145

ELECTRICAL AND IGNITION

ELECTRIC STARTER SERVICING

7

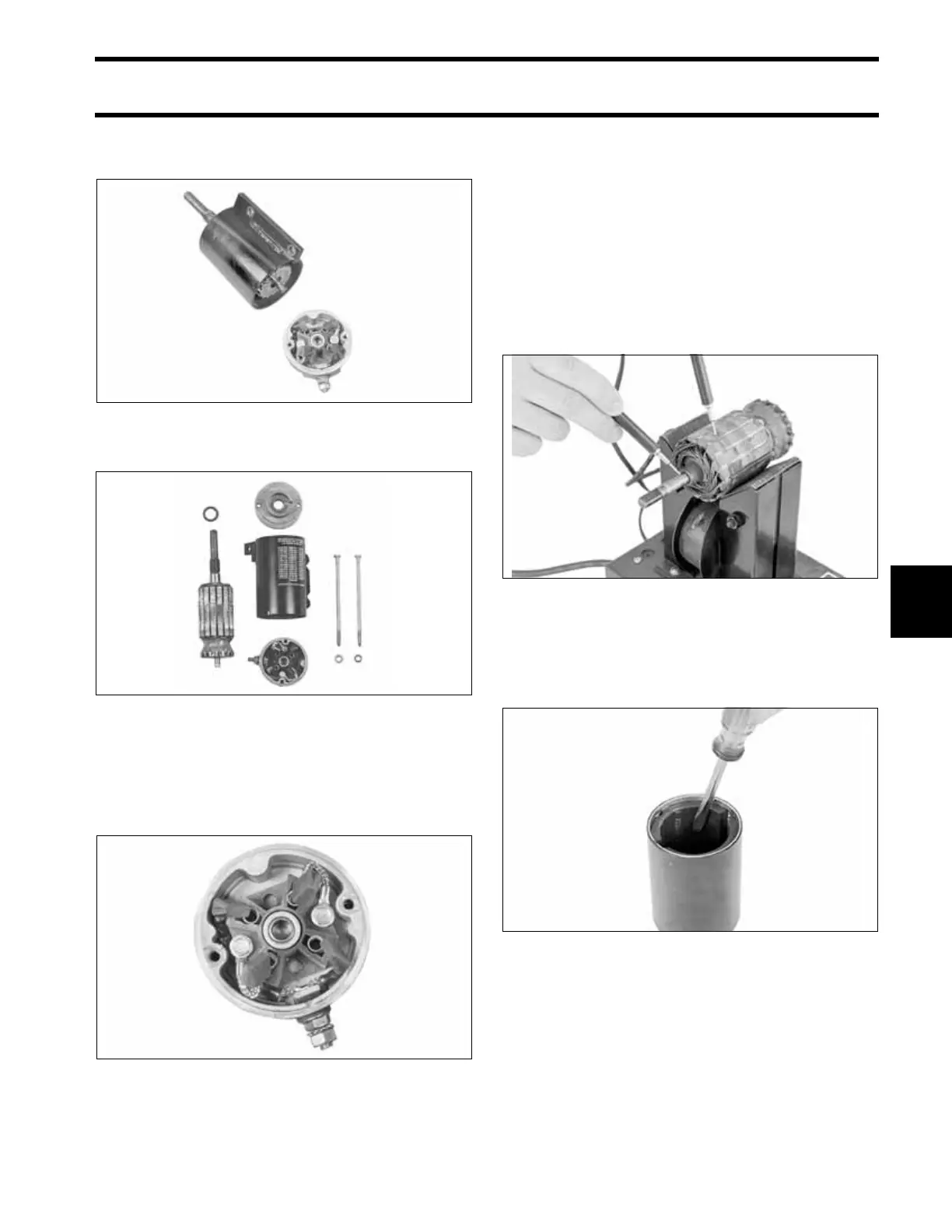

Remove brush holder cap from armature and

frame assembly. Do not lose the brush springs.

Slowly, remove the armature from frame.

Starter Cleaning and Inspection

Inspect the brushes for wear and damage.

Replace brushes if damaged or worn. Replace

weak brush springs.

