Maintenance

ServicingtheFuses

ServiceInterval:Asrequired

Theelectricalsystemisprotectedbyfuses.Itrequires

nomaintenance;however,ifafuseblows,checkthe

component/circuitforamalfunctionorshort.

Fuse:

•MainF1-30amp,blade-type

•ChargeCircuitF2-25amp,blade-type

1.Removethefourscrewssecuringthecontrol

paneltothemachine.Retainallfasteners

2.Liftthecontrolpaneuptoaccessthemainwiring

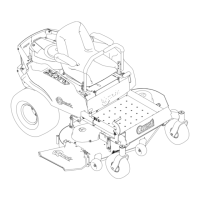

harnessandfuseblock(Figure51).

3.Toreplaceafuse,pulloutonthefusetoremove

it(Figure51).

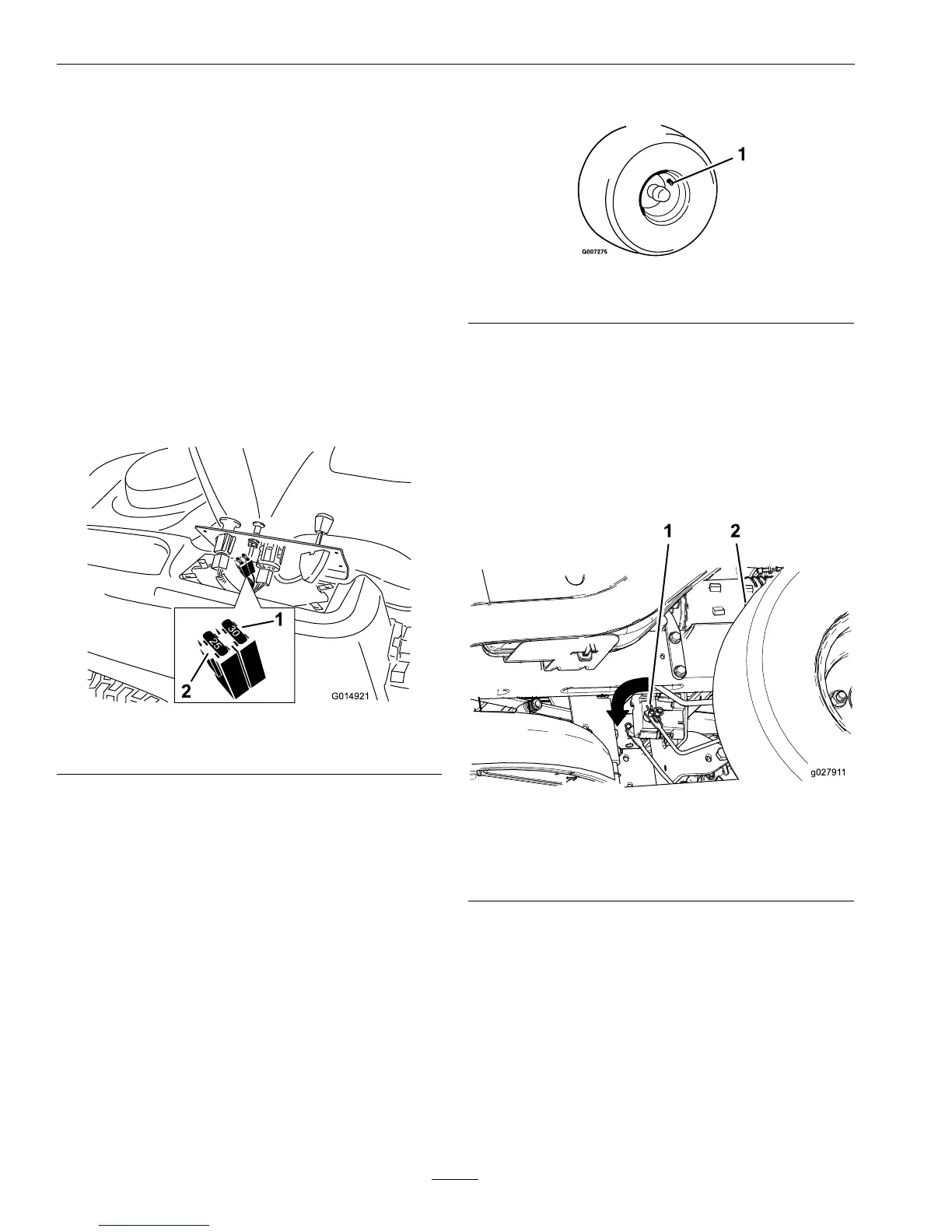

Figure51

1.Main-30amp

2.Chargecircuit-25amp

4.Returnthecontrolpaneltoitsoriginalposition.

Usethefourscrewsremovedpreviouslytosecure

thepaneltothemachine.

DriveSystemMaintenance

CheckingtheTirePressure

ServiceInterval:Every25hours/Monthly

(whichevercomesrst)

Maintaintheairpressureinthefrontandreartiresas

specied.Uneventirepressurecancauseunevencut.

