MAINTENANCE MANUAL EXTRA 300/SC

CHAPTER 05

PAGE 20

PAGE DATE: 1. August 2014

Inspector:

Mechanic:

Date:

Serial No.:

Inspections

as specified

each 50 hours

each 100 hours

SCHEDULED MAINTENANCE CHECKS

Maintenance Checks Schedule

O

1

O O 7 Lubricate rear torque tube bearing.

O O 8 Lubricate aileron rodend bearings, trim flap hinges and trim

lever bolt.

O O 9 Check rudder cable system including sleeves, fairleads, pul-

leys and cable retracting springs per FAA-AC 43.13-1A.

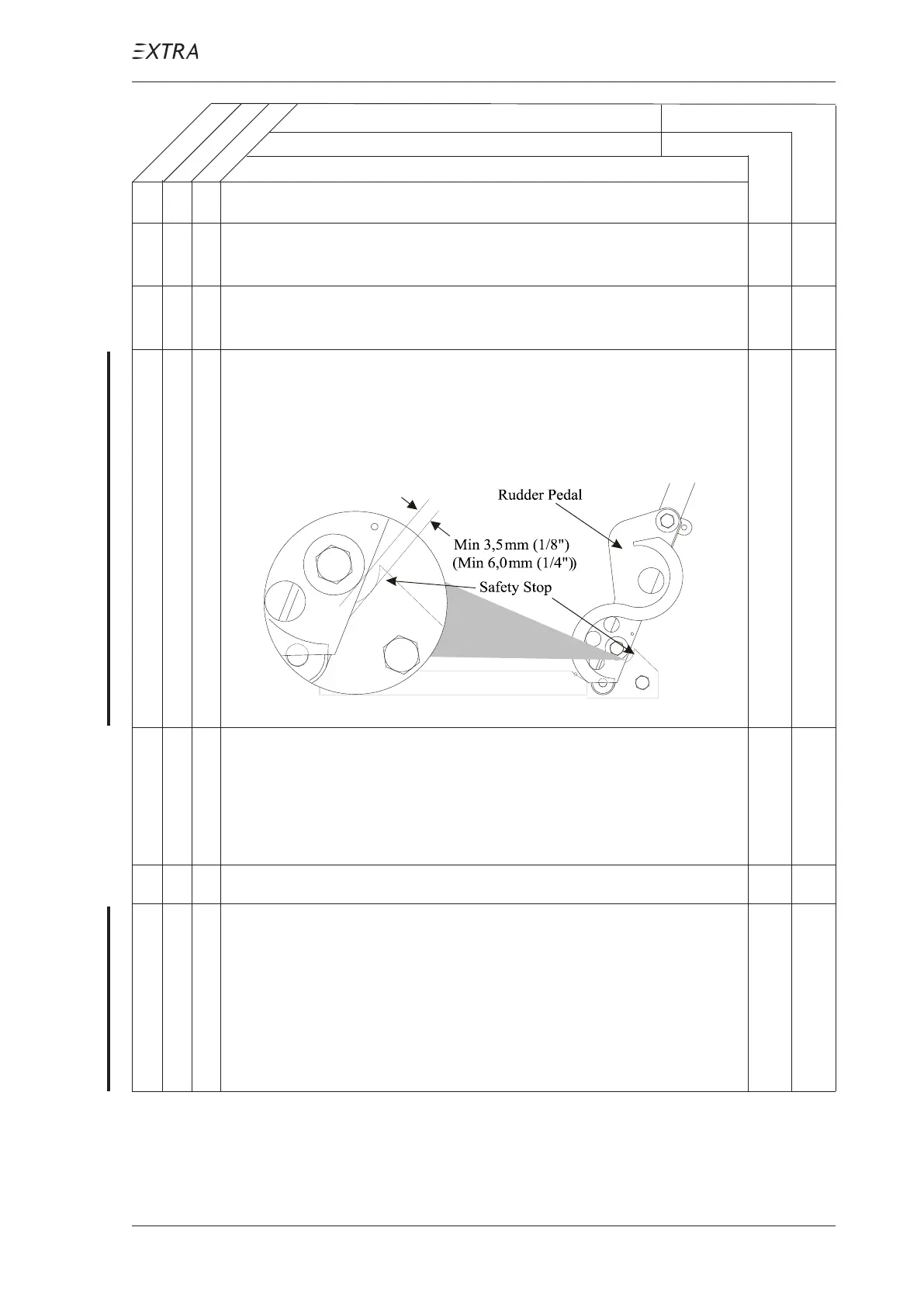

O 10 Check for minimum 3.5 mm (1/8") clearance of rudder pedal

versus safety stop when fully deflected for rudder cables

having 50 h flight time minimum. On newly installed rudder

cables the minimum spacing is 6 mm (1/4"). This check is to

be performed with zero loading on the rudder pedals.

