37

TECHNICAL DATA - BASE VERSION (VB)

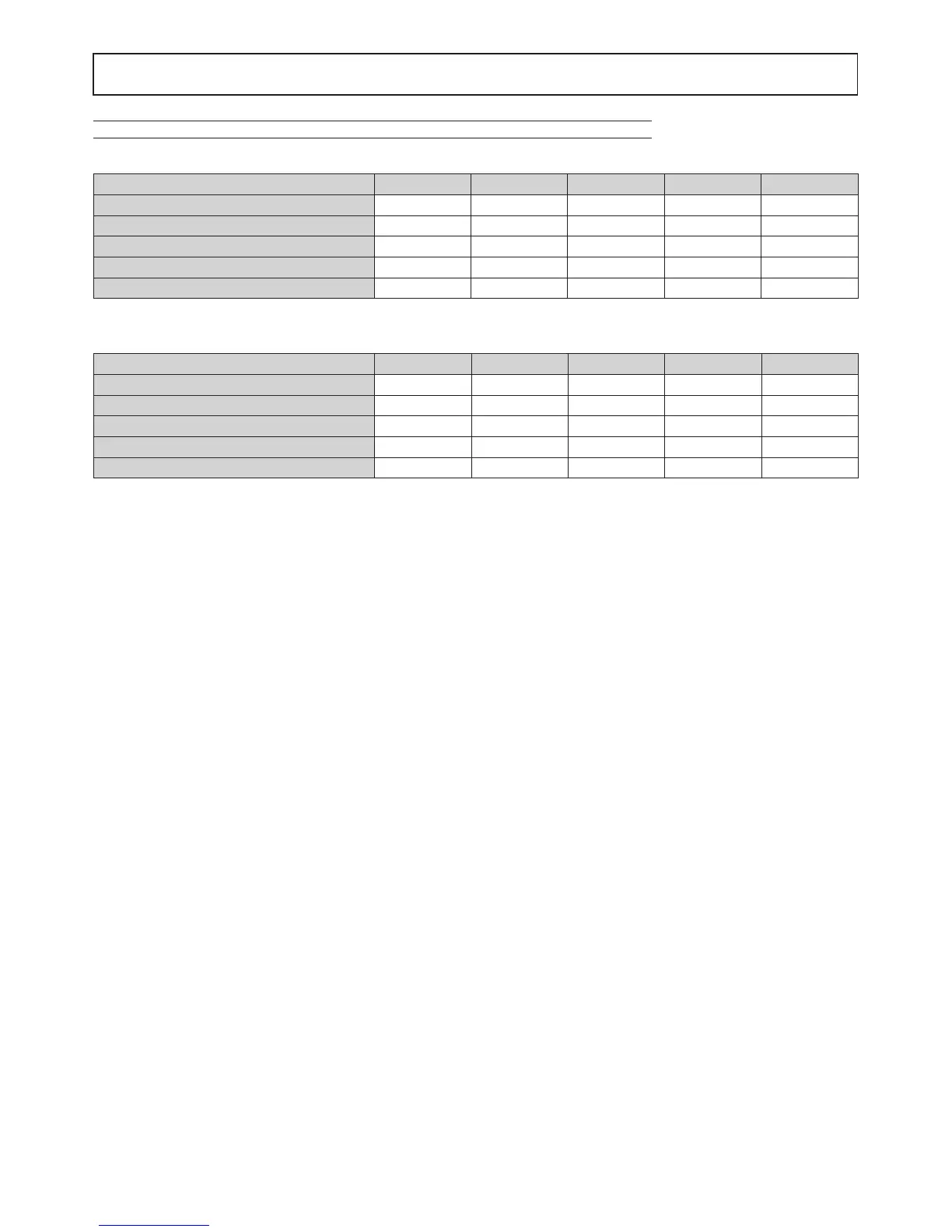

Correction factor for the use of glycol in heating mode

ETHYLENE GLYCOL with water produced between 30 ÷ 55 º C.

