241

POWERHEAD

POWERHEAD INSTALLATION

11

Install flywheel. Refer to Flywheel Installation on

p. 110.

Install air temperature sensor, air silencer, and fly-

wheel cover. Tighten flywheel cover screws to a

torque of 30 to 42 in. lbs. (3.5 to 5 N·m).

Install the lower engine covers. Refer to LOWER

COVER SERVICE on p. 51.

Pre-Service Adjustments

After installing a new or rebuilt

powerhead, perform the following procedures

before returning outboard to service:

• Adjust timing pointer.

• Index all spark plugs. Refer to Spark Plug

Indexing on p. 40.

• Use Evinrude Diagnostics software to start pow-

erhead break-in oiling. Refer to Powerhead

Break-In on p. 67.

• Use Evinrude Diagnostics software to set TPS

calibration. Refer to TPS CALIBRATION on

p. 113.

• Use Evinrude Diagnostics software to make

sure engine management software version and

revision are current. Update as required.

• Prime fuel system.

• Prime oiling system. Refer to OIL SUPPLY

PRIMING on p. 170.

• Use Evinrude Diagnostics software to check

engine timing. Refer to TIMING ADJUST-

MENTS on p. 112.

• Run outboard and check for water, fuel, or oil

leaks.

• Make sure engine reaches correct operating

temperature and does not overheat.

