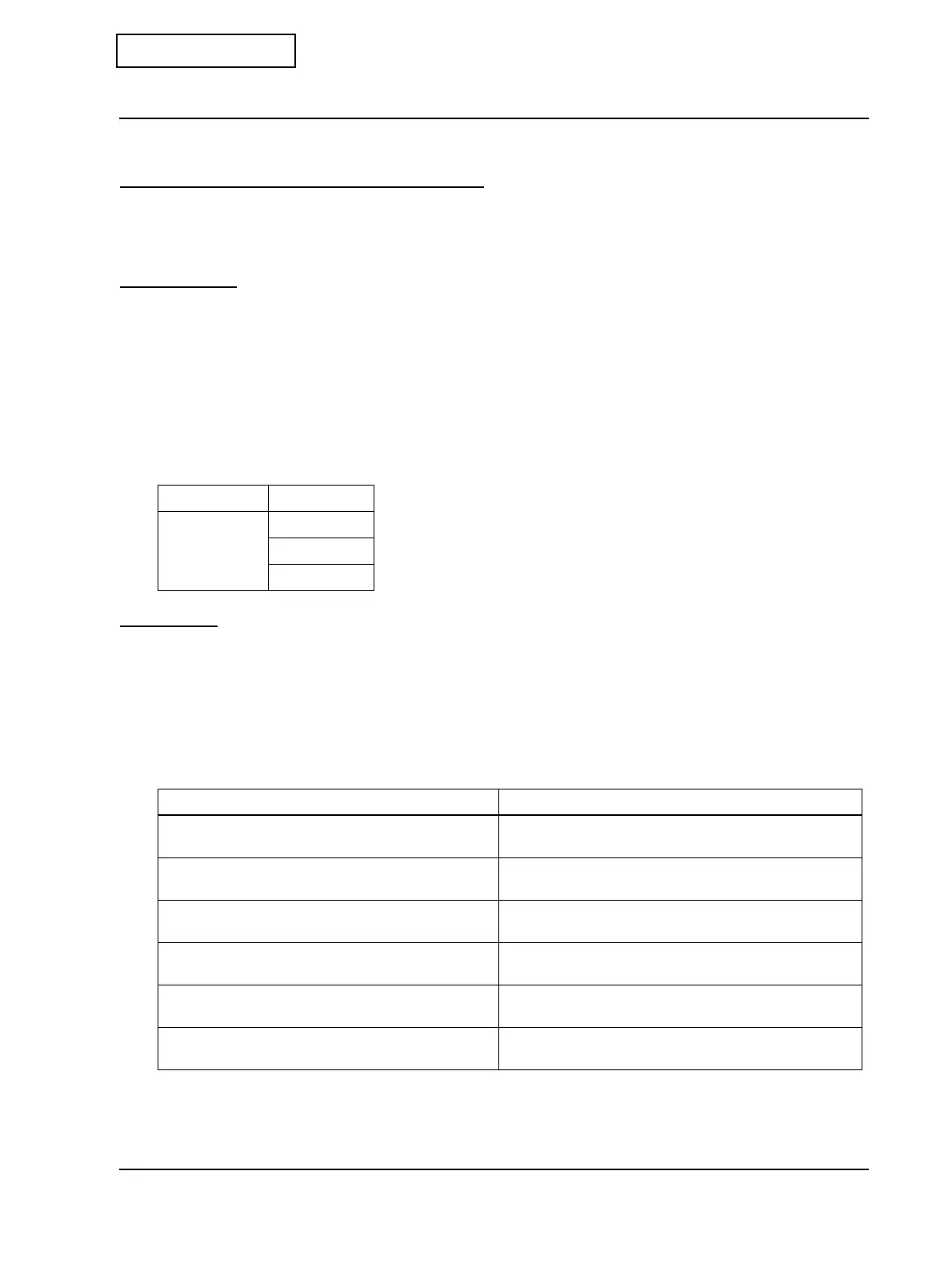

The table below lists the lubricants used in this product.

Cleaning

Recommended Cleaning

It is recommended that you perform the following cleaning during repair. Observe the

precautions in the front of Chapter 3 before cleaning.

