373

TRIM AND TILT

ELECTRICAL CIRCUIT TESTS

14

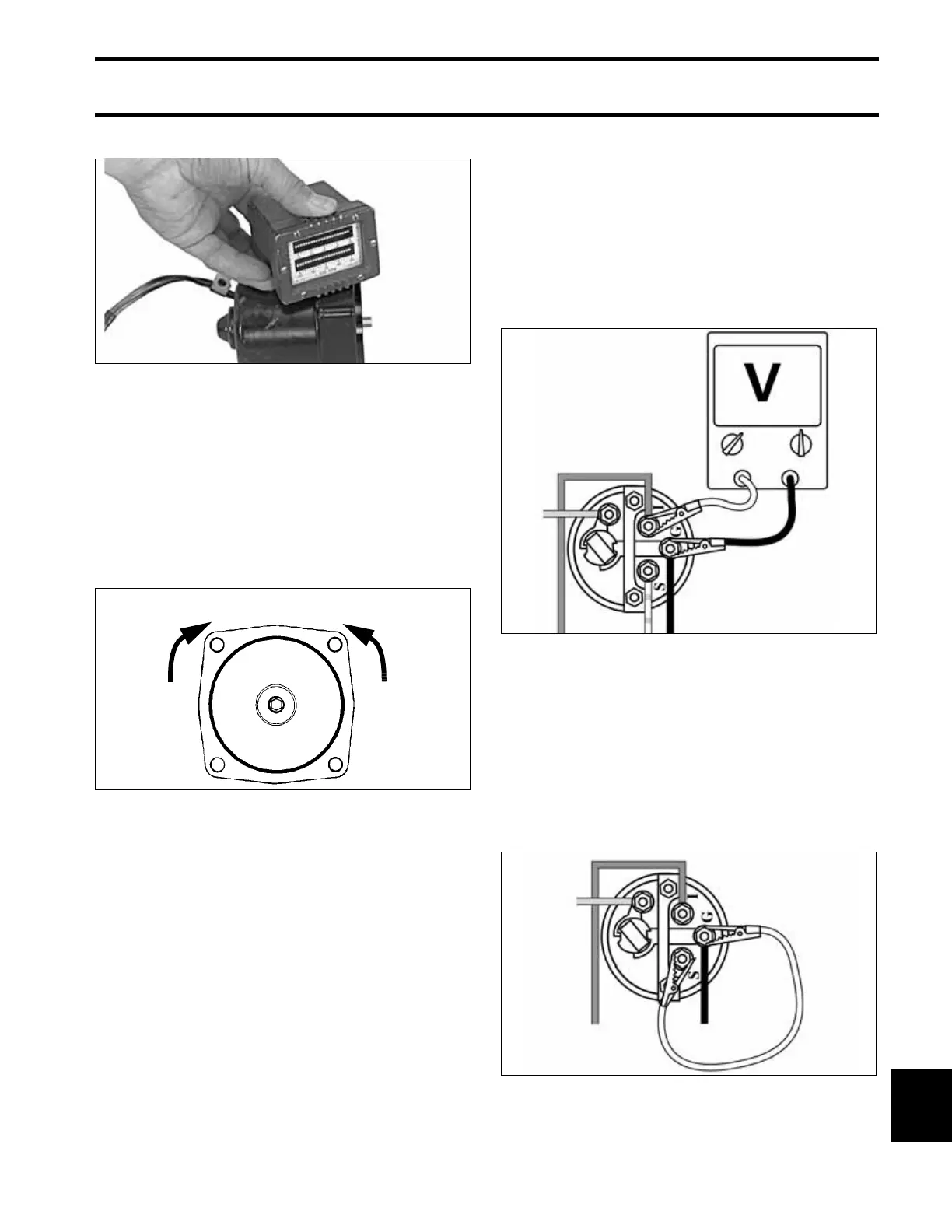

Monitor motor RPM and current draw.

The motor shaft must rotate clockwise, as viewed

from the pump end, when positive (+) is applied to

the blue lead, and negative (–) is connected to

green lead.

The motor shaft must rotate counterclockwise, as

viewed from the pump end, when positive (+) is

applied to the green lead, and negative (–) is

applied to the blue lead.

If test results vary, replace the motor.