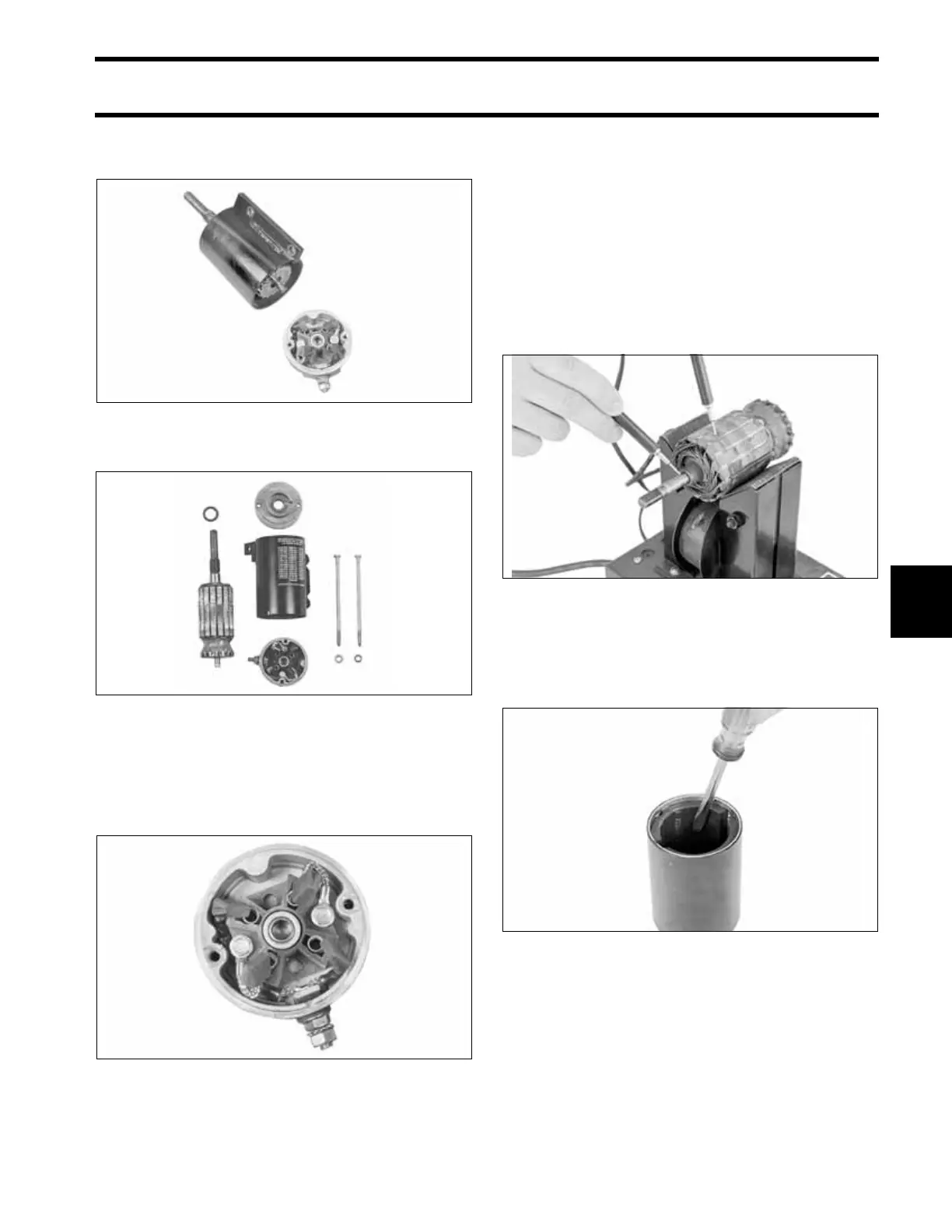

Clean the commutator with 300-grade emery

cloth. If commutator surface is unevenly worn or

pitted, turn it on a lathe. Remove any trace of oil or

metal dust from commutator.

Check the armature on a growler for shorted turns

using a test light or meter. Inspect armature insu-

lation for indications of overheating or damaged

windings. Clean off any carbon deposits or foreign

matter which could contribute to failure of wind-

ings.

Check permanent magnets and make sure they

strongly attract any steel or iron object held inside

frame. Weak magnetism could cause excessive

RPM on No Load Current Draw Test on p. 132.

After disassembling the drive, clean each part with

Cleaning Solvent and inspect for wear and distor-

tion.

002299

38288

002300

TYPICAL 24058

TYPICAL 24057

Loading...

Loading...