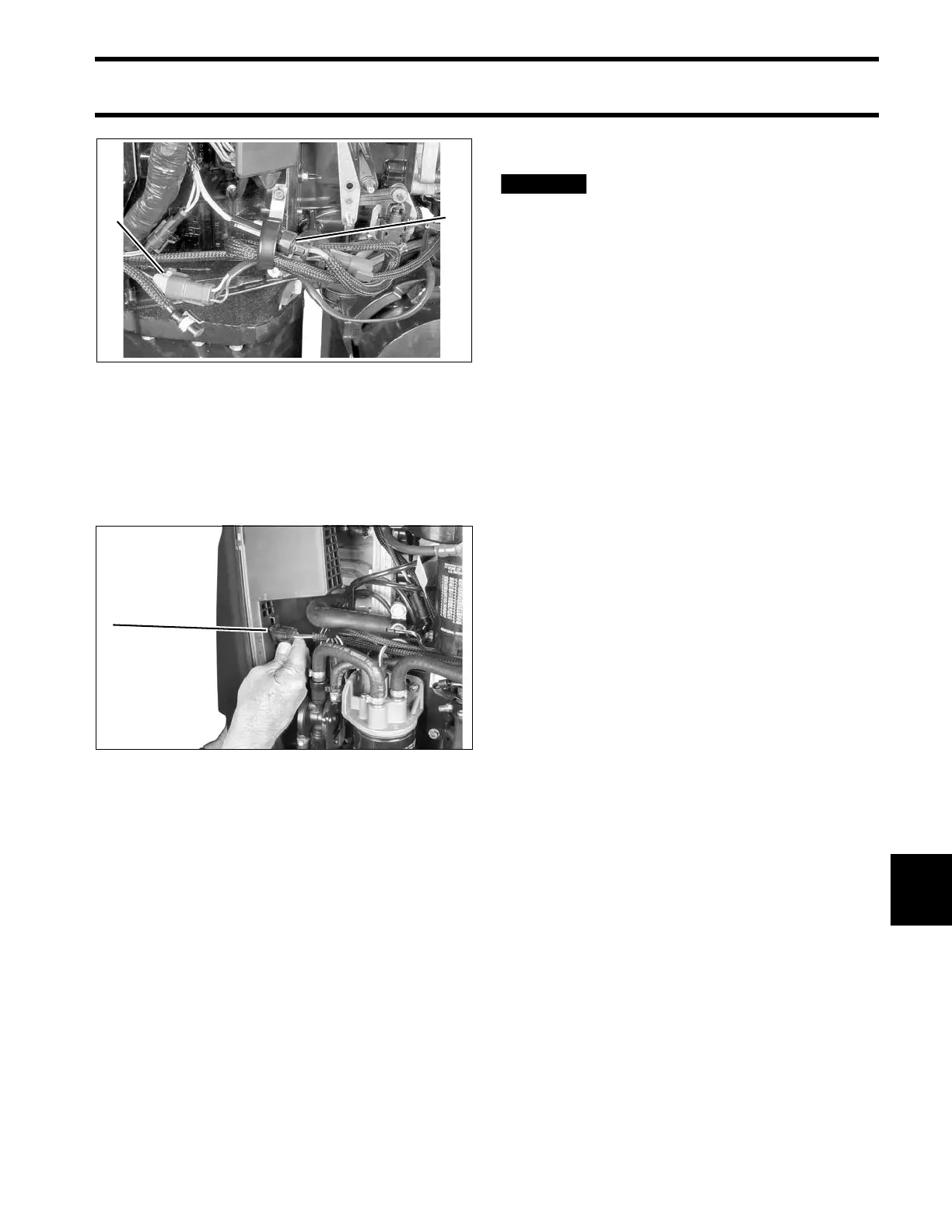

1. Trim/tilt connectors 004251

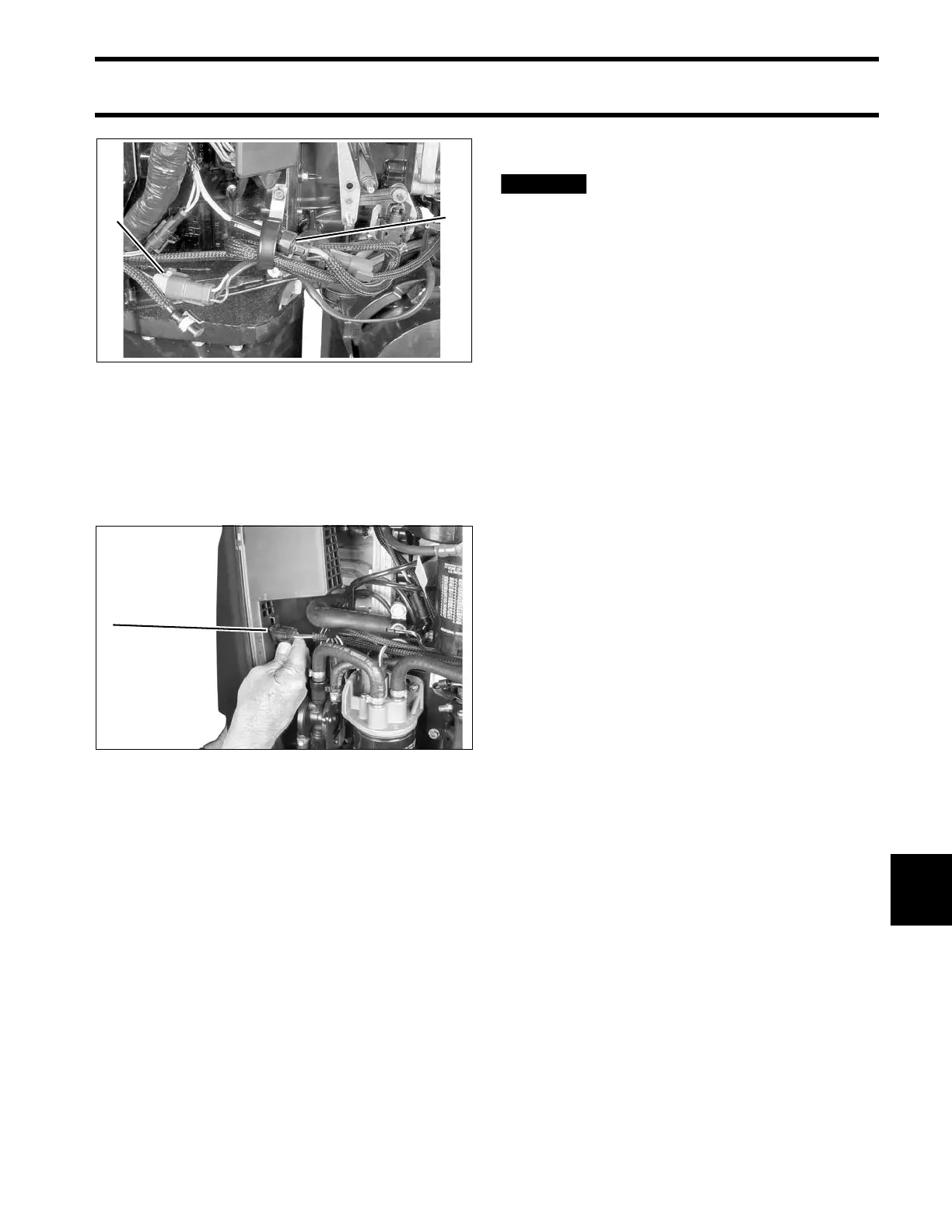

1. Air temperature sensor 004219

Loading...

Loading...