23

ESPAÑOL FRANÇAIS

DEUTSCH

ENGLISH

ITALIANO

14. CONNECTOR FOR TIG WELDING

1) Connect the earth cable to the appropriate

‘+’ socket on the front of the device (14 of fig.1).

Insert by lining-up the key with the groove

and turn in a clockwise direction until it stops.

Do not fasten too tightly!

2) Connect the torch to the appropriate ‘-‘

socket on the front of the device (12 of fig 1).

3) Insert by lining-up the key with the groove

and turn in a clockwise direction until it stops.

Do not fasten too tightly!

4) Insert the torch pulse signal connector into

the socket

TIG WELDING:

Before connecting the gas make sure the

cylinder contains Inert gas. Never use any

other type of gas.

Connect the pres-

sure regulator to the

cylinder, after whi-

ch, connect the lat-

ter to the gas tube

of the torch.

TIG welding is usual-

ly carried out with a

constant current, with

a negative pole (‘-‘

see fig.6).

The cable of the TIG torch is then inserted

into the negative socket (12of fig.1), whilst

the earth cable of the workpiece is connec-

ted to the positive socket. (14 of fig.1).

At this stage it is possible to adjust the welding

current using the potentiometer (9 of fig. 1) on

the front panel.

The diameter of the electrode and the wel-

ding current settings must be selected accor-

ding to the characteristics of the material

to be welded.

15. POWER CONNECTOR

Before connecting the machine check the

tension, number of phases and the power

supply frequency. The admissible power

supply is indicated on the information plate

on the machine.

Check that the earth of the welder has been

connected correctly. Furthermore, make sure

that the plug provided with the equipment is

compatible with the local grid sockets. Make

sure that the power supply provides sufficient

power for the machine to function (tension

ranges).

The machine is provided with a specific

power cable that does not usually require an

extension lead; in the event an extension

lead is required, use one of the same

capacity or higher than the machine in use,

according to the length of the cable. A 2.5

mm² three-pole cable + earth, of the same

size or larger.

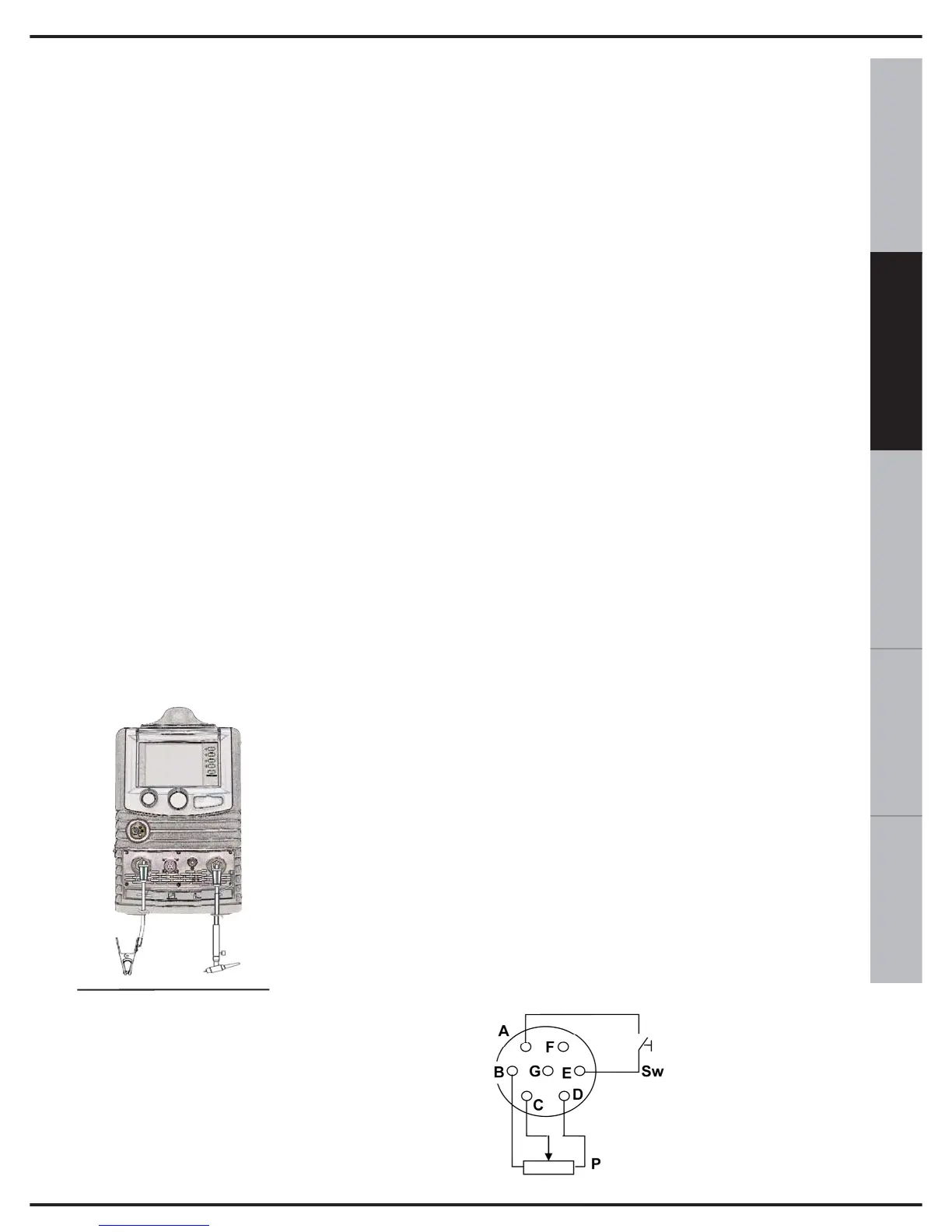

16. REMOTE CONNECTION

Figure 7 shows the connections of the

remote connector (13 of fig 1).

Where:

Sw is the torch

trigger

P is the potentiometer

for controlling the

current.

Fig.6

Fig.7

Loading...

Loading...