Maintenance

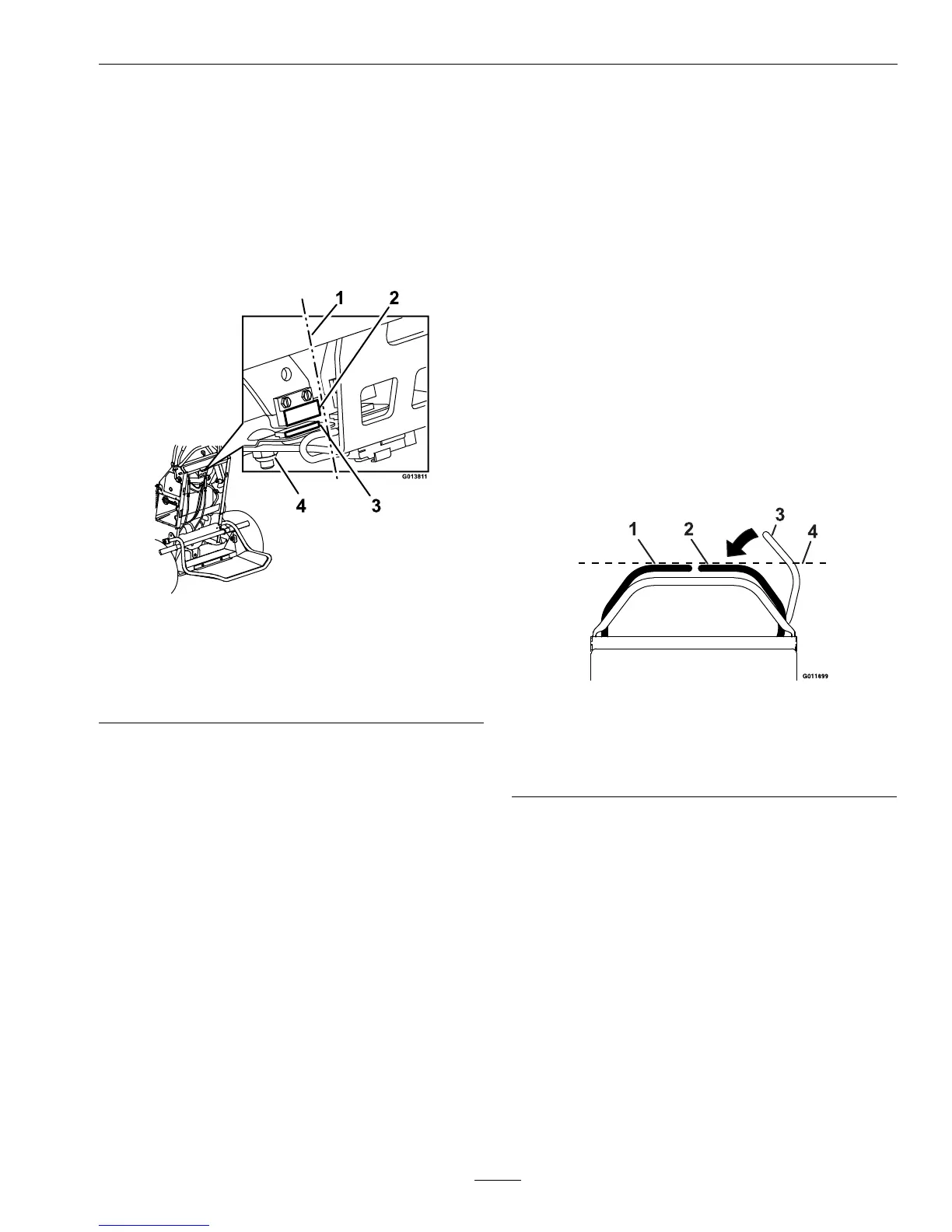

6.CheckthealignmentontheLHandRHneutral

switchesupperandlowersurfaces(reference

Figure39).Iftheyarenotinalignment,loosenthe

hardwareonthelowerneutralswitchandadjustit

forwardorrearwardasnecessary.Oncealigned,

tightenthehardware.Checktheneutralswitch

alignmentagainasthedeckismovedthroughthe

highestandlowestcutheightsetting;adjustthe

lowerneutralswitchsurfaceifnecessary.

Figure39

1.Alignmentreference

4.Lowerneutralswitch

surface

2.Upperneutralswitch

surface

5.Hardware

3.Switchmountingplate

7.Adjusttheupperneutralswitchsurfaceleft

orrightifside-to-sidealignmentisneeded.

Theupperandlowerswitchesshouldbeas

closetogetheraspossiblewithouttouching

(approximately.06inch(1.5mm)gapisdesirable).

Theswitchmountingplatecanbemovedupor

downtoadjustthepositionofthelowerneutral

switch.

8.Checkthefunctionoftheneutralswitchesby

temporarilyreplacingthekey.Withtheengine

off,turntheignitionswitchtothe“ON”position.

LocatetheLCDindicatorinthemessagedisplay.

Raiseandlowerthedeck.

