39

TECHNICAL DATA - BR - BP UNIT

Correction factors to apply to the basic version data.

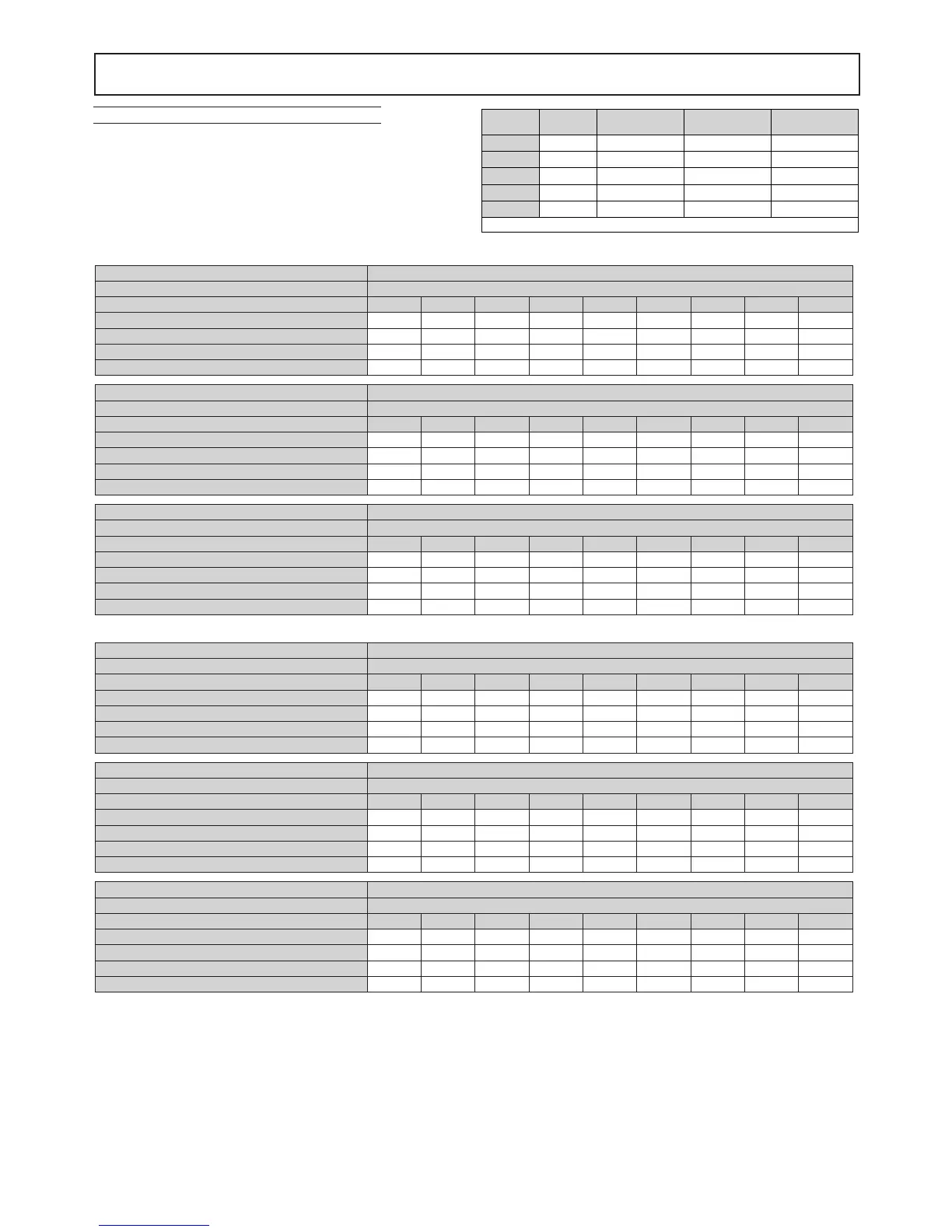

ETHYLENE GLYCOL

PROPYLENE GLYCOL

Percentage Of glycol in mass / volume 20 / 18,1

Freezing point [°C] -8

Produced water temperature 4 2 0 -2 -4 -6 -8 -10 -12

CCPF - Cooling capacity 0,912 0,855 0,798 0,738 0,683 - - - -

CCPA - Power input 0,967 0,957 0,947 0,927 0,897 - - - -

CCQA - Water flow rate 1,071 1,072 1,073 1,075 1,076 - - - -

CCDP - Pressure drop 1,090 1,095 1,100 1,110 1,120 - - - -

Percentage Of glycol in mass / volume 30 / 27,7

Freezing point [°C] -14

Produced water temperature 4 2 0 -2 -4 -6 -8 -10 -12

CCPF - Cooling capacity 0,899 0,842 0,785 0,725 0,670 0,613 0,562 - -

CCPA - Power input 0,960 0,950 0,940 0,920 0,890 0,870 0,840 - -

CCQA - Water flow rate 1,106 1,107 1,108 1,109 1,110 1,111 1,112 - -

CCDP - Pressure drop 1,140 1,145 1,150 1,155 1,160 1,175 1,190 - -

Percentage Of glycol in mass / volume 40 / 37,5

Freezing point [°C] -22

Produced water temperature 4 2 0 -2 -4 -6 -8 -10 -12

CCPF - Cooling capacity 0,884 0,827 0,770 0,710 0,655 0,598 0,547 0,490 0,437

CCPA - Power input 0,880 0,870 0,860 0,840 0,810 0,790 0,760 0,724 0,686

CCQA - Water flow rate 1,150 1,151 1,153 1,154 1,155 1,157 1,158 1,159 1,161

CCDP - Pressure drop 1,190 1,195 1,200 1,210 1,220 1,235 1,250 1,269 1,290

Percentage Of glycol in mass / volume 20 / 19,4

Freezing point [°C] -7

Produced water temperature 4 2 0 -2 -4 -6 -8 -10 -12

CCPF - Cooling capacity 0,874 0,807 0,740 0,690 0,641 - - - -

CCPA - Power input 0,945 0,935 0,925 0,900 0,875 - - - -

