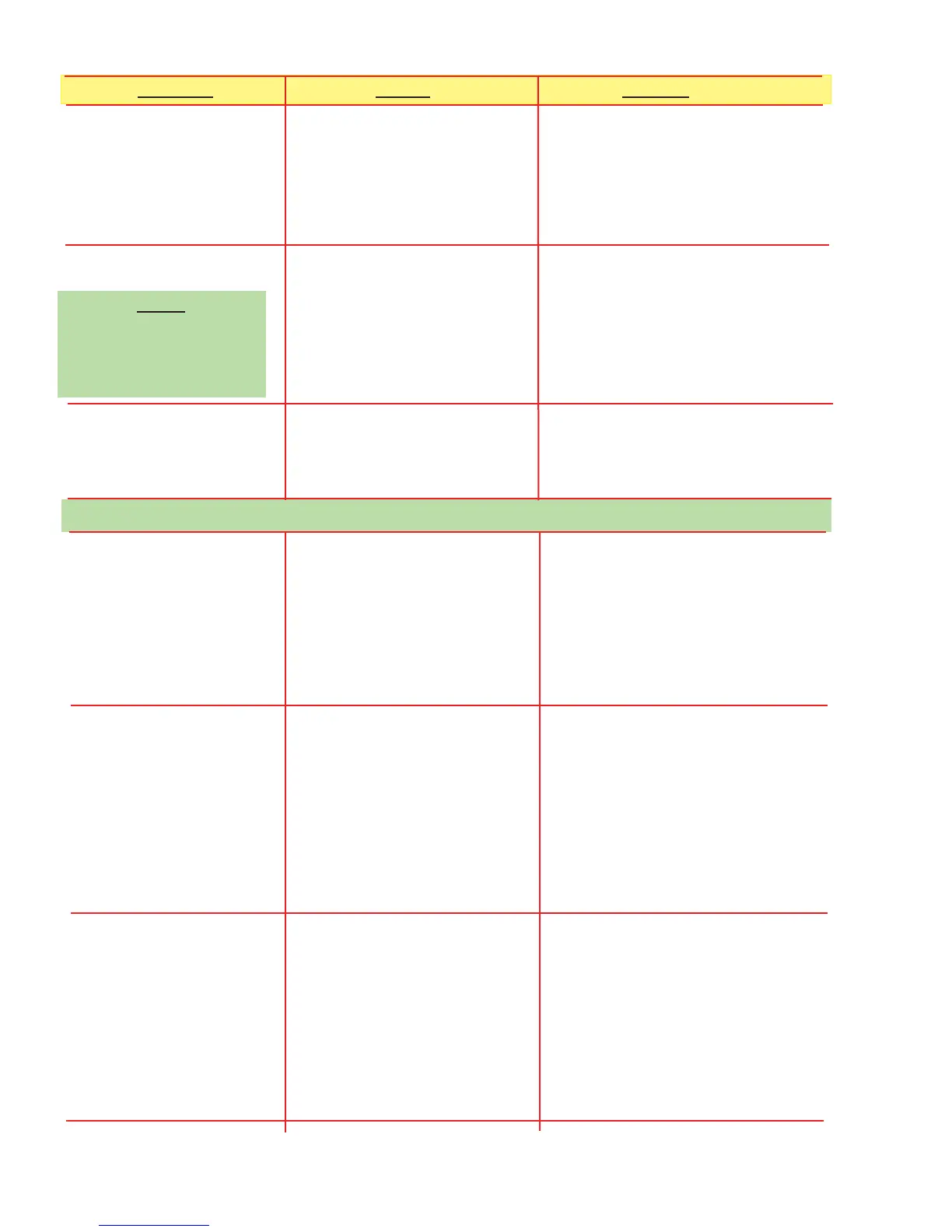

NOTE:

H2O readout will be 15-20

psi higher on the readouts.

Keep regulated pressure at

70-72 psig.

30

13.6 Brix sample valve leaks. A. Damaged or failed seal or A. Turn off CO2, water and disconnect

o-ring on valve. syrup. Depressurize by opening

sample valve. Remove clamp from

sample valve. Remove sample

valve, change o-ring and washer

and reinstall.

B. Inside of solution module is B. Replace solution module.

scratched or damaged.

13.7 Low water pressure or A. Water not turned on or line A. Turn on water. Check for line

no water pressure. restriction. restrictions.

B. CO

2 not turned on or too low. B. Assure CO2 is turned on and verify

“CO2 Press” readout is 70-72 psig.

C. Water pressure transducer C. Verify “H2O Pressure” readout at

failure. 70-72 psig. Check transducer and

replace, if needed.

D. Water pump failure. D. Check water pump and replace, if

necessary.

13.8 Noisy condenser fan. A. Fan contacting condenser, A. Remove fan guard and adjust fan

fan blade guard, or other up or down as required. Remove

part. obstruction as necessary. Reinstall

fan guard.

