12

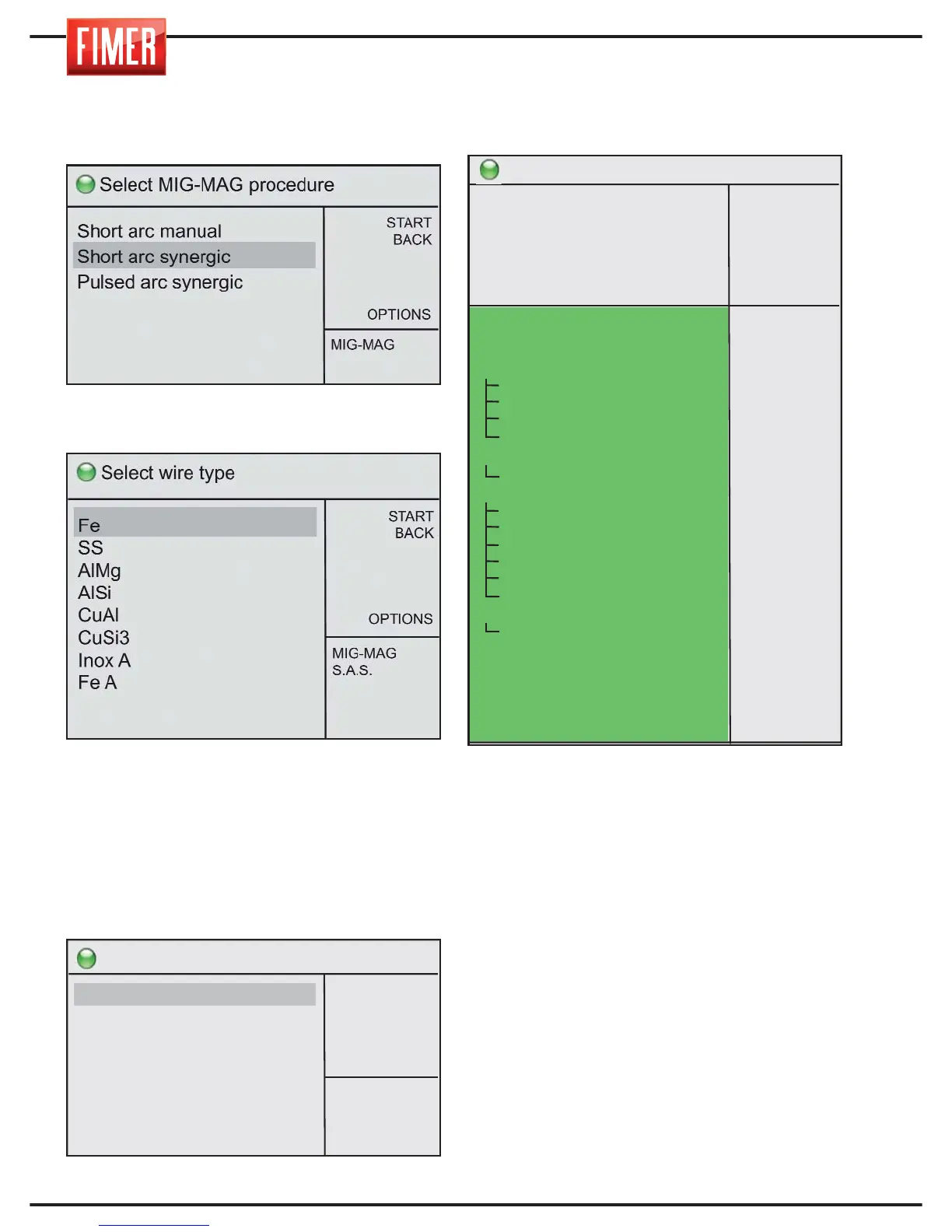

Turn switch 10 to choose from the different

MIG-MAG welding options; press the switch

again to confirm the chosen option.

Once selected, the screen with the welding

wire material options will appear:

Settings that do not appear on the screen

are accessible by turning switch 10.

Once the type of wire has been selected

(using switch 10), the settings page for the

welding wire diameter will appear.

