Maintenance

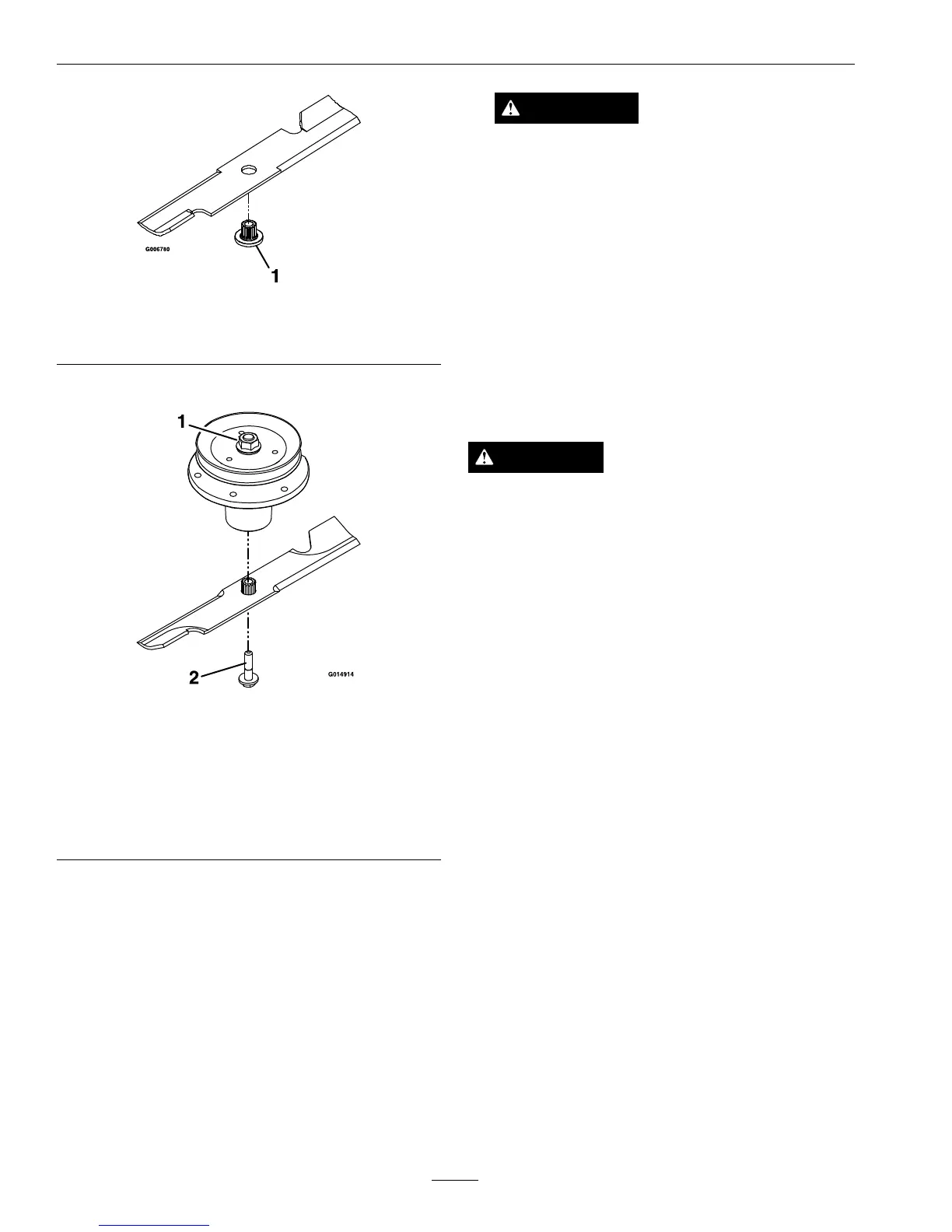

Figure18

1.Installbushinginbladepriortoinstallingbushingin

spindle.

B.Installbushing/bladeassemblyintospindle.