CCQA - Water flow rate 1,037 1,038 1,039 1,039 1,040 - - - -

CCDP - Pressure drop 1,110 1,115 1,120 1,130 1,140 - - - -

Percentage Of glycol in mass / volume 30 / 29,4

Freezing point [°C] -13

Produced water temperature 4 2 0 -2 -4 -6 -8 -10 -12

CCPF - Cooling capacity 0,869 0,799 0,729 0,680 0,630 0,583 0,536 - -

CCPA - Power input 0,935 0,923 0,910 0,888 0,865 0,838 0,810 - -

CCQA - Water flow rate 1,072 1,071 1,070 1,069 1,069 1,068 1,067 - -

CCDP - Pressure drop 1,160 1,175 1,190 1,200 1,210 1,255 1,300 - -

Percentage Of glycol in mass / volume 40 / 39,6

Freezing point [°C] -21

Produced water temperature 4 2 0 -2 -4 -6 -8 -10 -12

CCPF - Cooling capacity 0,848 0,784 0,719 0,670 0,620 0,570 0,520 0,478 0,438

CCPA - Power input 0,865 0,855 0,845 0,820 0,795 0,773 0,750 0,714 0,680

CCQA - Water flow rate 1,116 1,114 1,112 1,110 1,108 1,107 1,105 1,103 1,101

CCDP - Pressure drop 1,230 1,275 1,320 1,375 1,430 1,500 1,570 1,642 1,724

Based on leaving water temperature of the evaporator and condensing temperature = 7°C from the table “performances” extract Cooling Capacity

(kWf) and Compressors Power Input (kWa).

Based on type and percentage of glycol extract CCPF, CCPA, CCQA, CCDP.

Then calculate.

Pf_brine=kWfxCCPF

Pass_CP_brine=kWaxCCPA

Then calculate brine flow rate:

Q_brine_evap[l/s]=CCQAx(Pf_brine[kW]*0.86/∆T_brine)/3.6

where ∆T_brine is the difference between inlet-outlet evaporator water temperature:

∆T_brine=Twin_evap_brine-Twout_evap_brine

With this brine flow rate enter in abscissa on the water pressure drop of the evaporator then you have Dp_app.

