Operation

AdjustingtheAnti-Scalp

Rollers

Itisrecommendedtochangetheanti-scalproller

positionwhentheheightofcuthaschanged.

1.Stopthemachineandreleasethetraction-control

pedaltoplacethemachineintheneutralposition.

2.DisengagethePTO.

3.Engagetheparkbrake.

4.Stoptheengine,removethekeyandwaitforall

movingpartstostop.

5.Afteradjustingtheheightofcut,adjustthe

anti-scalprollersbyremovingthenylocnut.

6.Adjusttheanti-scalprollersforthenormal

operatingconditions.Placerollersinoneofthe

positionsshowninFigure14orFigure15.Rollers

willmaintain3/4inches(19mm)clearanceto

thegroundtominimizegougingandrollerwear

ordamage.

Note:ForMaximumDeckFlotation,place

therollersoneholepositionlower.Rollersshould

maintain1/4inch(6.35mm)clearancetothe

ground.DoNotadjustrollerstosupportthe

deck.

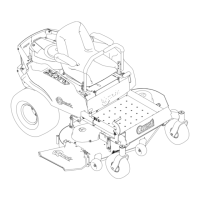

Figure14

42InchDeck

1.Anti-scalprollermountingbracket

2.Below21/2inches(64mm)cuttingheight

3.21/2inches(64mm)andabovecuttingheight

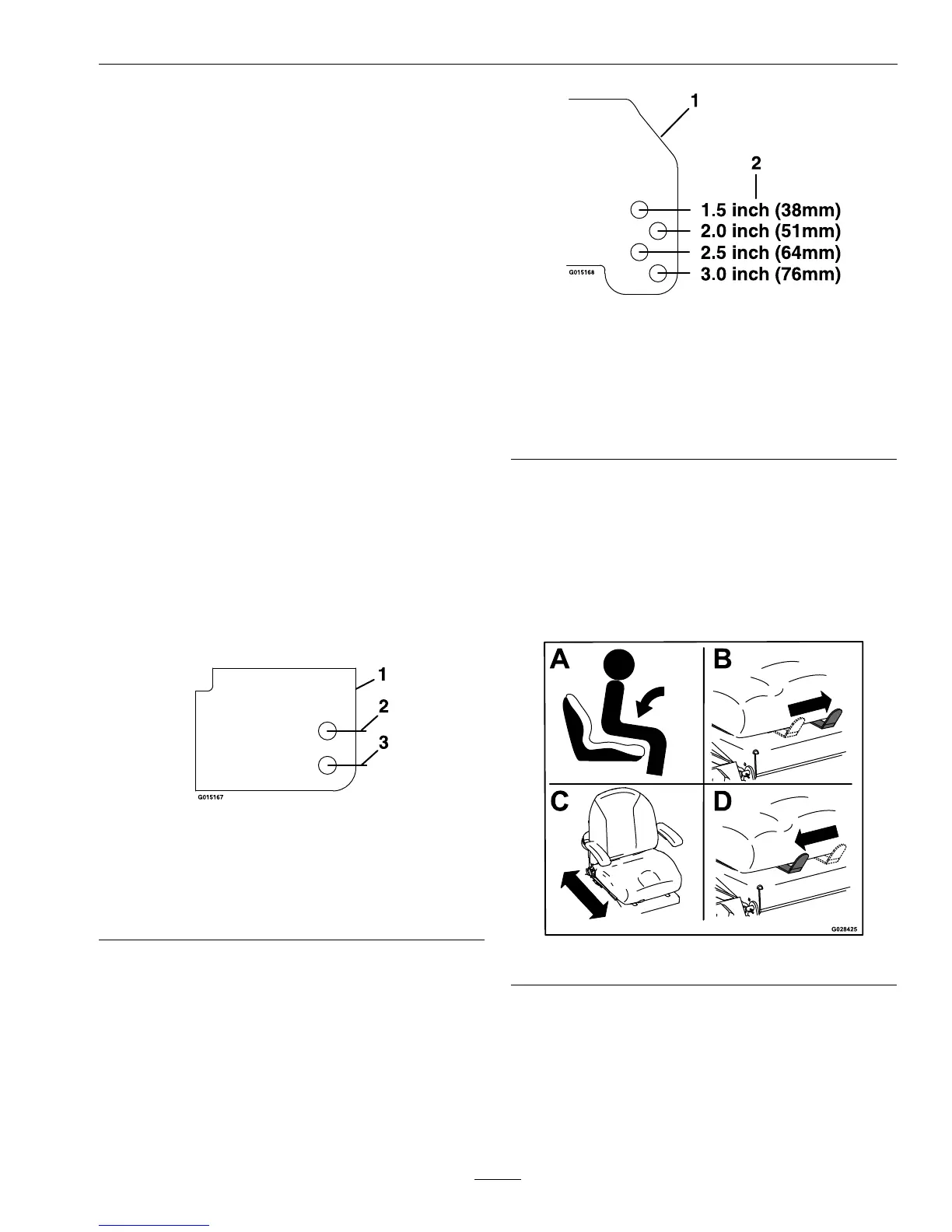

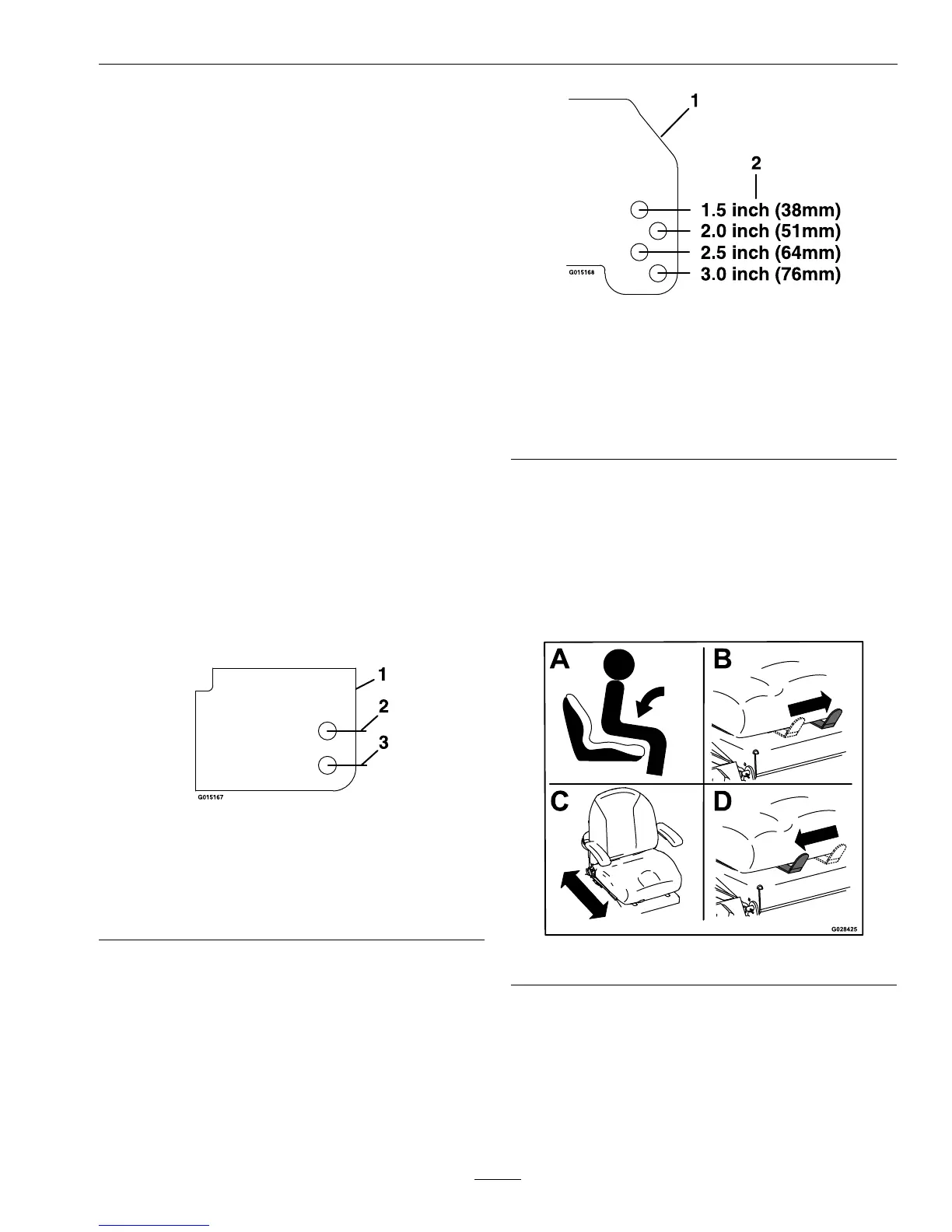

Figure15

50InchDeck

Forcuttingheightsabove31/2inches(90mm)

usethebottomhole.Therollerswillstillbeeffective

againstscalping.

1.Anti-scalproller

mountingbracket

2.Cuttingheight

7.Torquehardwareto27-33ft-lb(37-45N-m)or

lossofrollermayresult.

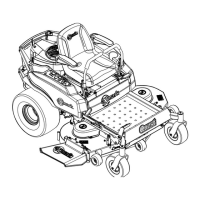

PositioningtheSeat

Theseatcanmoveforwardandbackward.Position

theseatwhereyouhavethebestcontrolofthe

machineandaremostcomfortable.

Figure16

ChangingtheSeatRide

Suspension

Thenumberofseatspringscanbechangedto

maximizeridercomfort.Morespringsshouldbeused

withheavieroperatorsandonroughterrain.Fewer

29

Loading...

Loading...