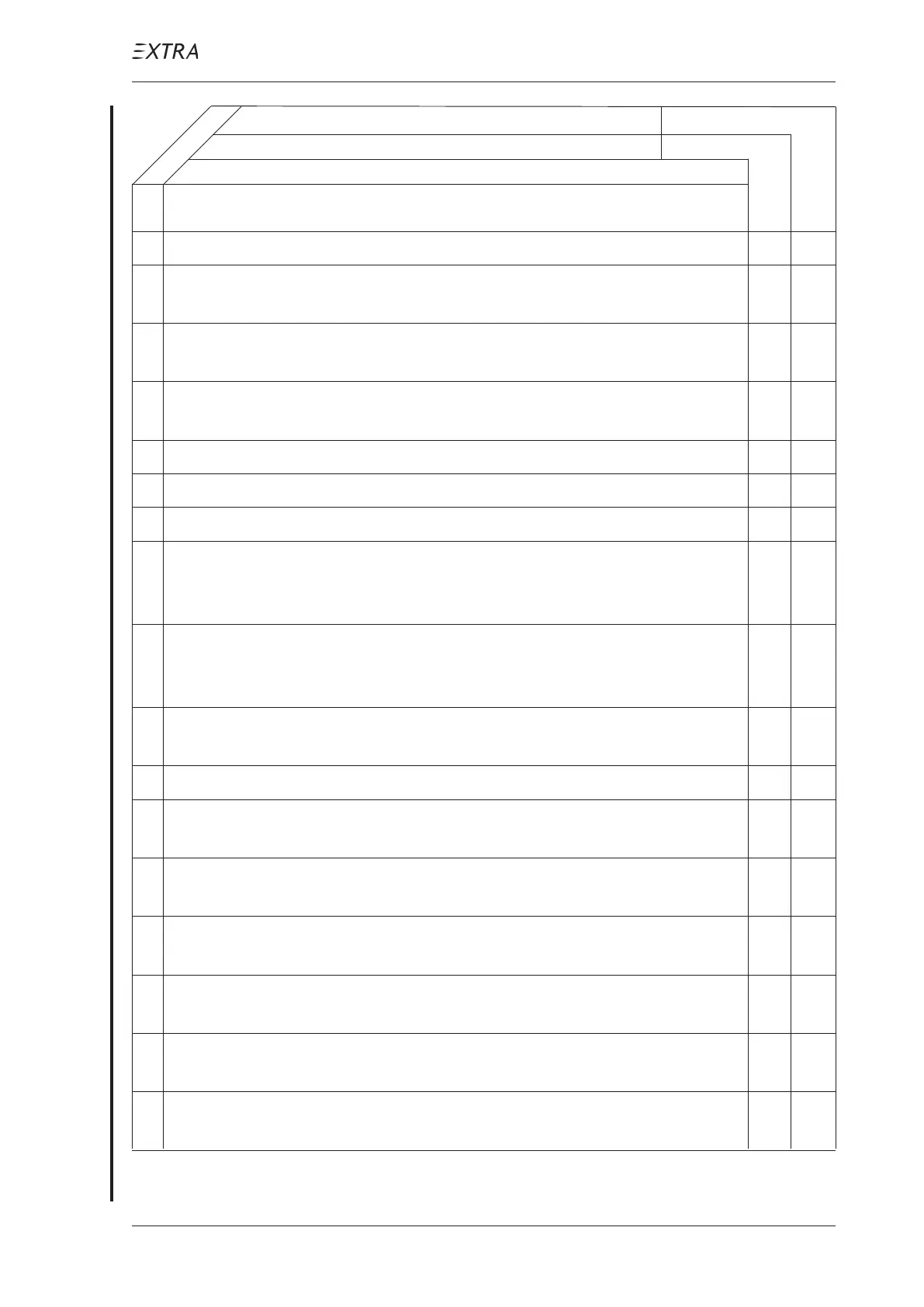

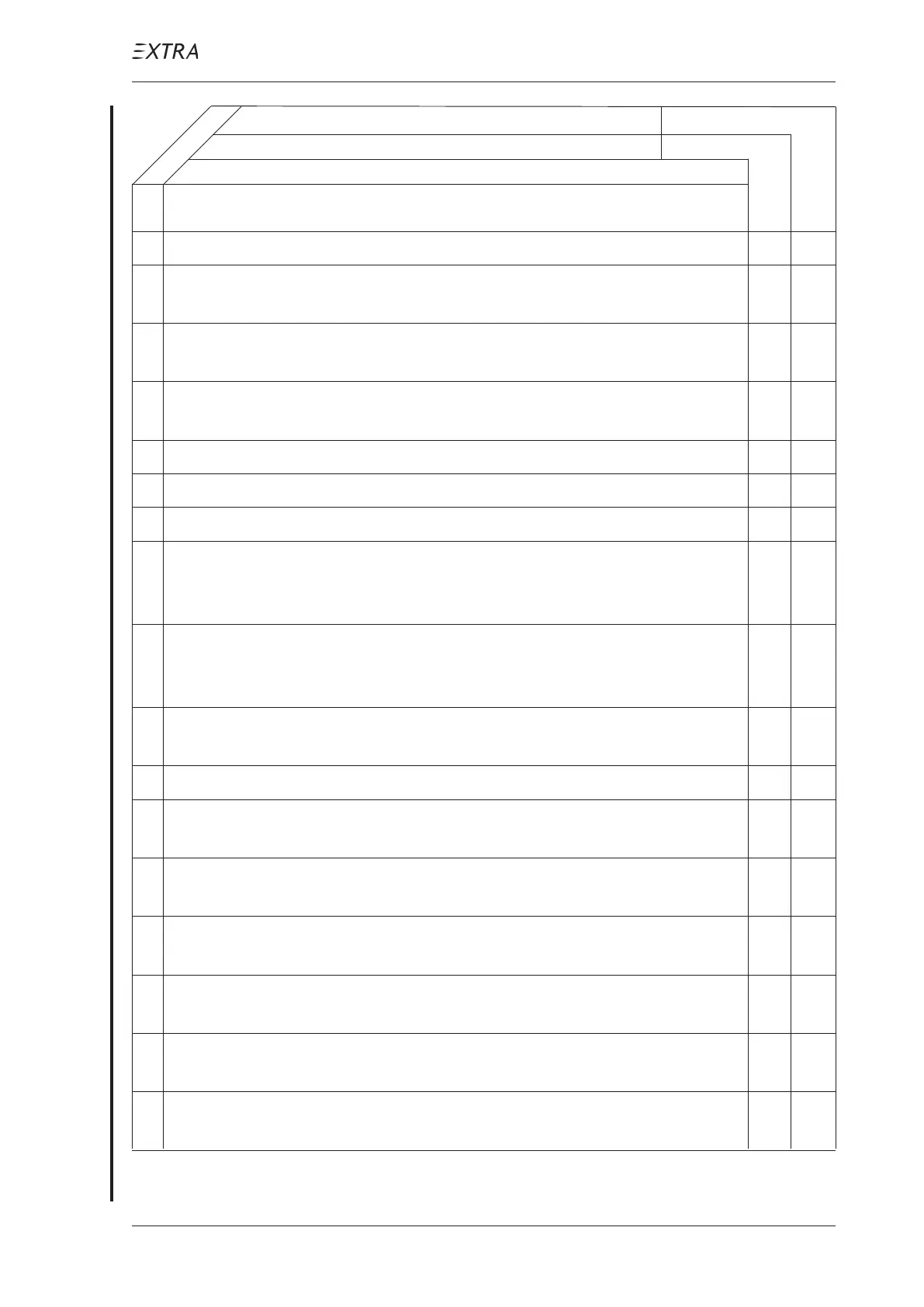

MAINTENANCE MANUAL EXTRA 300/SC

CHAPTER 05

PAGE 34

PAGE DATE: 1. August 2014

Inspector:

Mechanic:

Inspections

Date:

Serial No.:

1000 hours

Engine compartment

O 1 Remove engine cowling halves.

O 2 Check firewall for dents, cracks and deformation. Visual inspection of

LJF PR 812 seals for porosity and general condition.

O 3 Inspect tubular engine mount for dents, cracks and corrosion. Check all

bolts for security and condition.

O 4 Visual inspection of rubber mounts (shock mounts) for porosity and

general condition.

O 5 Inspect flexible hoses for damage and leakage.

O 6 Check electric wiring for proper connection.

O 7 Check electrical bonding braids for proper connection.

O 8 Visual inspection of inverted oil system for general condition accord-

ing to CHRISTEN 801 instruction. Refer to the applicable TEXTRON

LYCOMING Operator`s or Maintenance Manual (refer to Chapter 1).

O 9 Carry out general engine check as instructed by the applicable

TEXTRON LYCOMING Operator`s or Maintenance Manual (refer to

Chapter 01).

O 10 Visual inspection of cowling for dents, cracks, delamination and

smoke marks.

Hardware

O 1 Check harness attachment fittings for cracks, deformations and corro-

sion.

O 2 Check bolts and nuts in critical areas for fretting, wear, damage, stretch,

proper torque and safety.

O 3 Visual inspection of tank fastening straps for cracks, damage and

corrosion.

O 4 Visually inspect tanks and tank shell for leakage. Check proper drain-

age.

O 5 Visual inspection of battery fastening straps for cracks, damage and

corrosion.

O 6 Inspect the "quick pins" of the seat adjustment for cracks, deforma-

tions, wear and corrosion. Check proper function.

SCHEDULED MAINTENANCE CHECKS

Significant Items Inspection

Loading...

Loading...