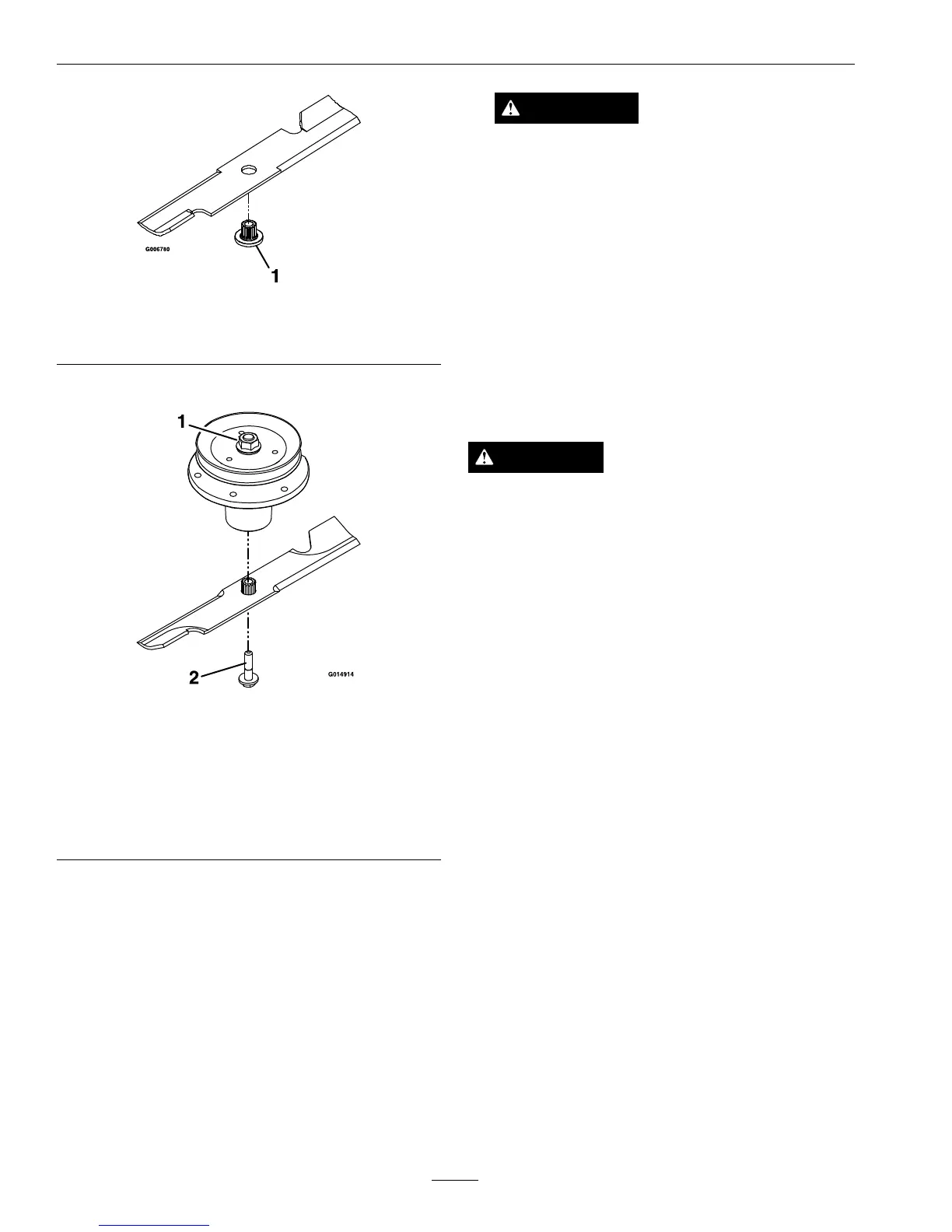

Figure19

1.Usewrenchherefor

bladeinstallation.This

nuthasbeentorquedto

130-160ft-lb(176–217

N-m)

2.T orqueto50-60ft-lb

(68-81N-m)Apply

lubricanttothreads

asneededtoprevent

seizing.Copper-based

anti-seizepreferable.

Greaseacceptable

substitute.

C.Applylubricanttothreadsofbladeboltas

neededtopreventseizing.Copper-based

anti-seizepreferable.Greaseacceptable

substitute.Installbladeboltngertight.Place

wrenchonthetopspindlenutthentorquethe

bladeboltsto50-60ft-lb(68-81N-m).

WARNING

Incorrectinstallationofthebladeor

componentsusedtoretainthebladecan

bedangerous.Failuretousealloriginal

componentsandassembledasshowncould

allowabladeorbladecomponenttobe

thrownoutfromunderthedeckresultingin

seriouspersonalinjuryordeath.

AlwaysinstalltheoriginalExmarkblades,

bladebushings,andbladeboltsasshown.

CheckSafetyInterlock

System

ServiceInterval:Beforeeachuseordaily

CAUTION

Ifsafetyinterlockswitchesaredisconnected

ordamagedthemachinecouldoperate

unexpectedlycausingpersonalinjury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlockswitches

dailyandreplaceanydamagedswitches

beforeoperatingthemachine.

UnderstandingtheSafetyInterlockSystem

Thesafetyinterlocksystemisdesignedtopreventthe

mowerbladesfromrotatingunless:

•Therightsidemotioncontrolleverismovedto

thecenter,operatingposition.

•Thebladecontrolswitch(PTO)ispulledon.

Thesafetyinterlocksystemisdesignedtostop

themowerbladesifyoumoveorreleasetheright

sidemotioncontrolleverintothePTOdisengage

position.

•Therightsidemotioncontrolleverismovedto

thecenter,operatingposition,theparkingbrake

isengaged,andthebladecontrolswitch(PTO)is

pulledon.

CheckingtheSafetyInterlockSystem

1.Starttheengine.

2.Settheparkingbrake.

3.Movethemotioncontrolleversforward.

Theengineshouldinitiateshutdownafter

momentarypause.

4.Starttheengineandreleasetheparkingbrake.

30

Loading...

Loading...