ESS XT-3 OWNER’S MANUAL

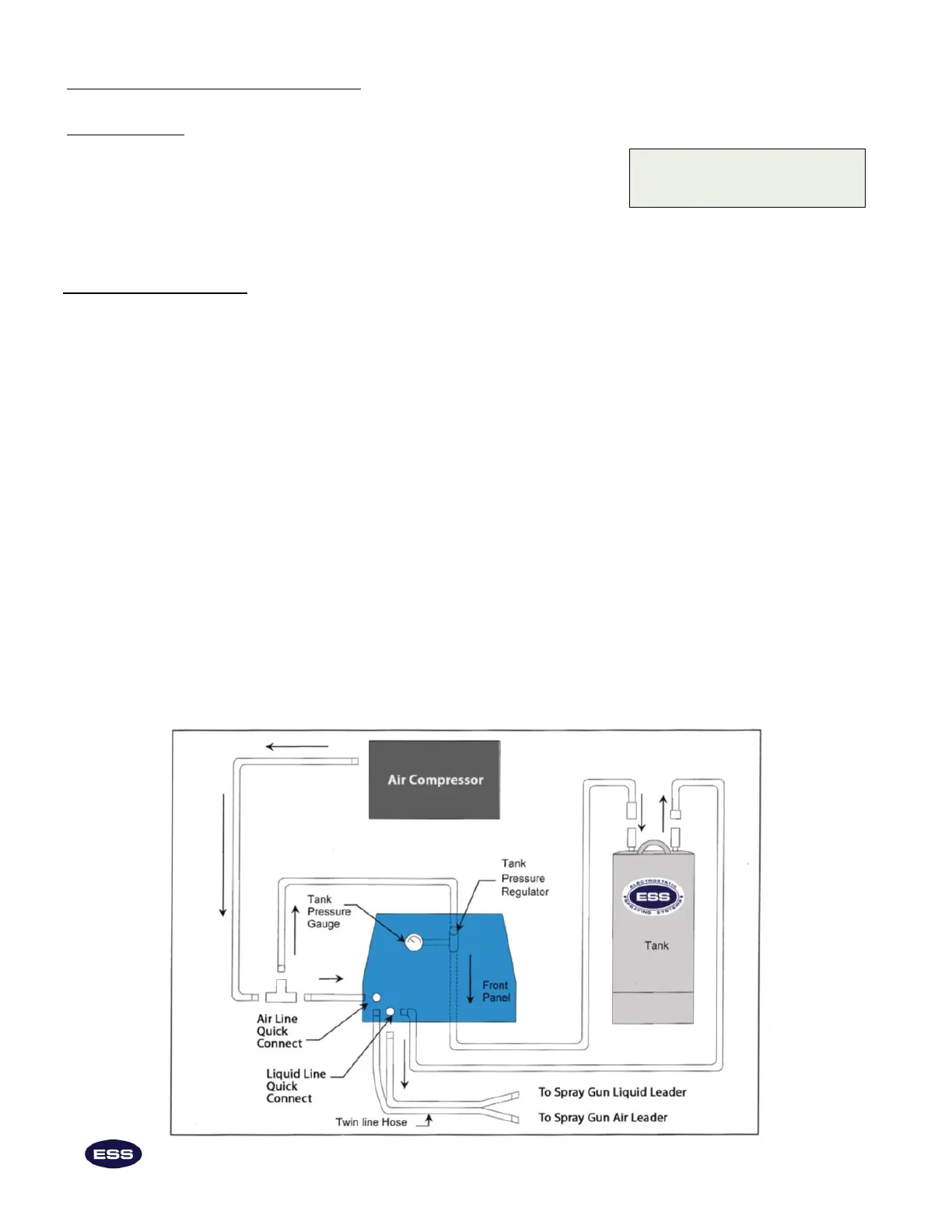

The Air & Liquid Delivery System

Air compressor

The air compressor produces compressed air which atomizes and propels

the liquid. It plugs into a 110 volt electrical source. Use the XT-3™ with a

three-pronged extension cord of no more than 50 feet and rated for no less

than 15 amp service. The On/O switch is on the side of the air compressor.

The XT-3 is also available with a

220-volt compressor.

14

Tank pressure regulator

As of January 1, 2010, the XT model no longer has a regulator and gauge. If you

have a model aer that date, you can no longer regulate the tank pressure.

Once you turn the sprayer on, the tank will ll with pressure and the sprayer will

funcon as it did before. If you have a model before, see the paragraph below.

There is a pressure regulator to control air pressure to the tank. It corresponds with the pressure gauge on the

le side of the front panel. This regulator is operated by pulling out the dial and turning it clockwise to

increase pressure or counter-clockwise to decrease pressure in the tank. This regulator controls the air

pressure going to the tank not to the spraygun. Generally tank pressure should be 15 psi. There are two

purposes for the tank pressurizaon: rst, to push the liquid soluon from the tank to the spraygun, and

second, to agitate the liquid in the tank, so that the chemical stays in soluon. Once the desired pressure is

achieved, push in the dial to lock it in place. Some chemicals have a tendency to foam. If you see any foam

coming out the pressure release tank value, either reduce the tank air pressure or add an “anfoaming” agent to

the soluon. In some occasions, it may be necessary to lower tank pressure to avoid foaming, to even as low as

5 psi. When adjusng tank pressure, one should dial pressure up to desired seng, rather than down. Two air

lines run from the tank pressure regulator. One line runs to the tank pressure gauge on the front panel. The

other runs to the inlet quick connect on the tank.

Loading...

Loading...