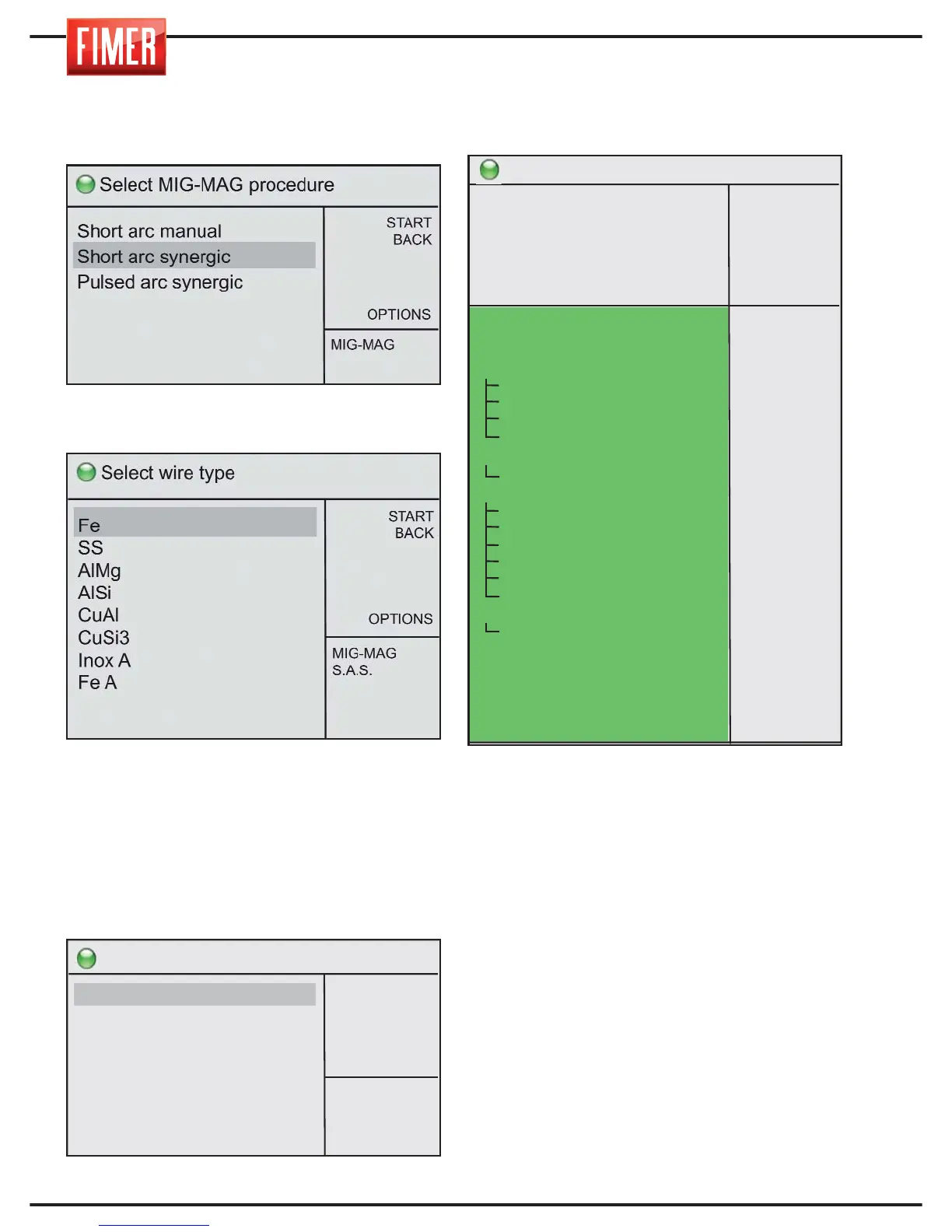

Selecting this option will take you to the

welding screen:

ADJUSTMENTS AND SETTINGS:

Button 10 adjusts the welding settings on the

screen:

Arc length: Used to vary the basic voltage

used for welding.

Deposit: Used to modify the deposit of filler

material (wire speed) compared to the

predetermined synergic value.

Inductance: Used to modify the speed of

variation of the welding current to obtain a

harder arc (low values) or softer arc (high

values.

Double short: Used to activate (ON) or

Loading...

Loading...