Table 5-1 Lubricants

Type Name

Grease G-15

G-36

G-45

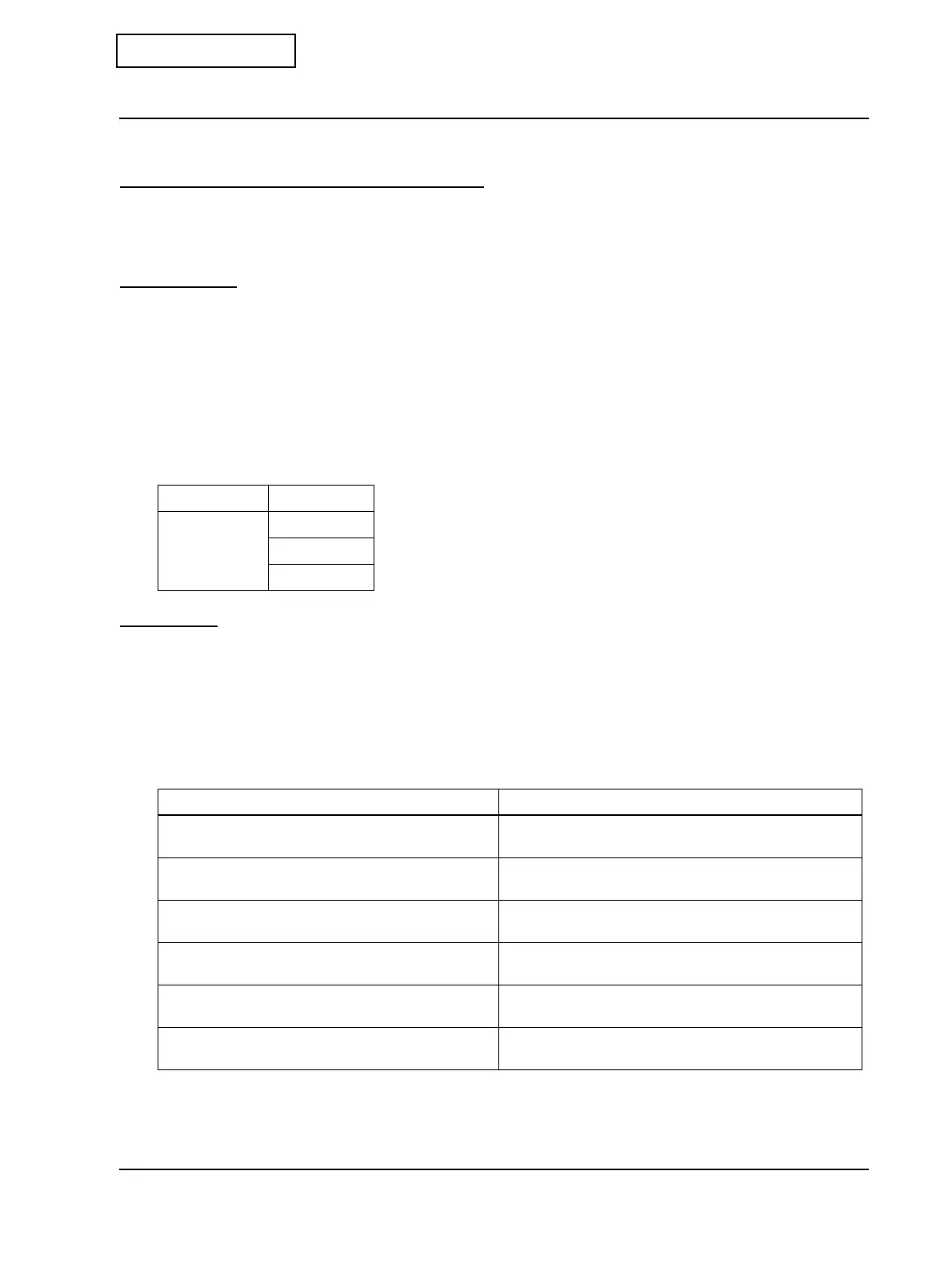

Table 5-2 Recommended cleaning

Checkpoints Cleaning method

Whether any dust or foreign material adheres to

thermal print head.

See “Cleaning the thermal head” section in this chapter.

Whether any paper dust or foreign material adheres

to LED holder assembly.

Remove the dust or foreign material with a cotton swab

lightly dampened with water.

Whether any paper dust or foreign material adheres

to BM paper detector circuit board assembly.

Remove the dust or foreign material with l a cotton swab

lightly dampened with water.

Whether any paper dust or foreign material adheres

to platen assembly.

Clean the platen with a cotton swab or cloth lightly

dampened with water.

Whether any paper dust or foreign material is present

on the cutter blade.

Wipe off with dry cloth or cotton swab.

Whether any paper dust, dirt, or foreign material

adheres to or is inside other parts.

Clean thoroughly using a small vacuum cleaner for

computer equipment.

Loading...

Loading...