A.Iftheindicatordisplayswhilemovingthedeck

upanddown,theneutralswitcheshavebeen

adjustedproperlyandnofurtheradjustment

isnecessary.

B.Iftheindicatordoesnotstaylitwhilemoving

thedeckupanddown,contactanAuthorized

ServiceDealer.Removethekey.

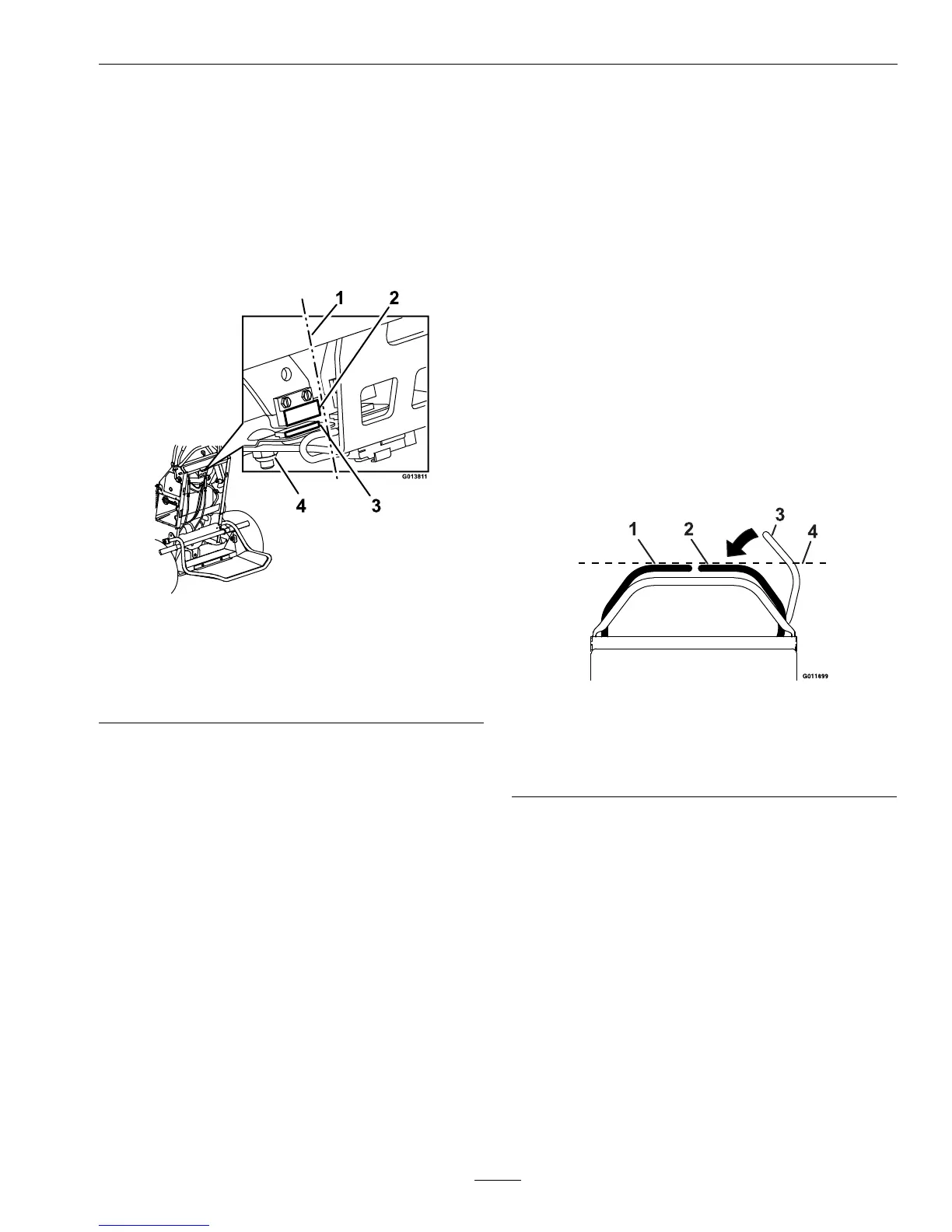

AdjustRHMotionControl

HandlePosition

Ifthemotioncontrolleversdonotalignhorizontally,

adjusttherightsidemotioncontrollever.

Note:Adjustthehorizontalalignmentbeforethe

fronttobackalignment.

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Pushtherightmotioncontrolleverdownoutof

lockedneutralposition.

3.Checkifitalignshorizontallywiththeleftmotion

controllever.

Figure40

1.LHMotioncontrollever

2.RHMotioncontrollever

3.RHMotioncontrolleverinPTOdisengagedposition

4.Checkthehorizontalalignmenthere

4.Toadjusttherightmotioncontrollever

horizontally,thecamneedstobeadjusted.

5.Releasethecushionfromtherearofthemachine.

6.Loosenthenutandboltholdingthecam.

7.Adjustthecamuntilitalignswiththeleftmotion

controlleverandtightenthenutandboltforthe

cam.

43

Loading...

Loading...