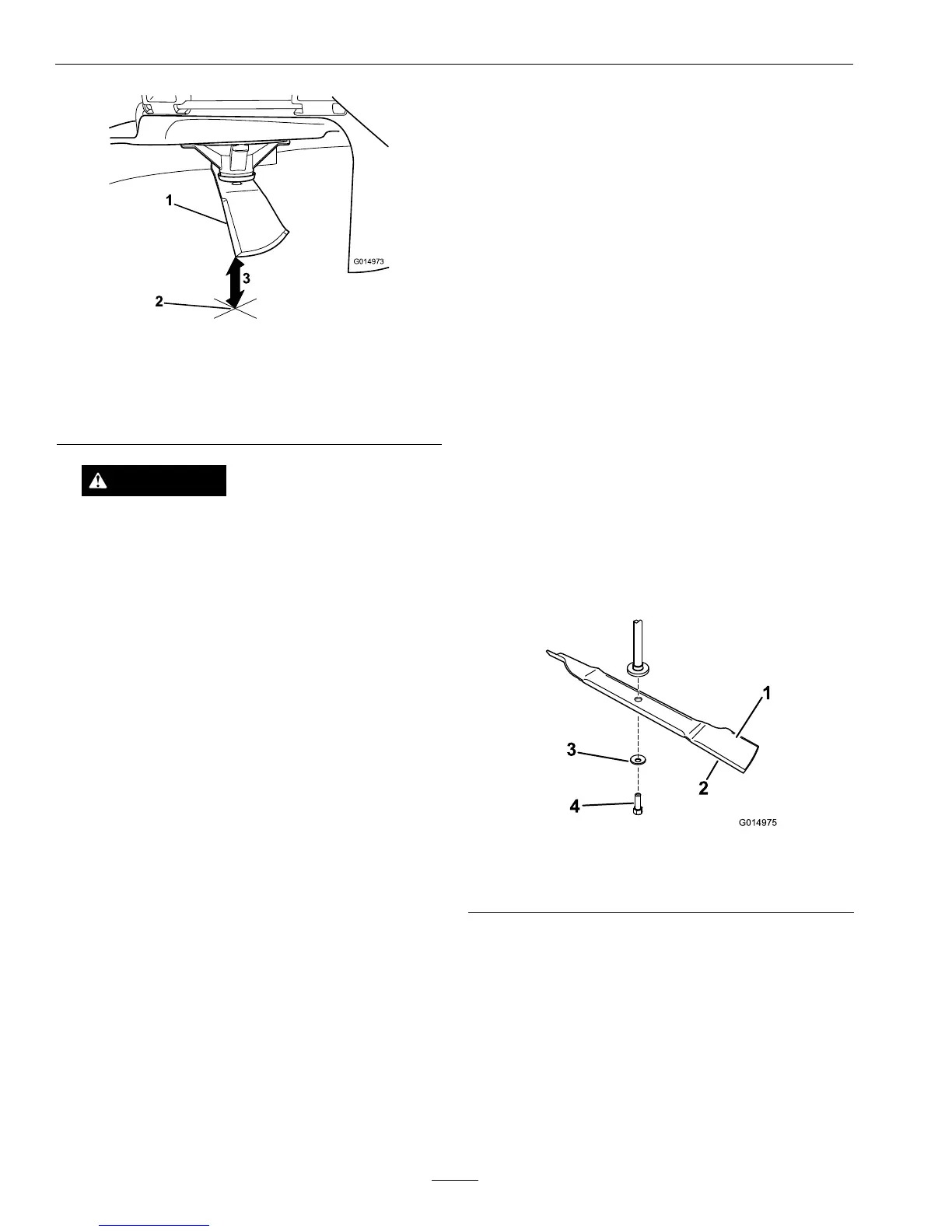

Figure43

1.Opposingbladeedge,inpositionformeasuring

2.Levelsurface

3.Secondmeasureddistancebetweenbladeandsurface

(B)

WARNING

Awornordamagedbladecanbreak,anda

pieceofthebladecouldbethrownintothe

operator'sorbystander'sarea,resultingin

seriouspersonalinjuryordeath.

•Inspectthebladeperiodicallyforwearor

damage.

•Replaceawornordamagedblade.

A.IfthedifferencebetweenAandBisgreater

than1/8inch(3mm)replacethebladewitha

newblade.RefertoRemovingtheBladesand

InstallingtheBlades.

Note:Ifabentbladeisreplacedwithanew

oneandthedimensionobtainedcontinues

toexceed1/8inch(3mm),thebladespindle

couldbebent.ContactanAuthorizedExmark

Dealerforservice.

B.Ifthevarianceiswithinconstraints,moveto

thenextblade.

Repeatthisprocedureoneachblade.

