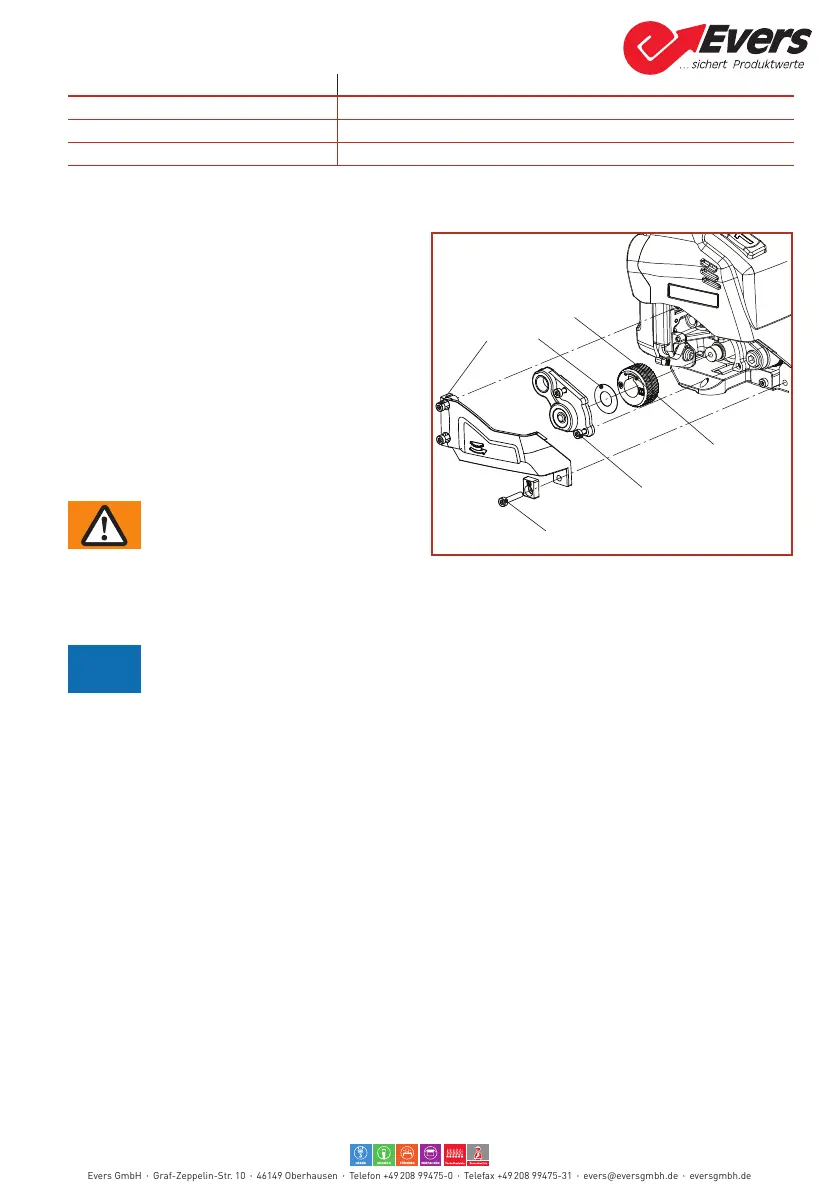

6.4 Cleaning/replacing the tension wheel

Required parts Order number

Tension wheel (3)* 1821.040.017

Shim disk (2) 1917.411.145

Cylinder screw Torx M4x20 (6) 1913.904.204

* Wear part

Dismantling

► Remove battery from tool.

► Loosen two cylinder head screws (1).

► Loosen cylinder head screw Torx (6) and

remove side cover and strap guide.

► Loosen two cylinder head screw (5) and ca-

refullypullthesupportplateotheexpansion

shaft.

► Carefully pull out the shim disk (2) and the

tension wheel (3).

– The rear shim remains on the expansion

shaft.

WARNING

Wear eye protection when cleaning

with compressed air!

► Clean tension wheel (3) with compressed air.

► In the case of heavy soiling of the toothing: Carefully clean tension wheel with wire brush.

► Check tension wheel for worn teeth. If teeth are worn, replace tension wheel.

Attention

The tension wheel must not be cleaned while it is rotating. Risk of tooth breakage!

Fitting

► Fitting is performed in reverse order. Observe the installation direction of the tension wheel, see

arrow (4) on the outside of the tension wheel.

► Lightly lubricate the inner diameter of the tension wheel with universal grease (e.g. Klüber grease

GBU Y 131, Microlube).

!

1

2

6

3

5

4

Evers GmbH Graf-Zeppelin-Str. 10 46149 Oberhausen Telefon +49 208 99475-0 Telefax +49 208 99475-31 evers@eversgmbh.de eversgmbh.de

Loading...

Loading...