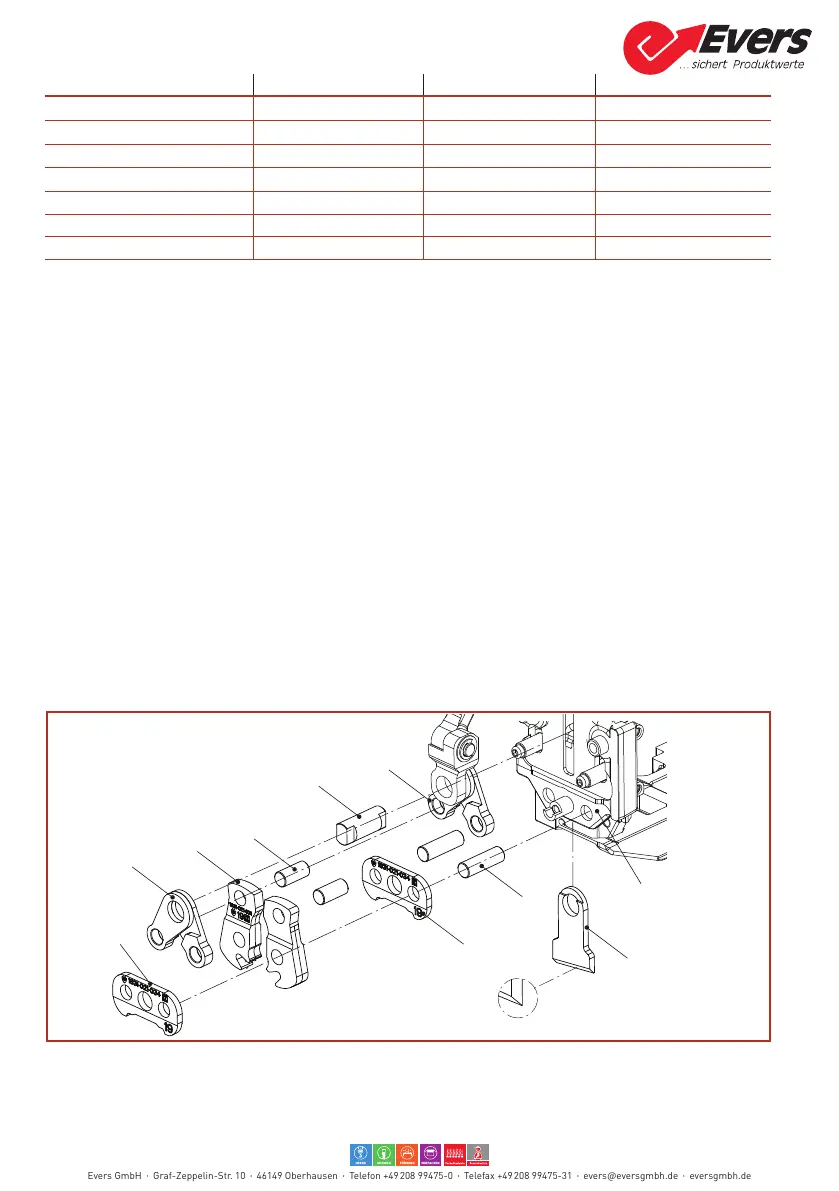

6.5 Cleaning/replacing jaws, notcher and cutter

Required parts Order no.13 mm (

1

/

2

″) Order no. 16 mm (

5

/

8

″) Order no. 19 mm (

3

/

4

″)

Jaw (3)* 1831.021.029 1831.021.030 1831.021.031

Notcher (1) (10)* 1831.021.032 1831.021.033 1831.021.034

Cutter (8)* 1821.208.018 ʺ ʺ

Jaw actuator (2) (6) 1831.021.112 ʺ ʺ

Jaw pin (4) 1831.021.039 ʺ ʺ

Jaw axle (9) 1831.021.037 ʺ ʺ

Guidance bolt (5) 1831.021.035 ʺ ʺ

* Wear part

Dismantling

► Remove battery from tool.

► Remove front covers (Section 6.3).

– The jaw mechanism, which is only held in position by grease, is now open.

► Remove two jaw actuators (2) and pull out jaw pins (4).

► Remove notcher (1), jaws (3) and rear notcher (10) and pull out jaw axles (9).

► Pull out the guidance bolt (5) and remove the rear jaw actuator (6) and the cutter (8) mounted

behind the jaw carrier (7) downwards.

► Clean notchers (1 and 10), jaws (3) and cutter (8), check for wear and replace if necessary.The

notcher (1 and 10) can also be turned 180° to use the second cutting edge.

Fitting

► Lubricate the cleaned or replaced parts at the joints and sliding points with universal grease (e.g.

Klüber GBU Y 131, Microlube).

► Bring cutter (8) behind jaw carrier (7) into mounting position, and the rear jaw actuator (6) into

positioninfrontofjawcarrierandxwithguidancebolt(5).Pushtheguidanceboltforwardasfar

as it will go and align the milled surfaces vertically as shown in the drawing.

► Fitting is performed in reverse order.

1

6

2

3

4

5

10

9

8

7

Evers GmbH Graf-Zeppelin-Str. 10 46149 Oberhausen Telefon +49 208 99475-0 Telefax +49 208 99475-31 evers@eversgmbh.de eversgmbh.de

Loading...

Loading...