Section:Chapter: 3

Page

JOG MODE2

JOGGING THE AXES

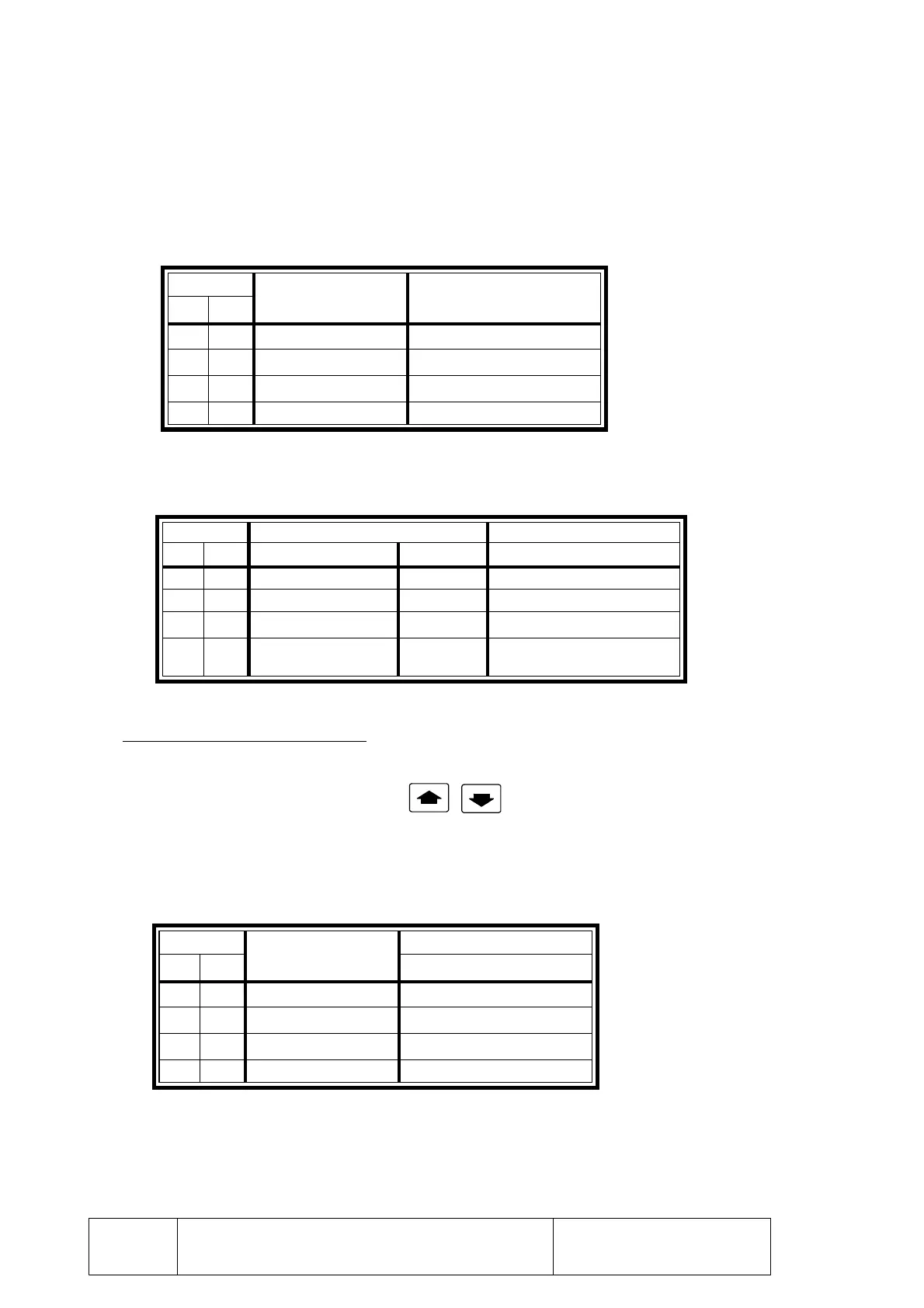

Pin

JOG type Moving distance

24 15

0 0 Continuous

0 1 Incremental 0.001 mm or 0.0001"

1 0 Incremental 0.010 mm or 0.0010"

1 1 Incremental 0.100 mm or 0.0100"

