4 Commissioning

32 Festo – GDCP-CMMS-AS-G2-S1-EN – 1306NH – English

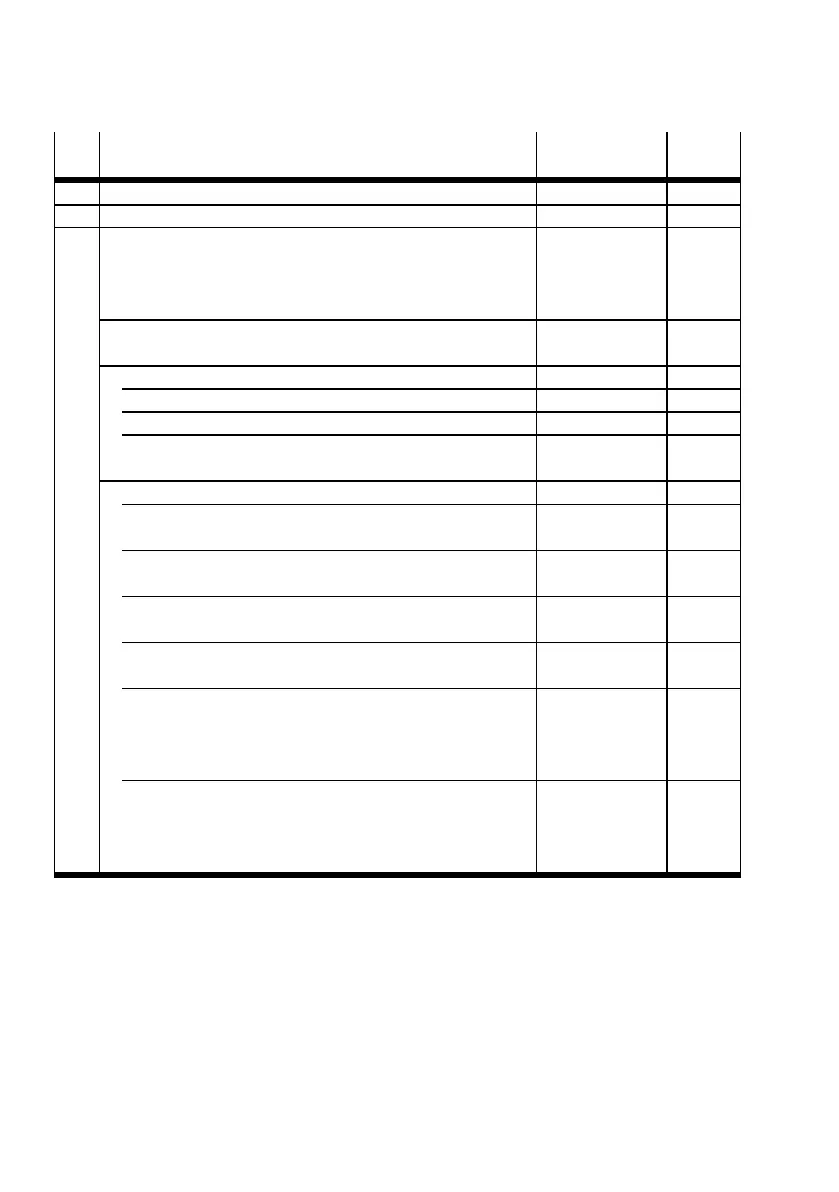

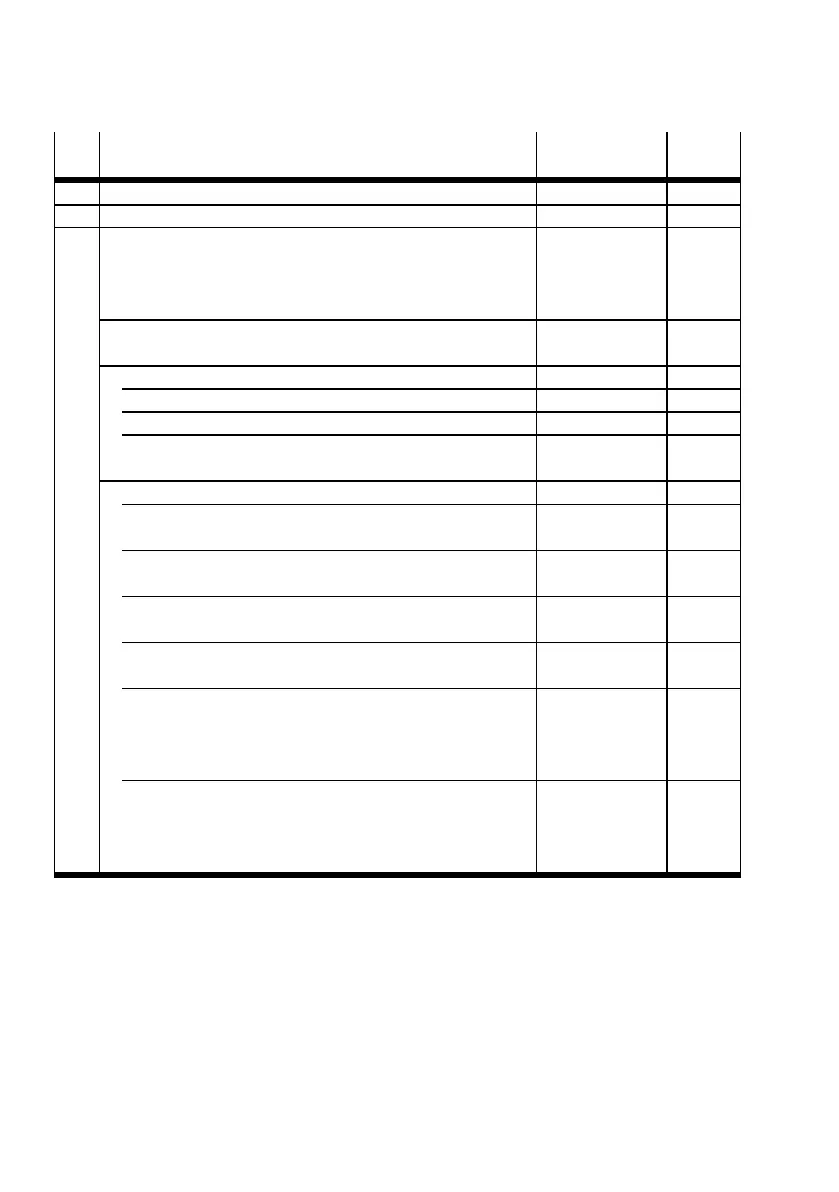

No. Questions Applicable Com-

pleted

1. Has a risk assessment been conducted? Yes 0 No 0 0

2. Have an error list and a validation plan been drawn up? Yes 0 No 0 0

3. Was the validation plan, including analysis and inspection,

processed and a validation report compiled?

The validation procedure must include the following

inspections as a minimum:

Yes 0 No 0 0

a) Inspection of c omponents: Is a CMMS-AS-...-G2 used

(inspection using the rating pla tes)

Yes 0 No 0 0

b) Is the wiring correct (check against the wiring diagram)? Yes 0 No 0 0

Have any short-circuit bridges been removed? Yes 0 No 0 0

Has a safety switching device been wired to X1 and X3? Yes 0 No 0 0

Is the safety switch device certified and wired in accordance

with the application's requirements?

Yes 0 No 0 0

c) Functional tests: Yes 0 No 0 0

Pressing the emergency stop button on the unit. Is the drive

switched free of torque?

Yes 0 No 0 0

If only Rel (X3.2) is activated – is the drive switched

torque-free immediately?

Yes 0 No 0 0

If only DI N4 ( X1.21) is activated – is the drive switched

torque-free immediately?

Yes 0 No 0 0

Has a short circuit been detected between Rel ( X3.2) and

DIN4 (X1.21) or is a suitable fault exclusion defined?

Yes 0 No 0 0

Check of the safety switching device with evaluation of the

acknowledgment contact NC1/NC2:

Is the drive switched torque-free if there is a short circuit

fromNC1toNC2?

Yes 0 No 0 0

Is a restart inhibited? That is, no movement occurs when the

emergency stop button is pressed and the enable signals

are active unless a start c ommand is ac knowledged

beforehand.

Yes 0 No 0 0

Tab. 4.2 Questions for validation in accordance with EN ISO 13849-1 and -2 (example)

Loading...

Loading...