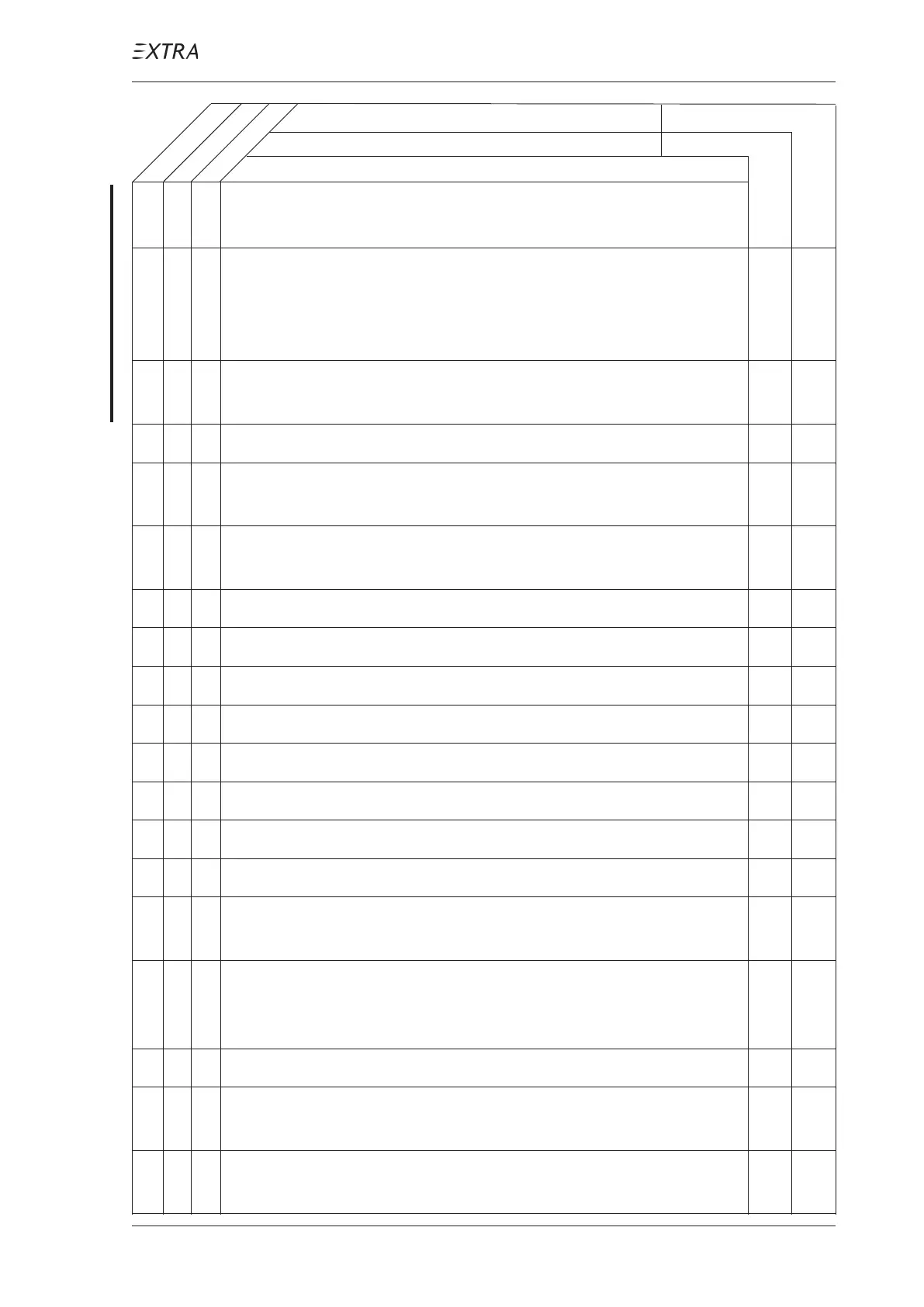

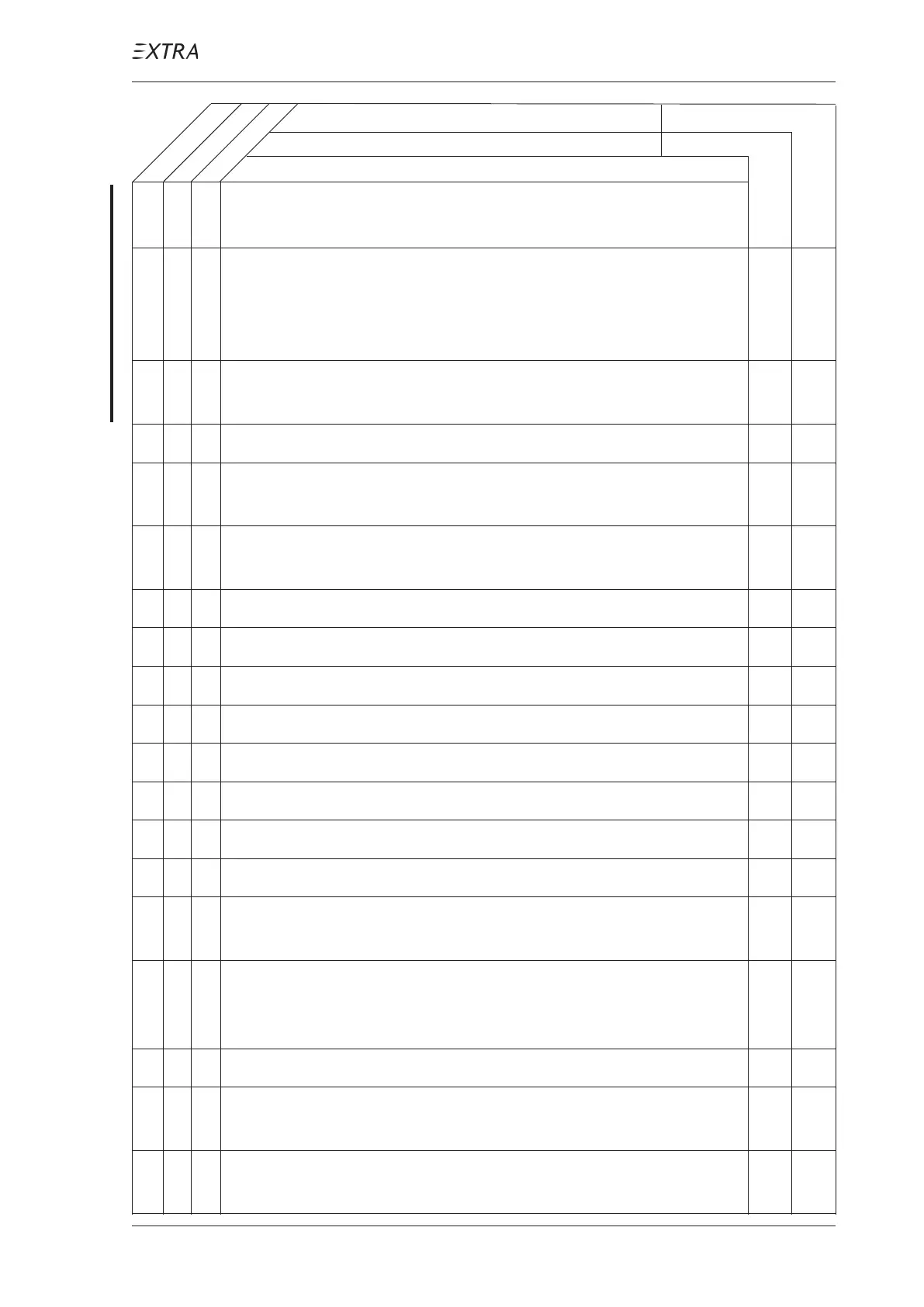

MAINTENANCE MANUAL EXTRA 300/SC

CHAPTER 05

PAGE 19

PAGE DATE: 1. August 2014

Inspector:

Mechanic:

Date:

Serial No.:

Inspections

as specified

each 50 hours

each 100 hours

O 3 Check hardware; inspect for corrosion, check whether buck-

les mate properly. Check the buckles for easy opening.

O 4 Check ratchet assembly; inspect for corrosion, loss of plating,

discoloration, slippage and wear; check for ease of operation.

If the harness does not pass the check, it has to be reworked or

replaced. Contact the harness manufacturer in case of doubt.

O 5 Check proper attachment of shoulder harness as per chapter

25-10-03.

Fuel system

O O 1 Inspect the fuel lines for leaks, security, chafing, dents and

cracks. Replace fuel lines as required.

O O 2 Inspect fuel selector valve for operation and proper pointer

indication.

O O 3 Drain fuel system.

O O 4 Check acro- and center tank attachment.

O O 5 Check acro-, center- and both wingtanks for leaks.

O O 6 Check boost pump.

O O 7 Check fuel filler caps for security and proper operation.

O O 8 Check proper seat and condition of sealing lip.

Flight controls

O O 1 Remove wing access panels.

O O 2 Inspect control surfaces for security of attachment, free

movement, dents, delaminations and cracks.

O O 3 Check spades visually for general condition. Inspect spade

support for corrosion, cracks and deformations. Ensure proper

attachment to aileron.

O O 4 Inspect elevator trim system for proper operation and rigging.

O O 5 Inspect hinges for condition, cracks and security; hinge bolts,

hinge bearings, selflocking nuts.

O O 6 Check free play in control system: torque tube, control sur-

faces, control stick, rod end bearing, deflector limiter.

SCHEDULED MAINTENANCE CHECKS

Maintenance Checks Schedule

Loading...

Loading...