Maintenance

CleaningtheFoamandPaperElements:

FoamElement:

Washthefoamelementwithwater.

Important:Replacethefoamelementifitis

tornorworn.

PaperElement:

1.Lightlytaptheelementonaatsurfacetoremove

dustanddirt.

2.Inspecttheelementfortears,anoilylm,and

damagetotheseal.

Important:Donotcleanthepaperelement

withpressurizedairorliquids,suchas

solvent,gas,orkerosene.Replacethepaper

elementifitisdamagedorcannotbecleaned

thoroughly.

TolearnmoreabouttheExmarktwin-cylinderengine

gotohttp://exmark.com/enginesorscantheQR

code.

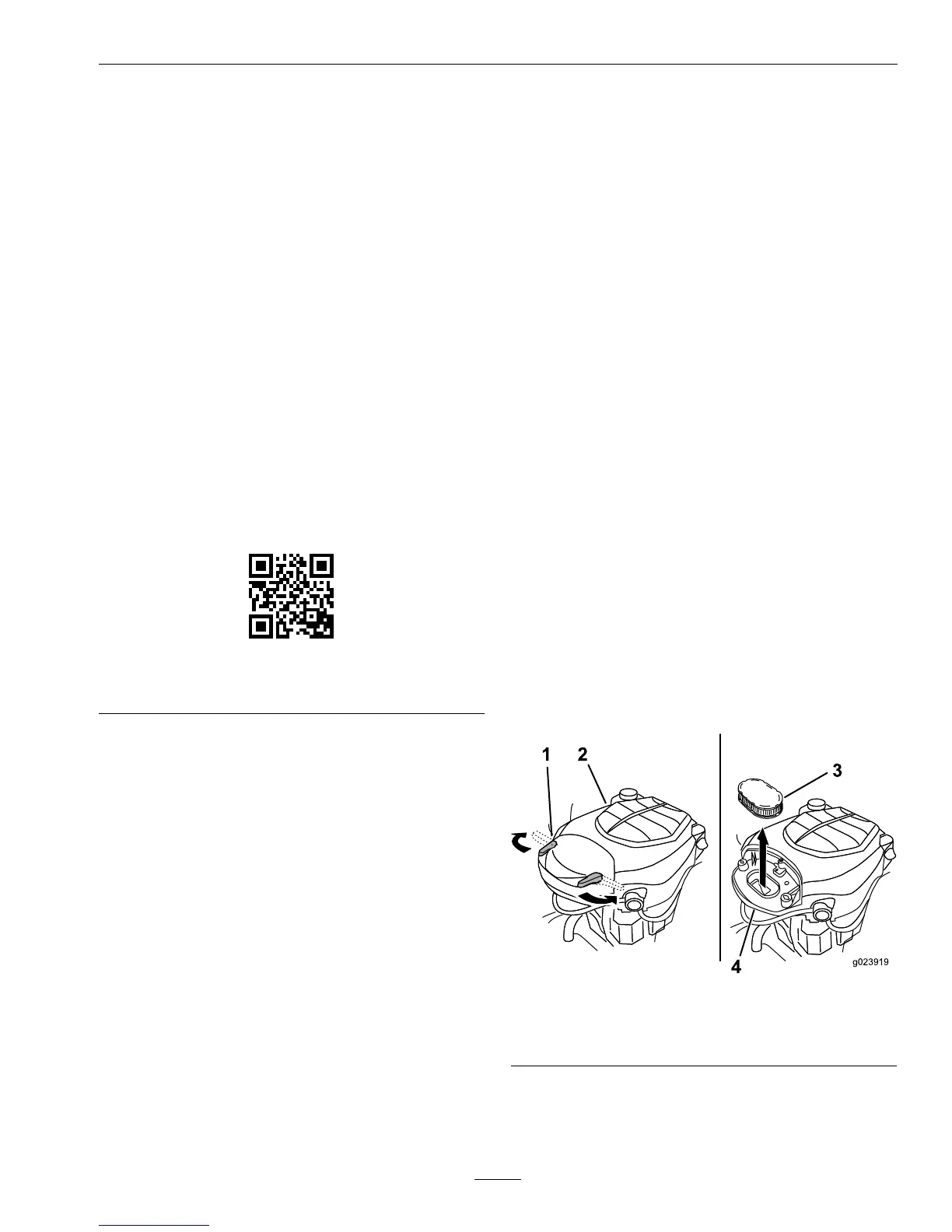

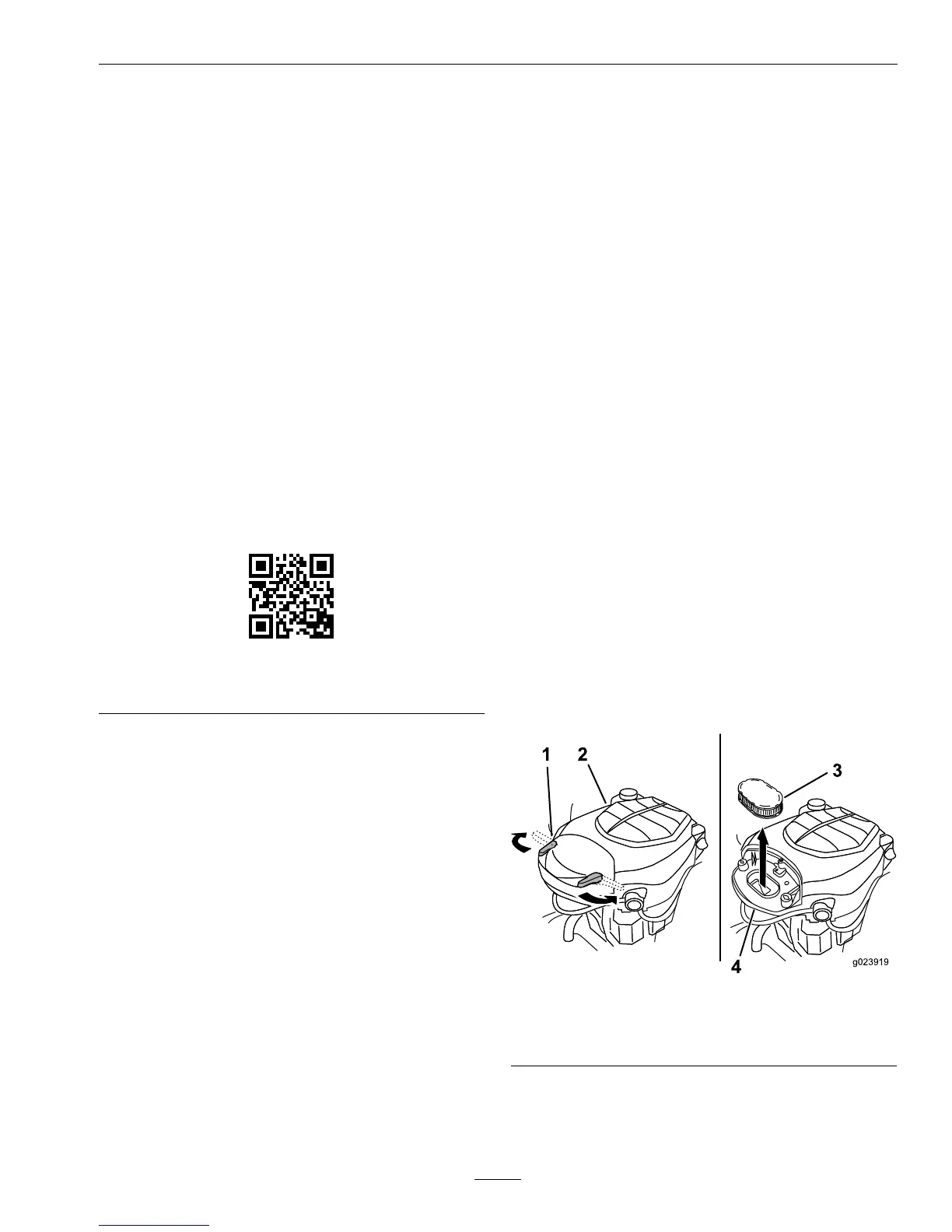

Figure29

708ccEngine

ServicingtheAirCleaner–Kohler

Engine

ServiceInterval:Beforeeachuseor

daily—Checktheair

cleanerfordirty,looseor

damagedparts.

Every25hours—Service

orreplacetheaircleaner

pre-cleaner(moreoften

underextremelydusty,

dirtyconditions)(Kohler

engine).

Every50hours—Service

theaircleanerpaper

element(moreoften

underextremelydusty,

dirtyconditions)(Kohler

engine).

Every100hours—Replace

theaircleanerpaper

element(moreoften

underextremelydusty,

dirtyconditions)(Kohler

engine).

Thisengineisequippedwithareplaceable,high

densitypaperair-cleanerelement.Checktheair

cleanerdailyorbeforestartingtheengine.Checkfor

abuildupofdirtanddebrisaroundtheair-cleaner

system.Keepthisareaclean.Also,checkforlooseor

damagedcomponents.Replaceallbentordamaged

air-cleanercomponents.

Note:Operatingtheenginewithlooseordamaged

air-cleanercomponentscouldallowunlteredairinto

theengine,causingprematurewearandfailure.

Note:Servicetheaircleanermoreoftenunder

extremelydusty,dirtyconditions.

1.Parkthemachineonalevelsurfaceanddisengage

thebladecontrolswitch.

2.Stopthemachineandreleasethetraction-control

pedaltoplacethemachineintheneutralposition,

engageparkingbrake,stoptheengine,removethe

key,andwaitforallmovingpartstostopbefore

leavingtheoperatingposition.

3.Rotatethelatchesoutward.

4.Removethecovertoaccesstheair-cleaner

element(seeFigure30).

Loading...

Loading...