Pin Servocontrolled axes Non-servocontrolled axes

10 11 (G01/G02/G03) (G00) Range

1 1 25% 25% Slow range

1 0 50% 50% Ignored

0 0 100% 100% Ignored

0 1

If "P101(8)=0" 200%

If "P101(8)=1" 0%

100% Slow range

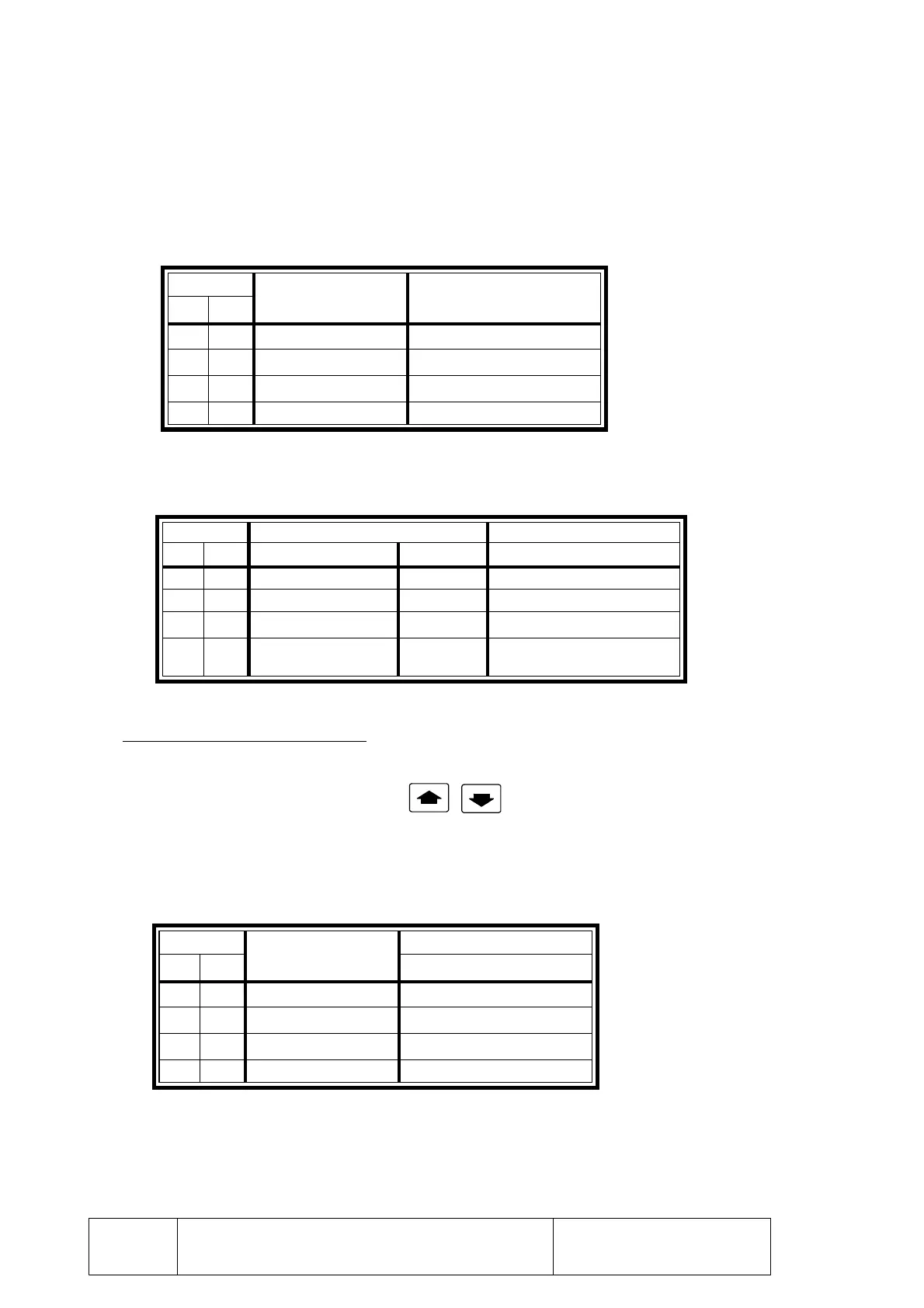

Pin

Multiplying Factor

Example: 250 lines/turn

24 15 Distance per turn

0 0 x 1 0.250 mm or 0.0250"

0 1 x 10 2.500 mm or 0.2500"

1 0 x 50 12.50 mm or 1.2500"

1 1 x 100 25.00 mm or 2.500"

When using the "JOG/handwheel 1 and 2" inputs of connector I/O2, the movements

will be either continuous or incremental and the axis will move the set distance every

time its jog key is pressed.

The table below shows the available options:

Activated pin = 1

Deactivated pin = 0

Furthermore, pins 10 and 11 of connector I/O1 allow the axis feedrate to be altered as

shown below.

Activated pin = 1, deactivated pin = 0

CNC with electronic handwheel

The positioning of axis X can either be carried out with the electronic handwheel or

from the keyboard, by using keys

Pins 15 and 24 of connector I/O2 display the multiplying factor applied by the CNC to

the pulses of the electronic handwheel.

This way, the actual axis jogging units result from multiplying the number of handwheel

pulses by this factor.

Activated pin = 1

Deactivated pin = 0

Furthermore, pins 10 and 11 of connector I/O1 allow the axis feedrate to be altered as

shown below.

Loading...

Loading...