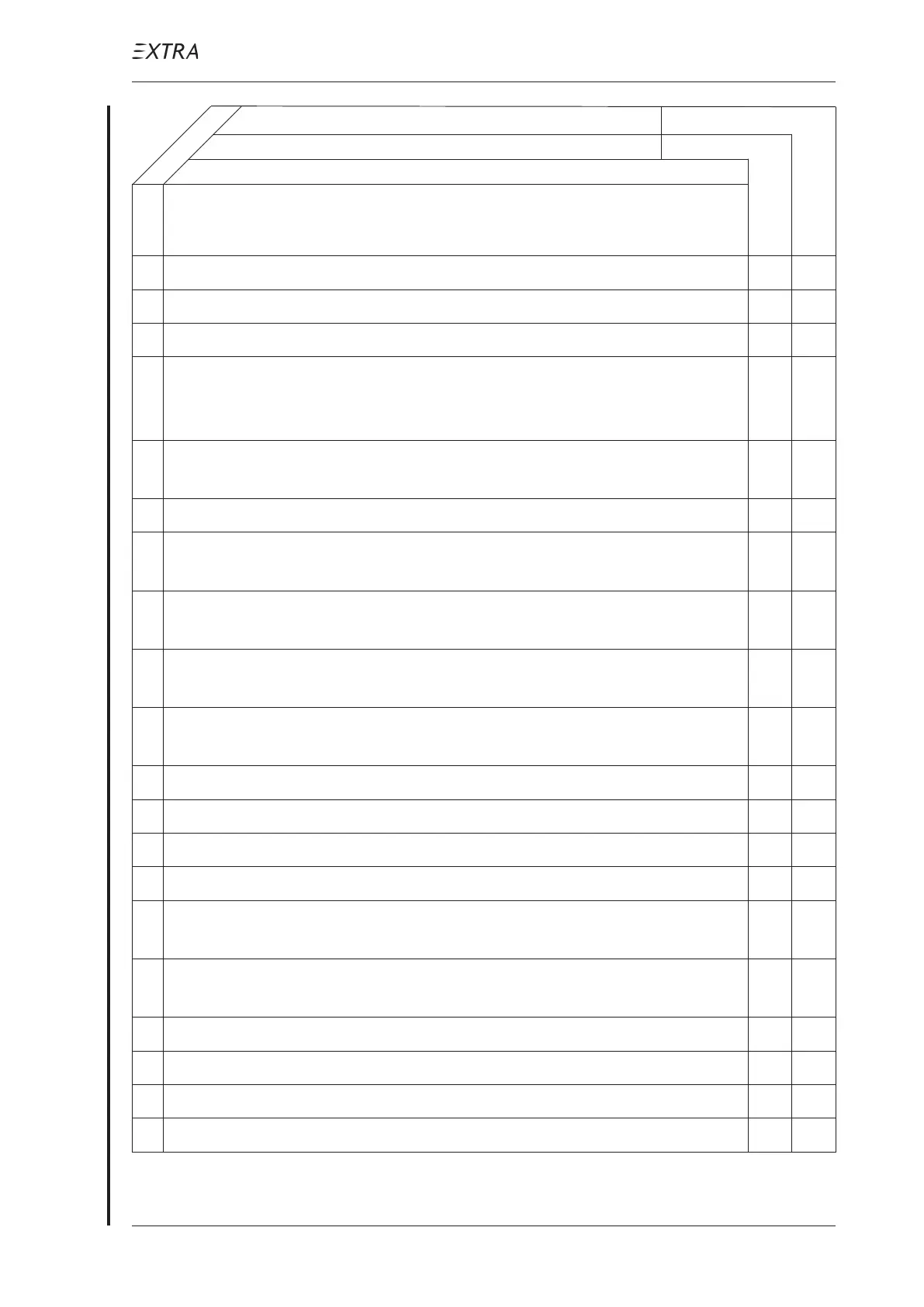

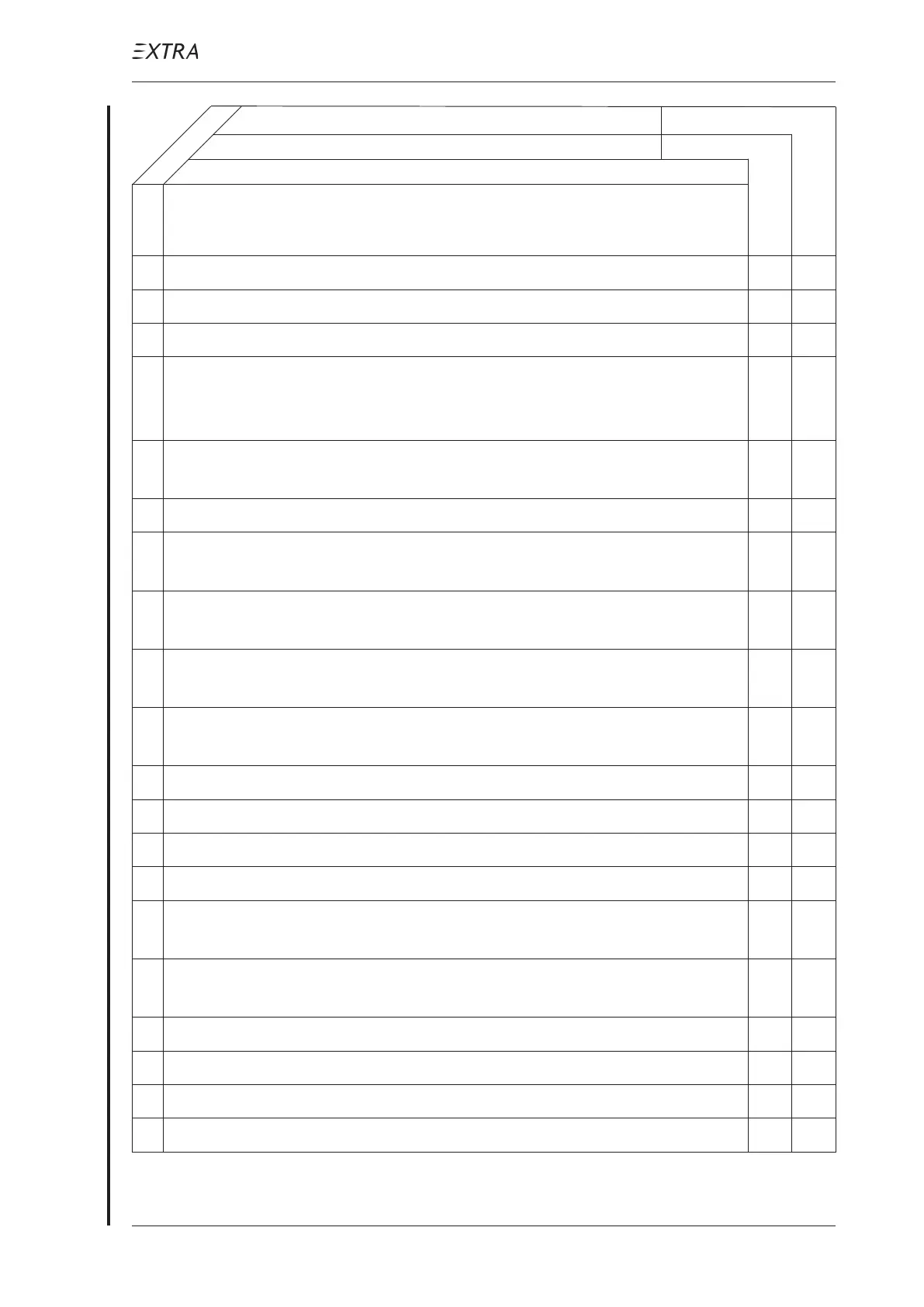

MAINTENANCE MANUAL EXTRA 300/SC

CHAPTER 05

PAGE 33

PAGE DATE: 1. August 2014

O 12 Check condition of trim Bowden cable. Inspect for buckles and chaf-

ing.

Main landing gear

O 1 Remove landing gear as per Chapter 32.

O 2 Remove wheels and brakes as per Chapter 32.

O 3 Visually inspect complete main landing gear spring for dents, cracks

and deformations, especially in the area of mounting clamps and the

axle attachments.

O 4 Inspect main landing gear spring in the area of brakes for damage of

overheating.

O 5 Inspect the center bushing for wear and looseness.

O 6 Check mounting clamps for damage and corrosion. Inspect for dents

and cracks.

O 7 Inspect mounting clamp bolts and nuts for fretting, wear, damage, and

stretch. Check for proper torque (refer to Chapter 20-10-03).

O 8 Check brake discs for warping and wear. Inspect wheel brake cylinder

mounting bracket for wear.

O 9 Inspect brake lines for leakage, dents, cracks, chafing, kinks and

security of anchorage.

O 10 Replace axle attachment bolts and nuts.

O 11 Check tires for general condition.

Tail-wheel landing gear

O 1 Inspect glass fibre spring visually for dents, cracks and delaminations.

O 2 Inspect mounting bolts and nuts for fretting, wear, damage, stretch and

proper torque.

O 3 Check tail-wheel for general condition and function. Pay attention to

the free movement of the rudder.

O 4 Check connector springs for light precompression.

O 5 Inspect wheel fork visually for damage, dents, cracks and corrosion.

O 6 Inspect axle bolt and nut for fretting, wear, damage, and stretch.

O 7 Check rubber tire for general condition.

Inspector:

Mechanic:

Inspections

Date:

Serial No.:

1000 hours

SCHEDULED MAINTENANCE CHECKS

Significant Items Inspection

Loading...

Loading...