Finally you can calculate the actual pressure drop of the brine on evaporator side:

Dp_evap_brine=CCDPxDp_app

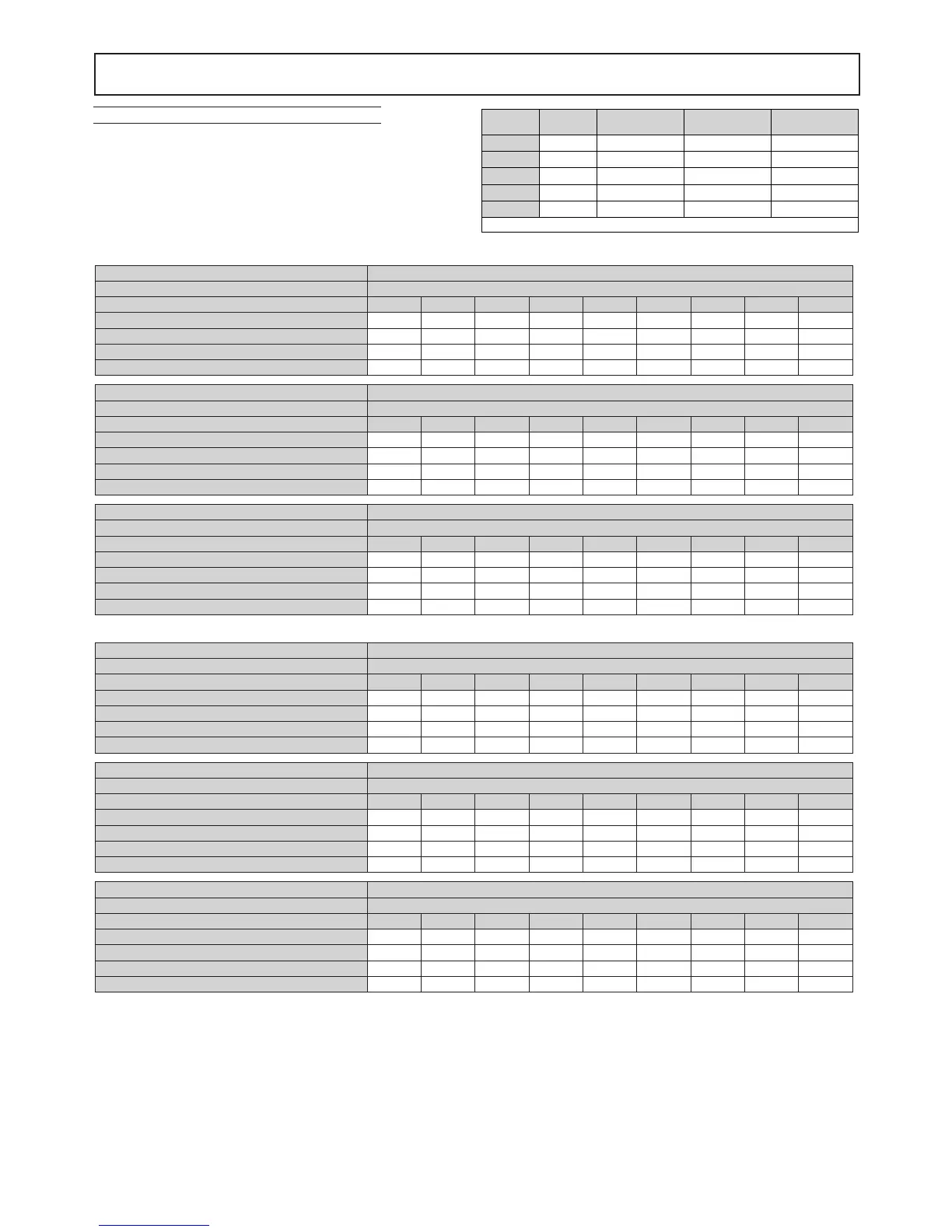

Mandatory requirements for BR and BP units

Parameter

to set

Default

value

How to calculate

the value to set

Example

with TWE = 0°C

Example

with TWE = -5°C

AL51 3 °C TWE -4 °C -4 °C -9 °C

TR10 9 °C TWE +2 °C +2 °C -3 °C

TR11 7 °C TWE +2 °C +2 °C -3 °C

HI12 4 °C TWE -3 °C -3 °C -8 °C

HI14 4 °C TWE -3 °C -3 °C -8 °C

TWE= Evaporator outlet desired water temperature

BR and BP units must be used with a mixture of water and antifre-

eze fluid (eg glycol) in a percentage enought to prevent freezing

of the mixture under all possible conditions, otherwise it will VOID

THE WARRANTY.

Please contact our customer service to set the following parame-

ters: →

Loading...

Loading...