B. Loose fan bracket fasteners. B. Tighten loose fasteners.

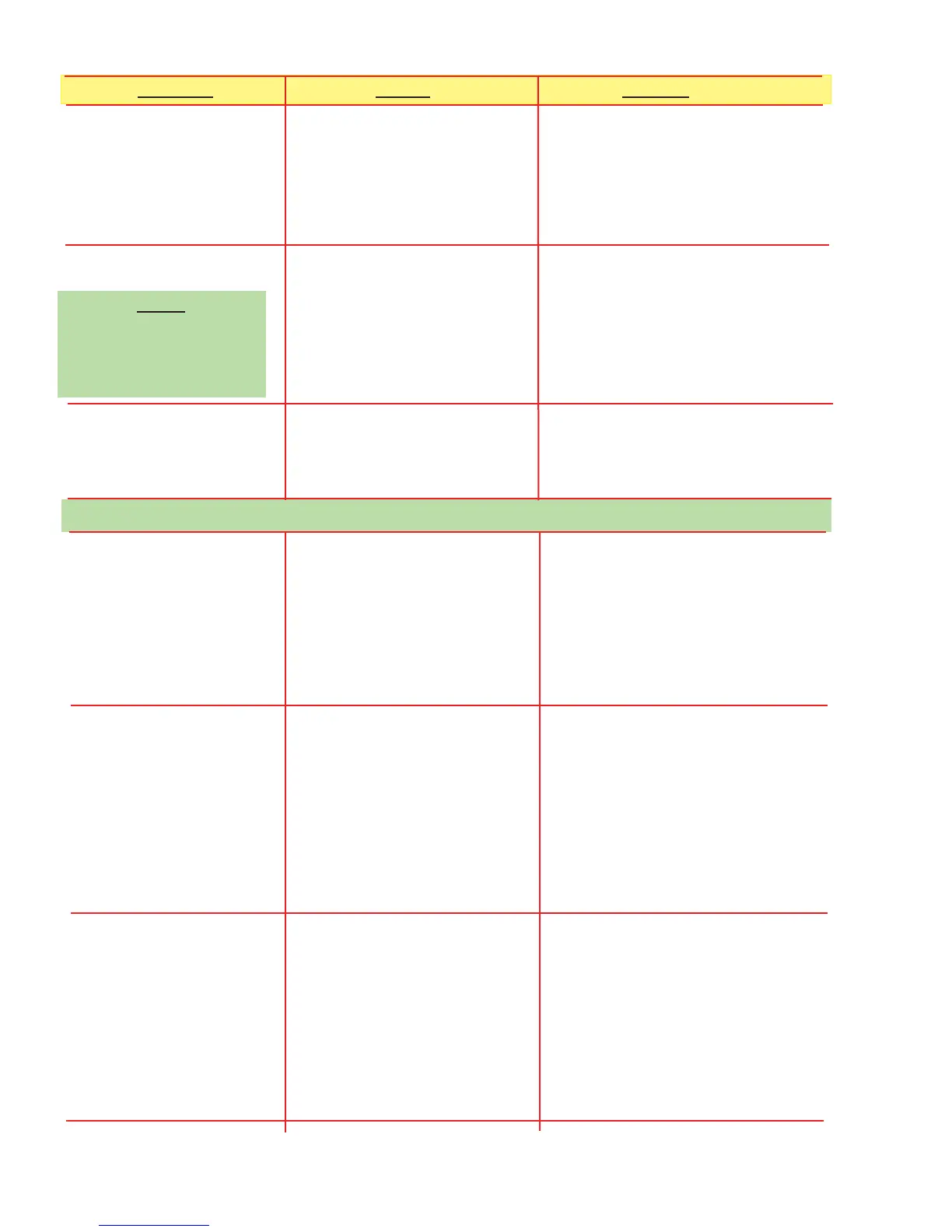

ELECTRICAL

13.9 Solenoids not activating. A. Solenoid plunger not lifting. A. In “Manual On/Off”, energize

solenoid on and off checking for

plunger movement and 24VAC at

coil. Clean or replace solenoid, if

necessary.

B. Relay Board failure. B. Test solenoid relay on Relay Board

for 24VAC output and 5VDC input.

Replace, if necessary.

C. Connectors not plugged in C. Assure connections are clean and

at board or solenoid. secure at P7, P8 and solenoid coils.

13.10 Solenoids continuously A. Solenoid plunger not dropping. A. In “Manual On/Off”, energize

activated. solenoid on and off checking for

plunger movement and 24VAC at

coil. Clean or replace solenoid, if

necessary.

B. Solenoid Relay stuck. B. Test solenoid relay on Relay Board

for 24VAC output and 5VDC relay

coil input. Replace, if necessary.

C. Transducer failure. C. Observe “Tank Pressure” readouts

and check corresponding

transducer. Replace transducer, if

necessary.

13.11 Line voltage low A. Low voltage to unit (below A. Check voltage at L1 & L2 of

on LCD. 215 volts). contactor and at wall receptacle.

Install Buck/Boost transformer, if

necessary (see Section 4).

B. Incorrect voltage offset. B. Access “Machine Settings” menu

and adjust voltage offset so “Line

Voltage” readout equals L1 and

L2 contactor voltage (see

Section 6.1).

C. Voltage Offset transformer C. Check CTRL_P6 on upper board

problem. for 24VAC. Replace transformer,

if necessary.

TROUBLE CAUSE REMEDY

Loading...

Loading...