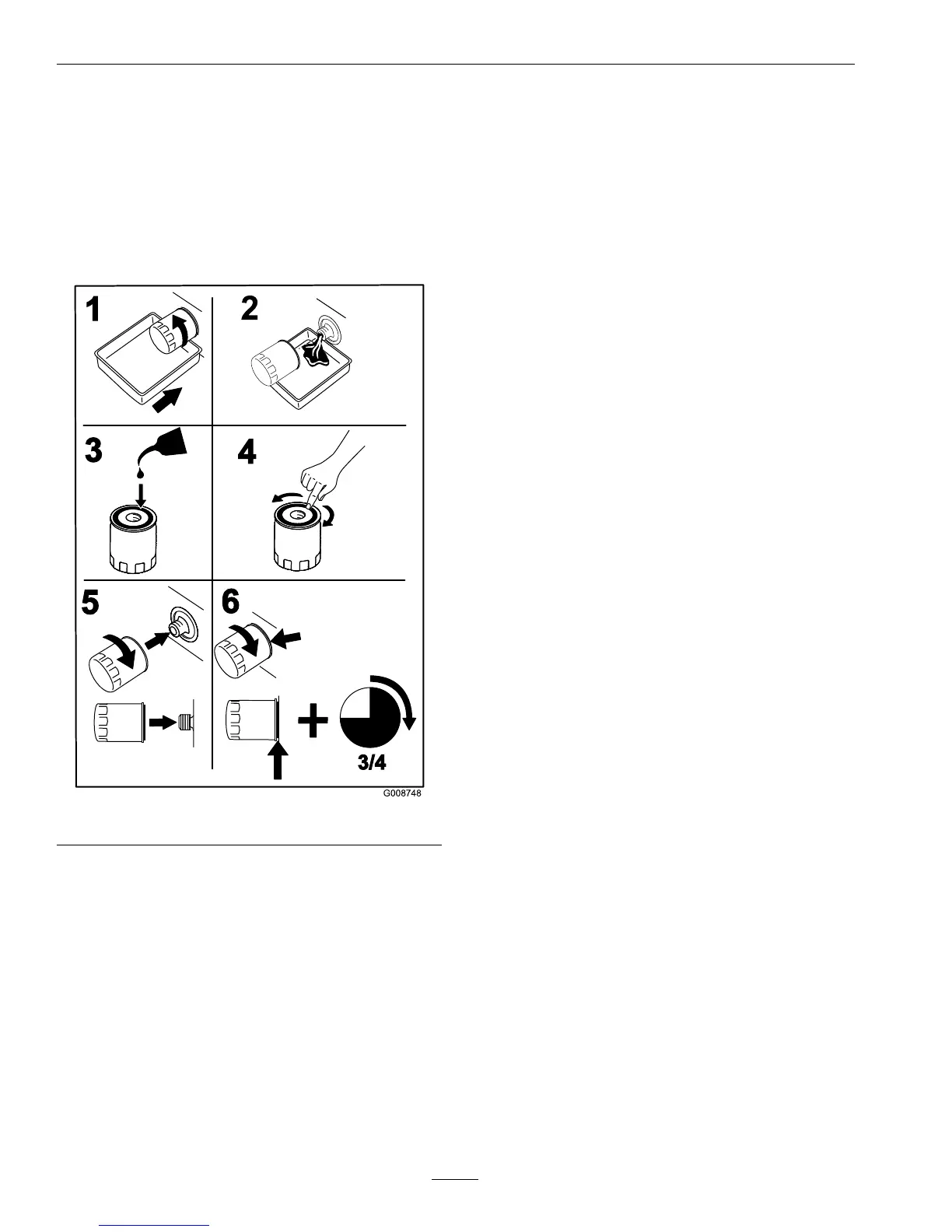

Figure57

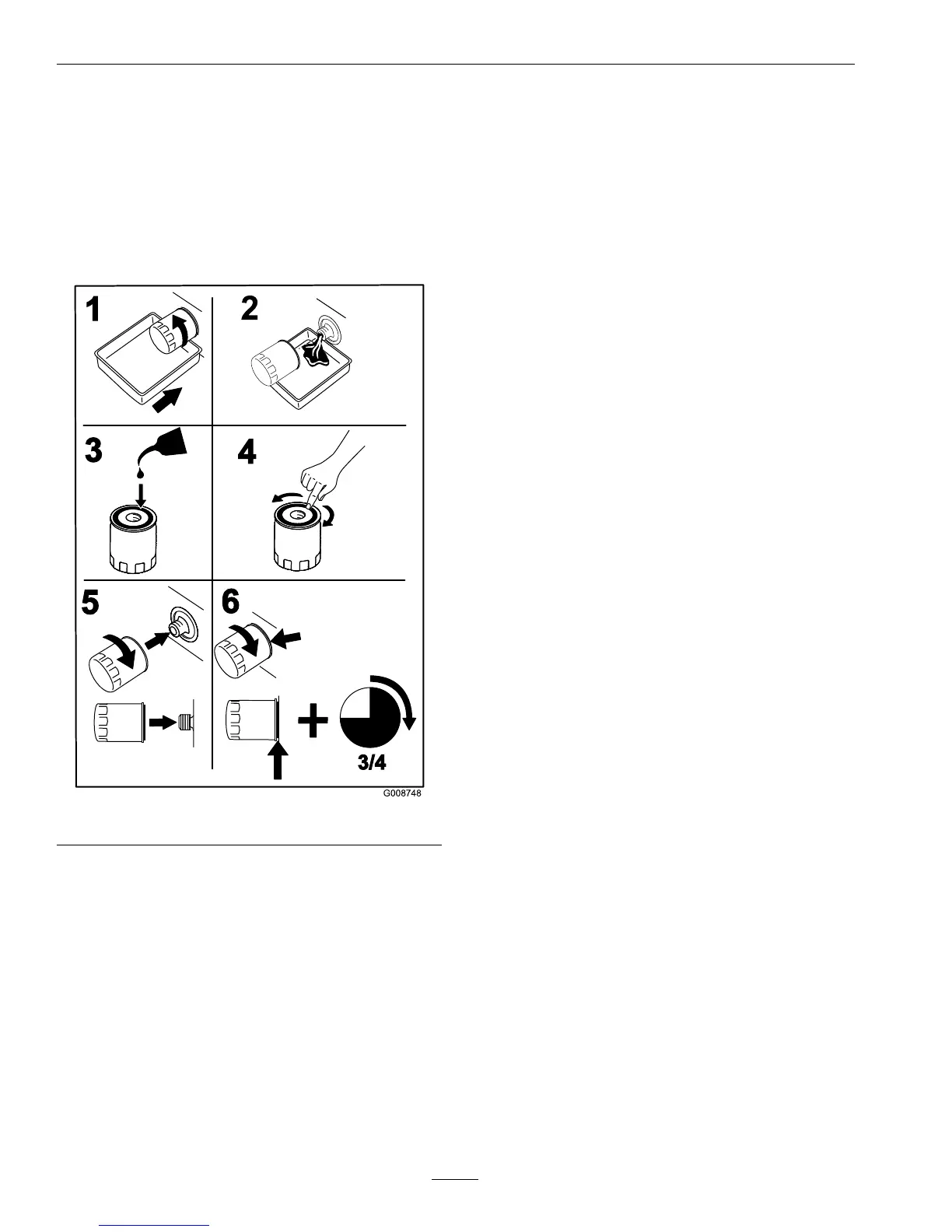

1.Applyathincoatofoilonthesurfaceofthe

rubbersealofeachlter.

2.Turnthelterclockwiseuntilrubbersealcontacts

thelteradapterthentightenthelteran

additional3/4to1fullturn.Repeatfortheother

lter

3.Installthelterguardsovereachlteras

previouslyremoved.Usethethreescrewsto

securethelterguards.

4.Verifytheventplugsareremovedbeforeadding

theoil.

5.Slowlypourthespeciedoilthroughexpansion

reservoiruntiloilcomesoutofoneofthevent

plugholes.Stopandinstallthatventplug.Torque

theplugto180in-lb(20.3N-m).

6.Continuetoaddoilthroughtheexpansion

reservoiruntiloilcomesoutoftheremaining

ventplugholeonthesecondtransmission.Stop

andinstallthatventplug.Torquetheplugto180

in-lb(20.3N-m).

7.Continuetoaddoilthroughtheexpansion

reservoiruntilitreachestheFULLCOLDlineon

theexpansionreservoir.

8.Installthetransaxleguard.

9.ProceedtotheBleedingtheHydraulicSystem

section.

Important:Failuretoperformthe

Bleeding

the Hy draulic System

procedureafter

changinghydraulicltersandoilcanresult

inirreparabledamagetothetransaxledrive

system.

BleedingtheHydraulicSystem

1.Entertheoperator'sposition.Startengineand

movethrottlecontrolaheadto1/2throttle

position.Disengageparkingbrake.

A.Movethebypassleversintothepushing

themachineposition;refertoPushingthe

MachinebyHandsectioninOperation.

Withthebypassvalvesopenandtheengine

running,slowlymovethetraction-control

pedalinbothforwardandreverse(5or6

times).

B.Movethebypassleversintotheoperating

themachineposition.Withthebypassvalve

closedandtheenginerunning,slowlymove

thetraction-controlpedalinbothforwardand

reversedirections(5to6times).

C.Stoptheengineandchecktheoillevelinthe

expansionreservoir.Addthespeciedoil

asuntilitreachestheFullColdlineonthe

expansionreservoir.

2.Repeatstep1untilalltheairiscompletelypurged

fromthesystem.

Whenthetransaxleoperatesatnormalnoise

levelsandmovessmoothlyforwardandreverseat

normalspeeds,thenthetransaxleisconsidered

purged.

3.Checktheoillevelintheexpansionreservoirone

lasttime.Addthespeciedoiluntilitreaches

54

Loading...

Loading...