33

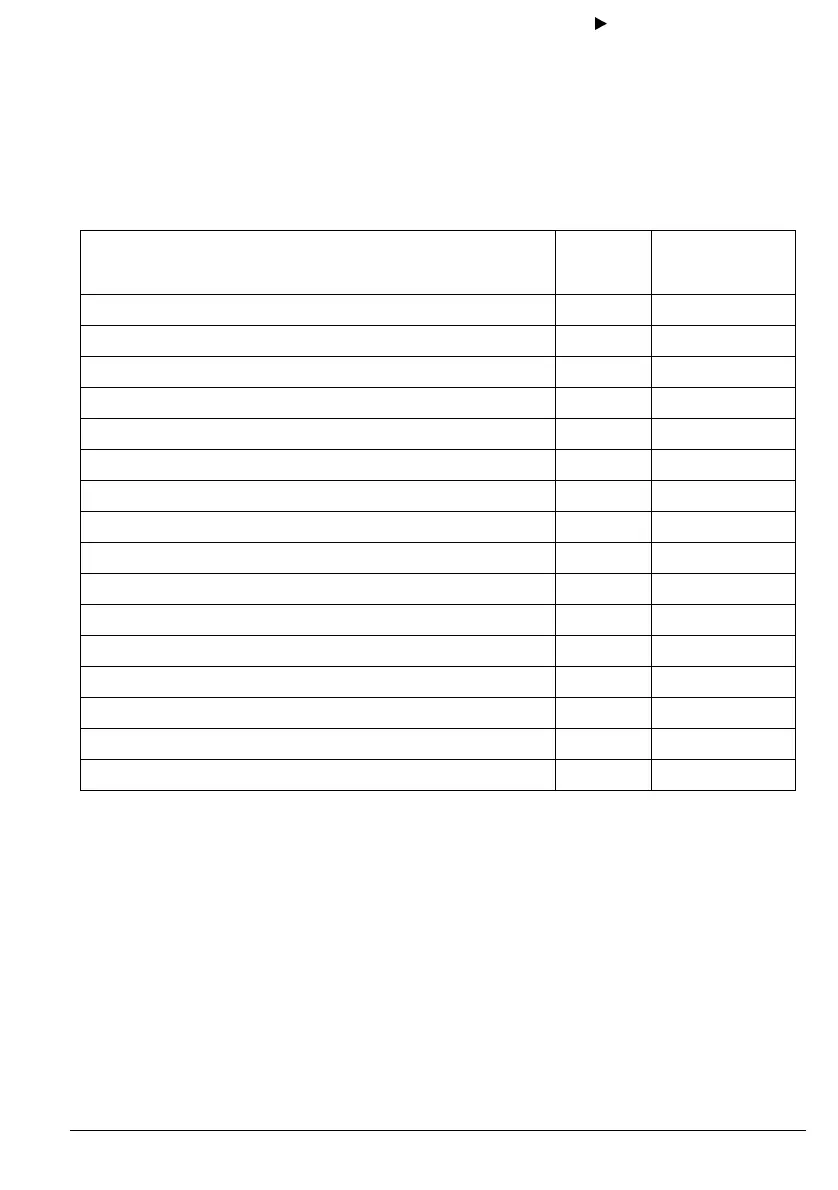

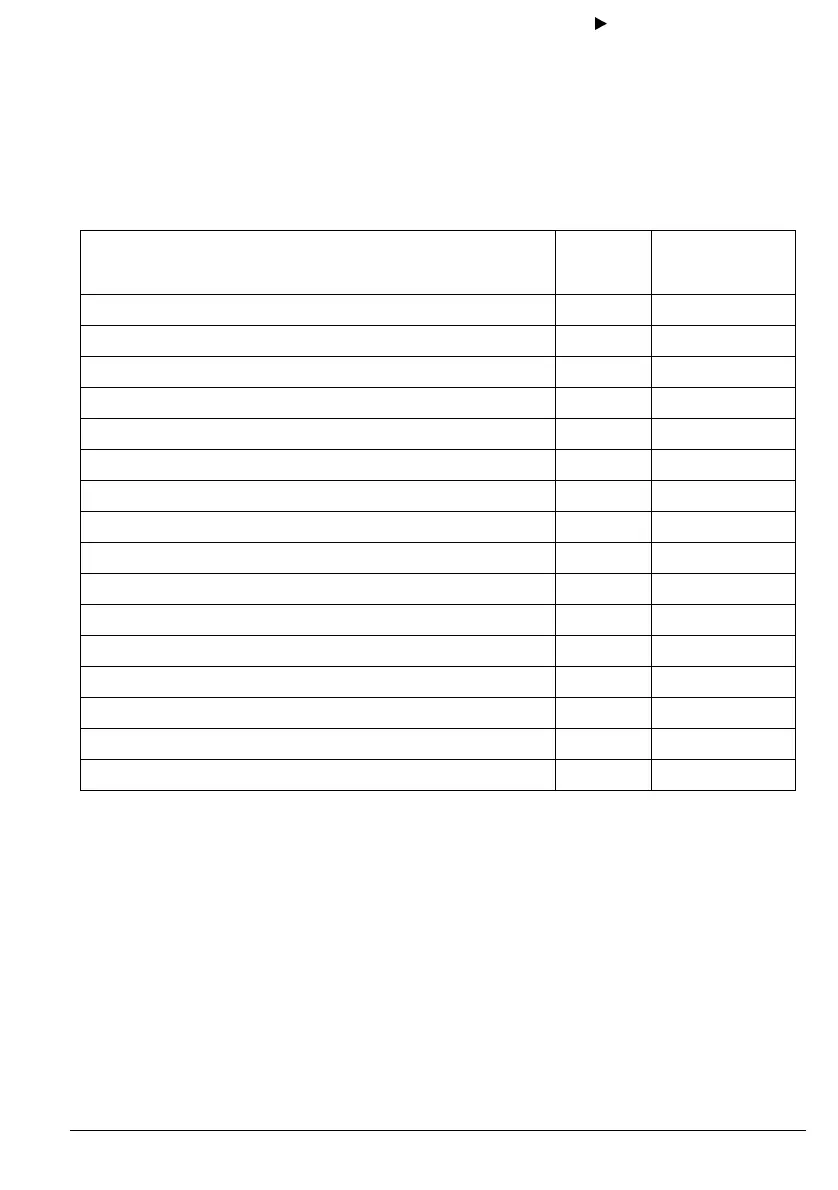

MAINTENANCE SCHEDULE

MAINTENANCE SCHEDULE

Routine maintenance is necessary for all mechanized products. Periodic maintenance contrib-

utes to the product’s life span. The following maintenance chart provides guidelines for out-

board maintenance and inspection scheduled to be performed by an authorized Dealer. The

schedule should be adjusted according to operating conditions and use.

The recommended lubricants have been formulated to protect bearings, gears and engine

components. They must be used to avoid damage caused by improper lubrication.

Description

Engine

Care

Product

Every 300

Hours or

Three Years

(1)

(1) When used in normal recreational use. Common sense dictates when using an Evinrude E-TEC

outboard for commercial or other heavy use that you check these items more frequently (annual

checks are recommended).

Electrical and ignition wires, inspect for wear or chafing

Engine to transom mounting hardware, re-torque (40 ft. lbs.)

Fasteners, inspect any loosened components

Fuel and oil system components, inspect and repair leaks

(2)

(2) Emission-related component

Fuel filter, replace

Gearcase lubricant, replace

A

Grease fittings, lubricate

(3)

(3) Annually in salt water applications – Refer to Salt Water Lubrication Points on page 28

Muffler foam, inspect and replace if necessary

Power trim/tilt system and fluid level, inspect

B

Propeller shaft splines, inspect and lubricate

(3)

C

Spark plugs, inspect and replace if necessary

(2)

Starter pinion shaft, inspect and lubricate

D

Steering system, inspect and lubricate

C

Thermostats, inspect

(2)

Throttle cable, inspect and re-tension

Water pump, inspect or replace if necessary

A.

Ultra-HPF

gearcase lubricant

B. Power Trim/Tilt Fluid

C.

Triple Guard

grease

D. Starter Bendix Lube Only P/N 337016

Loading...

Loading...