Class II Biological Safety Cabinets

Cause Corrective Action

• If airflow sensor is working properly, Proceed to the next step.

B. Temperature Sensor Failure

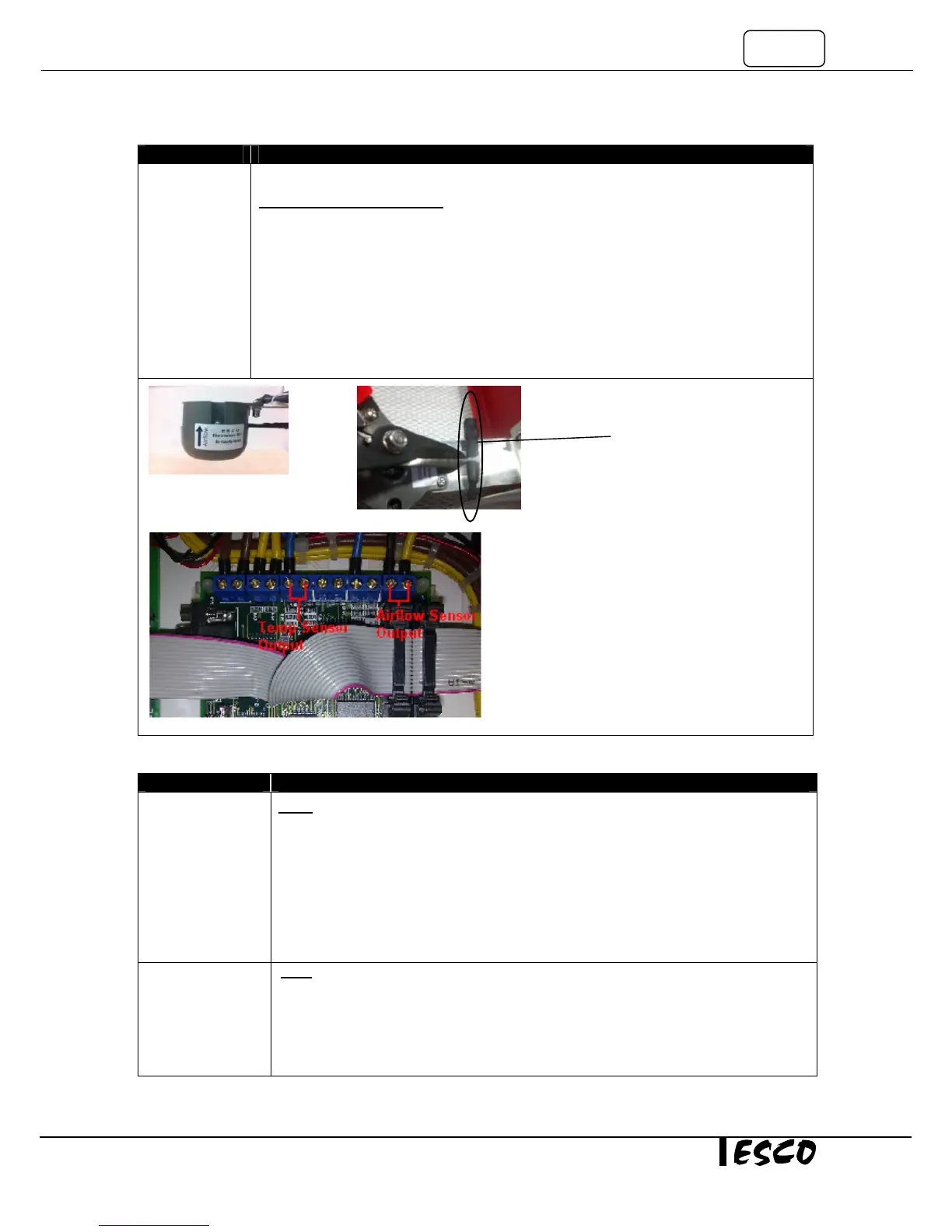

• Temperature sensor is located on top of the unit, close to exhaust airflow sensor. See

Figure 5-4.

• Using multimeter, check the temperature sensor’s output voltage (DC) at channel AIN4(-

) and J4(+) on main board See Figure 5-3.

• 0.01VDC should represent one degree Celsius. For example, if output is 0.25 VDC, it

indicates temperature of 25

o

C. Tolerance of ±1

o

C is acceptable.

• Replace temperature sensor if the reading is wrong.

• If temperature sensor is working properly, Proceed to the next step.

Problem 6: Excessive Blower Noise

Resonance Note: Requires a Certifier or qualified personnel

• Locate the motor speed controller.

• Measure the motor voltage and record this number

• Increase the motor speed by 5 – 10 VAC. Does the noise change or go away?

• If the noise is gone, measure the actual airflow velocity. Requires a Certifier

o If the velocity is still in the acceptable range, maintain it.

o If velocity is out of acceptable range, or if noise persists, go to next step.

Loose motor or

impeller wheel

mounting

Decontaminate cabinet first before accessing the blower

• Open the blower access panel and check if the blower mounting bolts are tight

• Does the motor rotate freely without noise?

• If motor is physically damaged, replace it.

Figure 5-5

Temperature

Loading...

Loading...