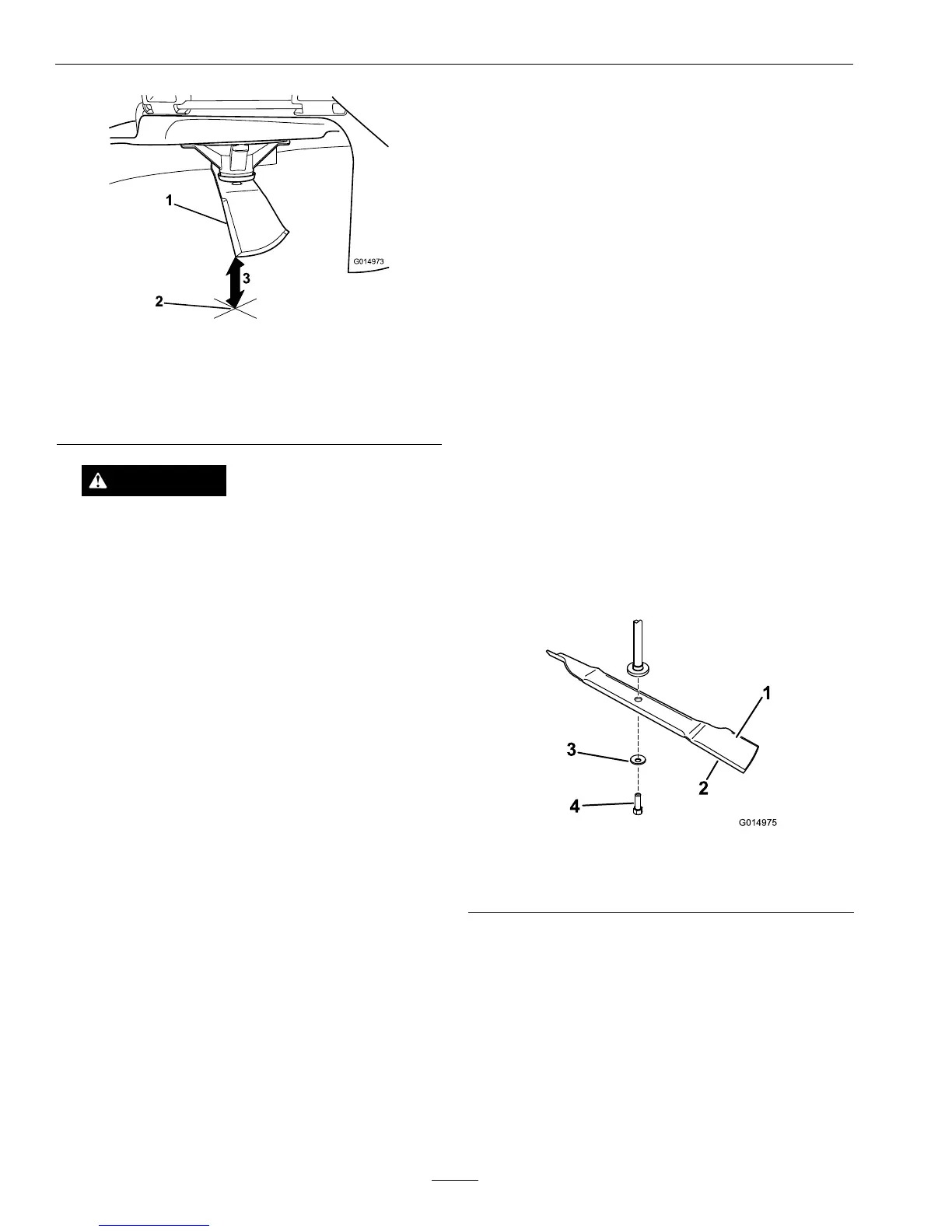

CheckingforLooseBladesor

DamagedSpringDiscWashers

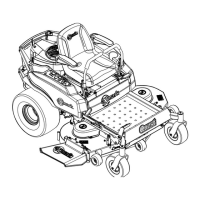

1.Placeawrenchonthebladeboltandtorqueto

35-65ft-lb(47-88N-m).

2.Withthewrenchstillonthebladebolt,hold

thebladespindlestationaryandusingaragor

thicklypaddedglove,trytorotatetheblade.Ifthe

bladerotatesrelativetothespindleguardwithout

furthertighteningthebladebolt,thespring

discwasherhasbeenattenedordamagedand

theboltandwasherassemblymustbereplaced

(Figure44).RefertoRemovingtheBladesand

InstallingtheBlades.

3.Oncethebladehasbeenremoved,inspectthe

springdiscwasher.Ifthewasherappearstobe

damaged(thewashersurfacehasbeenmarred)

orattened,theboltandwasherassemblymust

bereplaced.

RemovingtheBlades

Thebladesmustbereplacedifasolidobjectishit,if

thebladeisoutofbalance,orthebladeisbent.To

ensureoptimumperformanceandcontinuedsafety

conformanceofthemachine,usegenuineExmark

replacementblades.Replacementbladesmadeby

othermanufacturersmayresultinanunsafemachine.

Holdthebladeendusingaragorthickly-padded

glove.Removethebladebolt,curvedwasher,and

bladefromthespindleshaft(

Figure44).

Loading...

Loading...