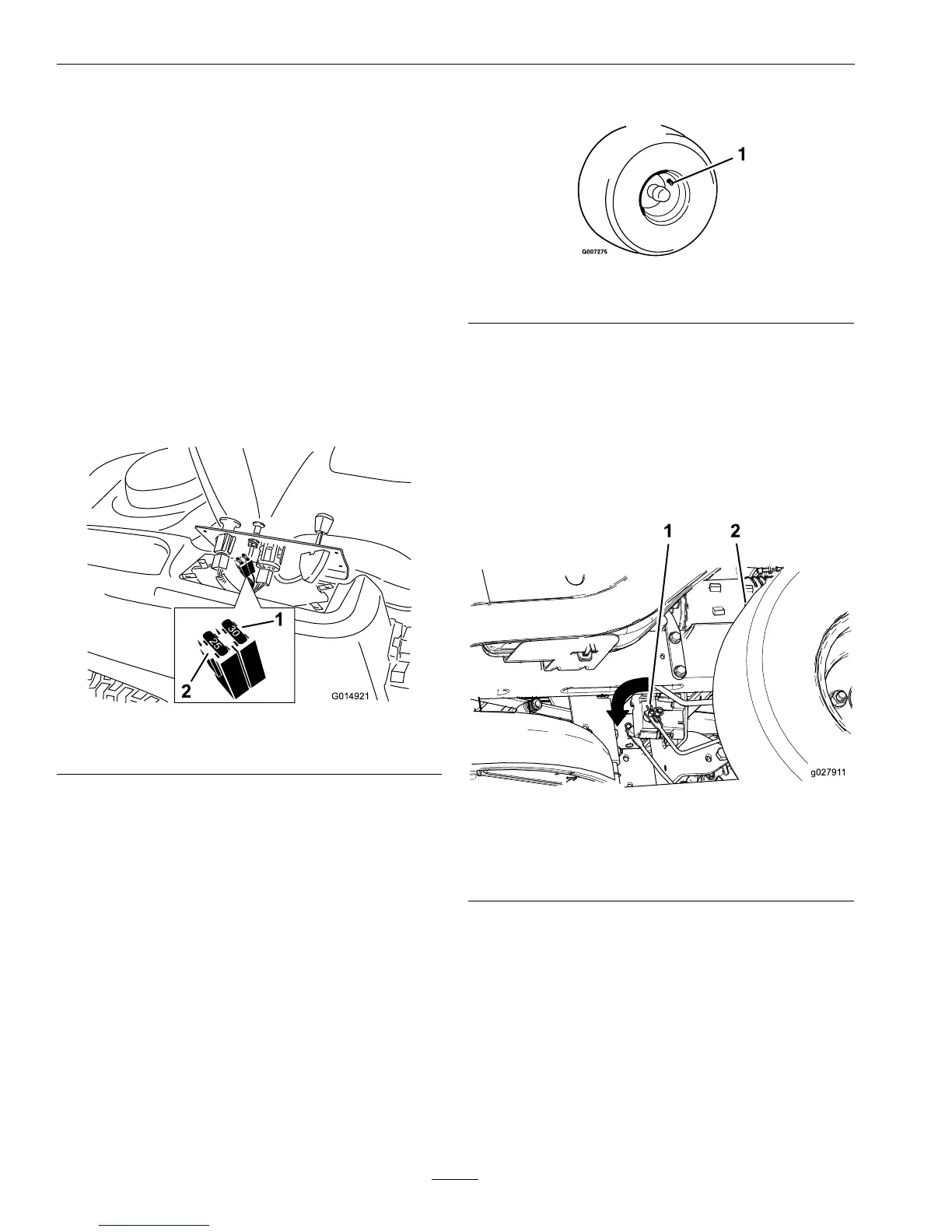

Checkthepressureatthevalvestem(Figure52).

Checkthetireswhentheyarecoldtogetthemost

accuratepressurereading.

RearTires:13psi(90kPa)

FrontTires(casterwheels):13psi(90kPa)

Figure52

1.Valvestem

ReleasingtheElectricBrake

ServiceInterval:Asrequired

Theelectricbrakecanbereleasebymanuallyrotating

thelinkarmsforward.Oncetheelectricbrakeis

energizedthebrakewillreset.

Toreleasethebrake:

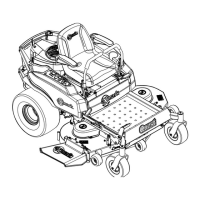

Figure53

1.Rotatebrake-link

armforwardonthe

electric-brake-control

module

2.Leftreartire

1.Turntheignitionkeytothe“OFF”positionor

disconnectthebattery

2.Locatetheshaftswherethebrakelinkarmsare

connectedonbothsidesoftheelectricbrake.

3.Rotatetheshaftforwardtoreleasethebrake.

CheckingtheHydraulicOil

Level–50InchOnly

ServiceInterval:Every25hours

52

Loading...

Loading...