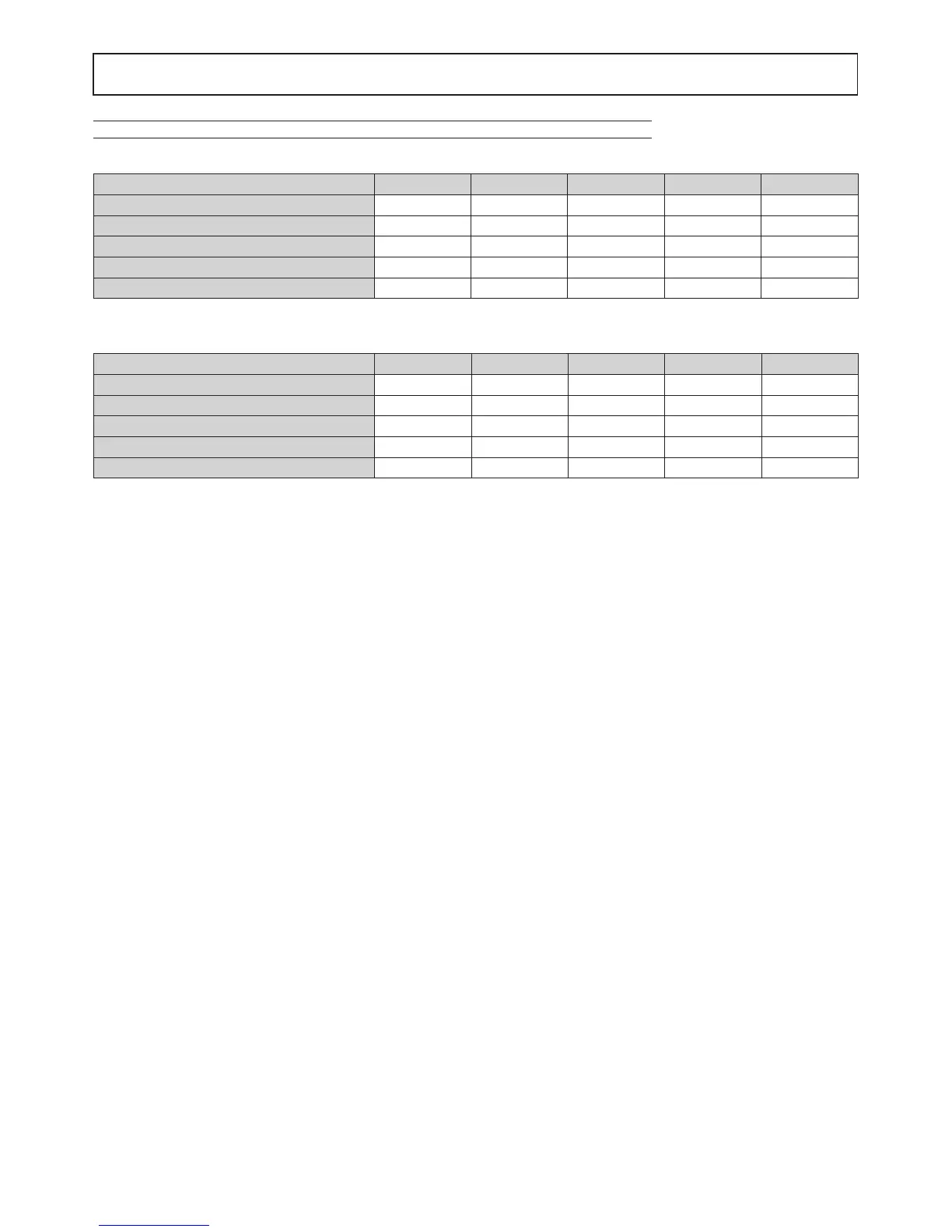

PROPYLENE GLYCOL with water produced between 30 ÷ 55ºC.

Percentage Of glycol in mass / volume 0 / 0 10 / 8,9 20 / 18,1 30 / 27,7 40 / 37,5

Freezing point [°C] 0 -3,2 -8 -14 -22

CCPT - Heating capacity 1,000 0,995 0,985 0,975 0,970

CCPA - Power input 1,000 1,010 1,015 1,020 1,030

CCQA - Water flow rate 1,000 1,038 1,062 1,091 1,127

CCDP - Water pressure drop 1,000 1,026 1,051 1,077 1,103

Percentage Of glycol in mass / volume 0 / 0 10 / 9,6 20 / 19,4 30 / 29,4 40 / 39,6

Freezing point [°C] 0 -3,3 -7 -13 -21

CCPT - Heating capacity 1,000 0,990 0,975 0,965 0,955

CCPA - Power input 1,000 1,010 1,020 1,030 1,040

CCQA - Water flow rate 1,000 1,018 1,032 1,053 1,082

CCDP - Water pressure drop 1,000 1,026 1,051 1,077 1,103

Based on DESIGN CONDITIONS from the table “performances” extract Heating Capacity (kWt

r

).

Based on type and percentage of glycol extract CCPT, CCQA, CCDP.

Then calculate.

Pt_brine=kWt

r

xCCPT

Pass_CP_brine=kWaxCCPA

Then calculate brine ow rate to the heat recovery exchanger:

Q_brine[l/s]=CCQAx(Pt_brine[kW]*0.86/∆T_brine)/3.6

where ∆T_brine is the temperature difference outlet-intlet heat recovery exchanger:

∆T_brine=Twout_brine-Twin_brine

With this brine ow rate enter in abscissa on the water pressure drop of the heat recovery then you have Dp_app.

Finally you can calculate the actual pressure drop of the brine on heat recovery:

Dp_brine=CCDPxDp_app

Loading...

Loading...