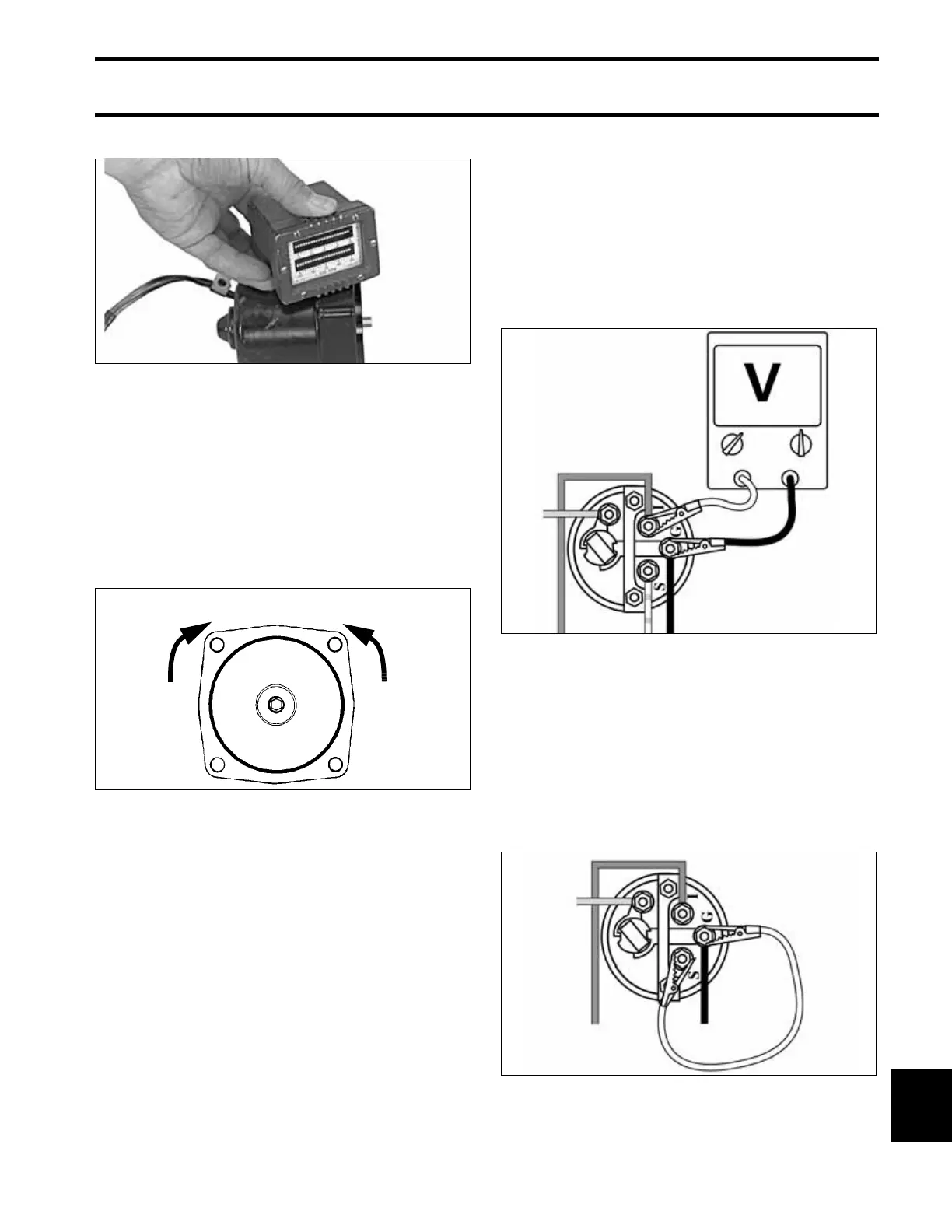

Trim Gauge Test

STEP 1

Turn key switch ON. Using a voltmeter, check for

voltage between the trim gauge “I” and “G” termi-

nals.

• If no voltage, check condition of instrument har-

ness, key switch, and engine 20 A fuse.

• If voltage, go to STEP 2.

STEP 2

Remove the white/tan lead from the trim gauge

“S” terminal. With key switch ON, gauge should

indicate full-trim DOWN position. Now connect a

jumper wire between terminals “S” and “G.”

Gauge should indicate full-trim UP position.

• If results are different, replace the trim gauge.

• If results agree, refer to Trim Sender Test.

30957

DR4238r

Green lead (+)

Blue lead (-)

Blue lead (+)

Green lead (-)

DRC6245

DRC6246A

Loading...

Loading...