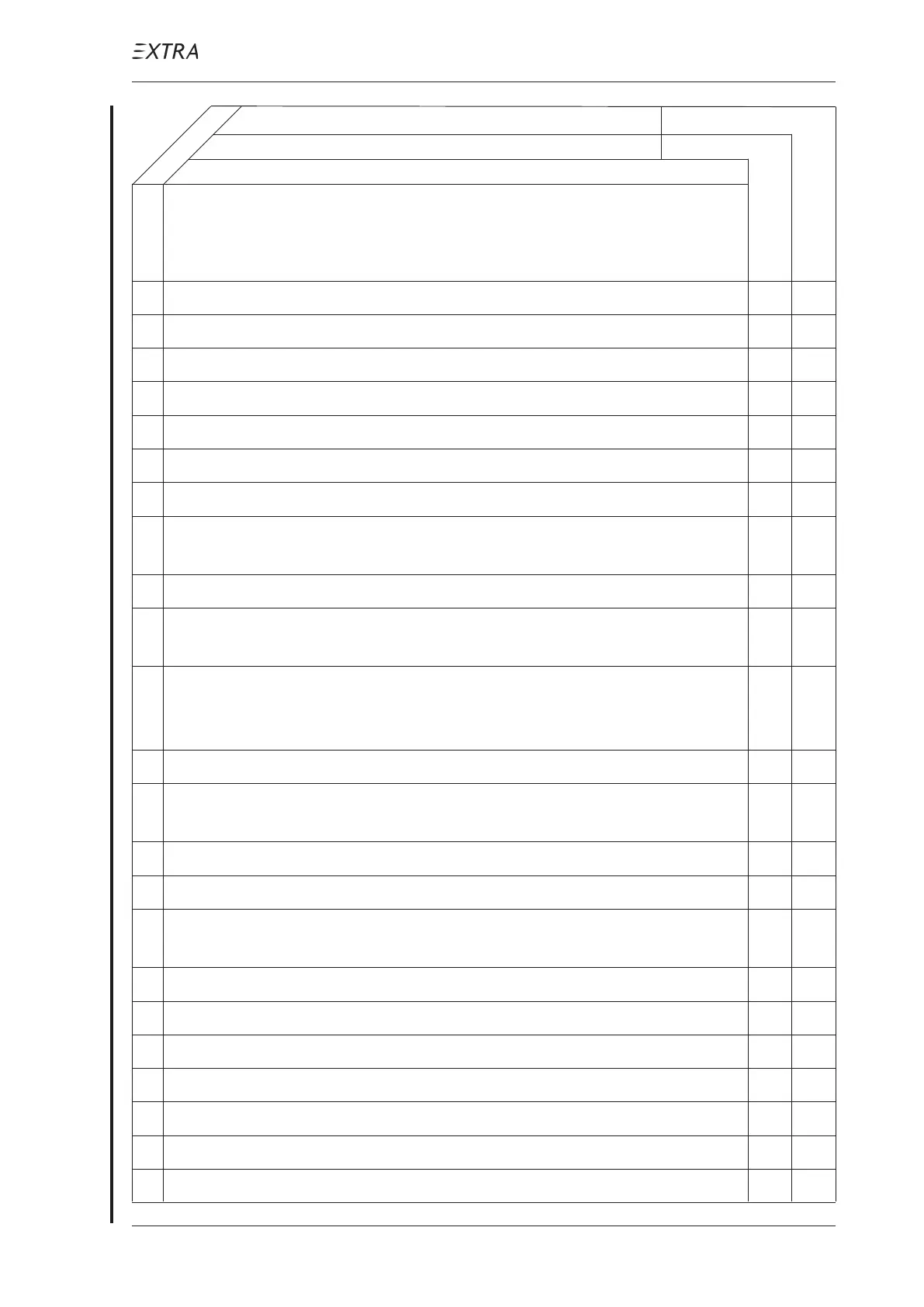

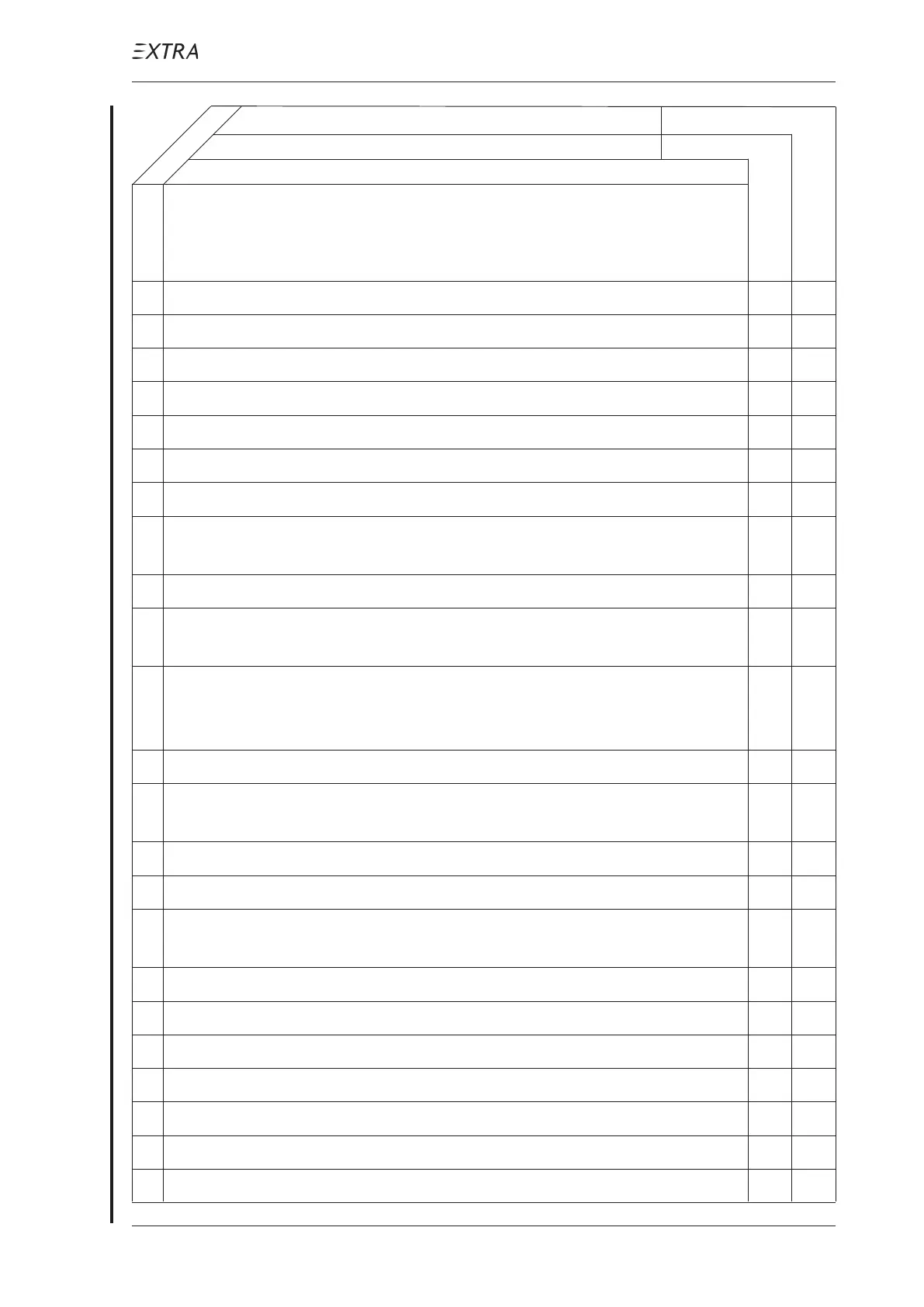

MAINTENANCE MANUAL EXTRA 300/SC

CHAPTER 05

PAGE 29

PAGE DATE: 1. August 2014

O 6 Inspect spades visually for general condition. Check spade support for

corrosion, cracks and deformations. Ensure proper attachment to

aileron.

O 7 Inspect ventilation holes for obstruction.

Surface general

O 8 Check paint visually for general condition (blisters etc.).

O 9 Check laminate for erosion, scratches and nicks.

Rudder

O 1 Remove rudder as per Chapter 27.

O 2 Inspect tip area bonding to the skin laminate by coin tapping.

O 3 Inspect skin to lower horn rib bonding for delaminations by coin

tapping and for cracks.

O 4 Inspect skin to spar bonding for delamination by coin tapping.

O 5 Inspect trailing edge bonding for cracks and delaminations by coin

tapping.

O 6 Detailed visual inspection of mounting brackets for damages and

cracks. Ensure proper attachment. Replace bolts and stop nuts. Check

for proper torque in accordance with Chapter 20-10-03.

O 7 Remove bottom hinge bracket and bellcrank as per Chapter 27.

O 8 Inspect rudder structure in the area of the bottom hinge for cracks and

delamination by coin tapping.

O 9 Reinstall bottom hinge bracket and bellcrank as per Chapter 27.

O 10 Check bellcrank for damage, cracks and proper attachment.

O 11 Visually inspect ventilation holes for obstruction. Refer to Chapter 05-

20-01, figure 1 "Drain and Vent Holes".

O 12 Check paint visually for general condition (blisters etc.).

O 13 Check laminate for erosion, scratches and stone nicks.

Vertical Stabilizer

O 1 Remove vertical stabilizer as per Chapter 55.

Leading edge

O 2 Check surface for erosion, scratches, stone nicks and impact damages.

O 3 Check left to right shell bonding for dents, cracks and delamination.

Inspector:

Mechanic:

Inspections

Date:

Serial No.:

1000 hours

SCHEDULED MAINTENANCE CHECKS

Significant Items Inspection

Loading...

Loading...