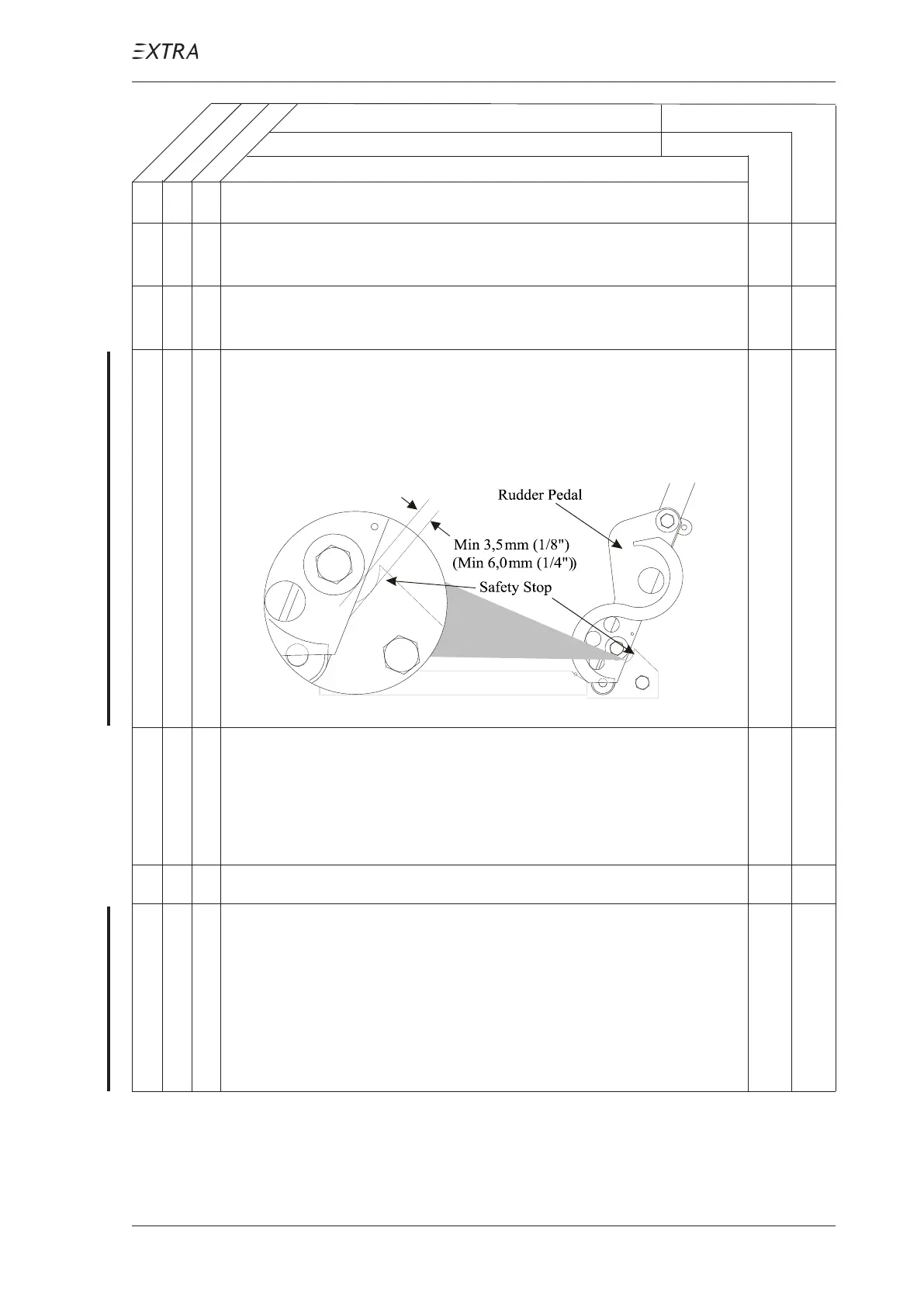

O 11 Rough check of safety stop clearance. With a force of approx.

90 kg (200 lbs) acting on the fully deflected rudder pedal the

safety stop shall not be reached. If the stop is reached the

control system indicates a too high flexibility which needs to

be traced. In this case contact EXTRA for advice.

O O 12 Inspect all flight control ventilation holes for obstruction.

O 13 Visually inspect metal push/pull control rods for corrosion,

cracks, or other visible damage, especially at their end fittings.

In case of suspected cracks, remove push/pull control rod,

strip the paint in the suspected area and carry out a detailed

inspection using a magnifying glass (x10). Replace the related

control rod in case a crack is found otherwise reapply surface

treatment and reinstall push/pull control rod.

1 each 25 hours

Loading...

Loading...