Class II Biological Safety Cabinets

Problem 9: Electrical socket always OFF

Cause Corrective Action

Connection

Problem

• Is the OUTLET LED Illuminated? If not press the Outlet button at the keypad

membrane in front panel.

• Check voltage coming to the Relay board.

• Locate LS4 (J6 Terminal) circuit and measure AC voltage between Large BLUE

(Neutral) terminal block and the end terminal (with Red cable-COM) on the three

terminal strip (J6).

• If there is voltage to the end terminal (with Red cable-COM), check the central

terminal (Normally Open circuit) to the BLUE (Neutral) terminal block.

• No voltage at the central terminal (Normally Open circuit) indicates a blown fuse or

the circuit is not energized.

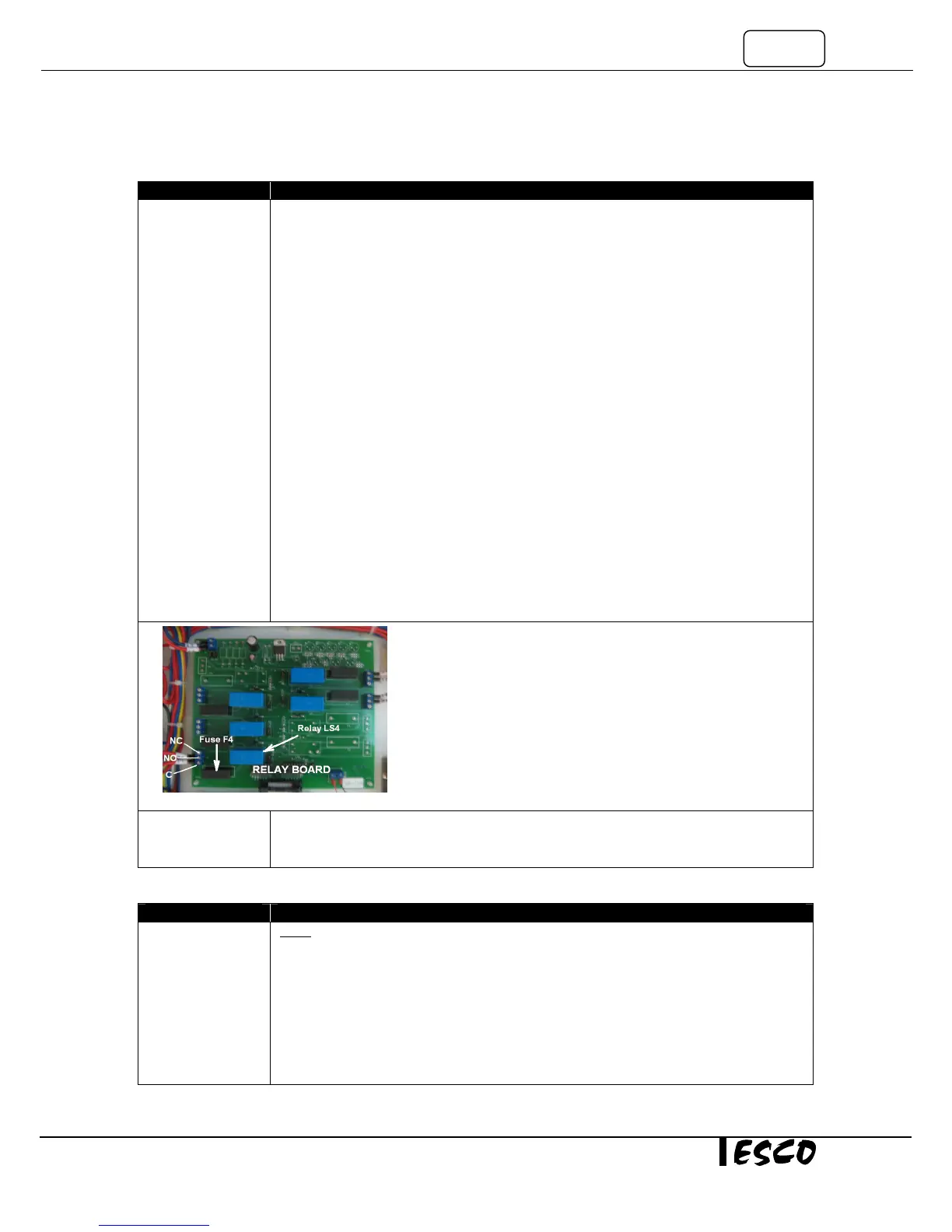

• Check Fuse F4 on relay board. See Figure 9-1 below.

• If fuse F4 is blown, replace with F5 fuse.

• If fuse F4 is OK, check the voltage between the BLUE (NEUTRAL) terminal block and

the end terminal (COM) on the LS4 circuit (J6 on relay board).

• Voltage at the end terminal (Normally Closed circuit) with no cable indicates the F4

fuse is good and the circuit is not energized. Make sure the OUTLET LED is on.

• If there is power to the relay and it is energized Check voltage across Connector B pin

1 to 2 and pin 4 to 5.

• If there is power through Connector B pins, remove socket outlets from wall.

• Check incoming power to the plug in the cable to the outlet

• No power indicates a wiring issue. Recheck voltage from Connector B pins.

• Check for loose or faulty connection between the power cord, IEC inlet and

Faulty electrical

socket

• Socket(s) is(are) located inside the work zone.

• Check electrical socket connection.

• If connection is correct but socket has no output, replace electrical socket.

Problem 10: Contaminated Sample/Lab

Cause Corrective Action

Blocked air grille/

Cabinet overloaded

with too many

items

Contaminated samples are normally the result of any of the following:

-Poor Technique of the user or lack of training.

-Samples being contaminated in the incubator or somewhere other than the BSC.

Items to check on the BSC:

• Make sure that the front and back air grilles are not blocked.

• Remove all equipment and other items from the cabinet and surface decontaminate

the cabinet including the area under the work surface.

• Surface decontaminate everything that is returned to the BSC.

• If the contamination problem persists, recertify the cabinet.

Loading...

Loading...