ET Valve

Instruction Manual

Form 5081

June 2002

2

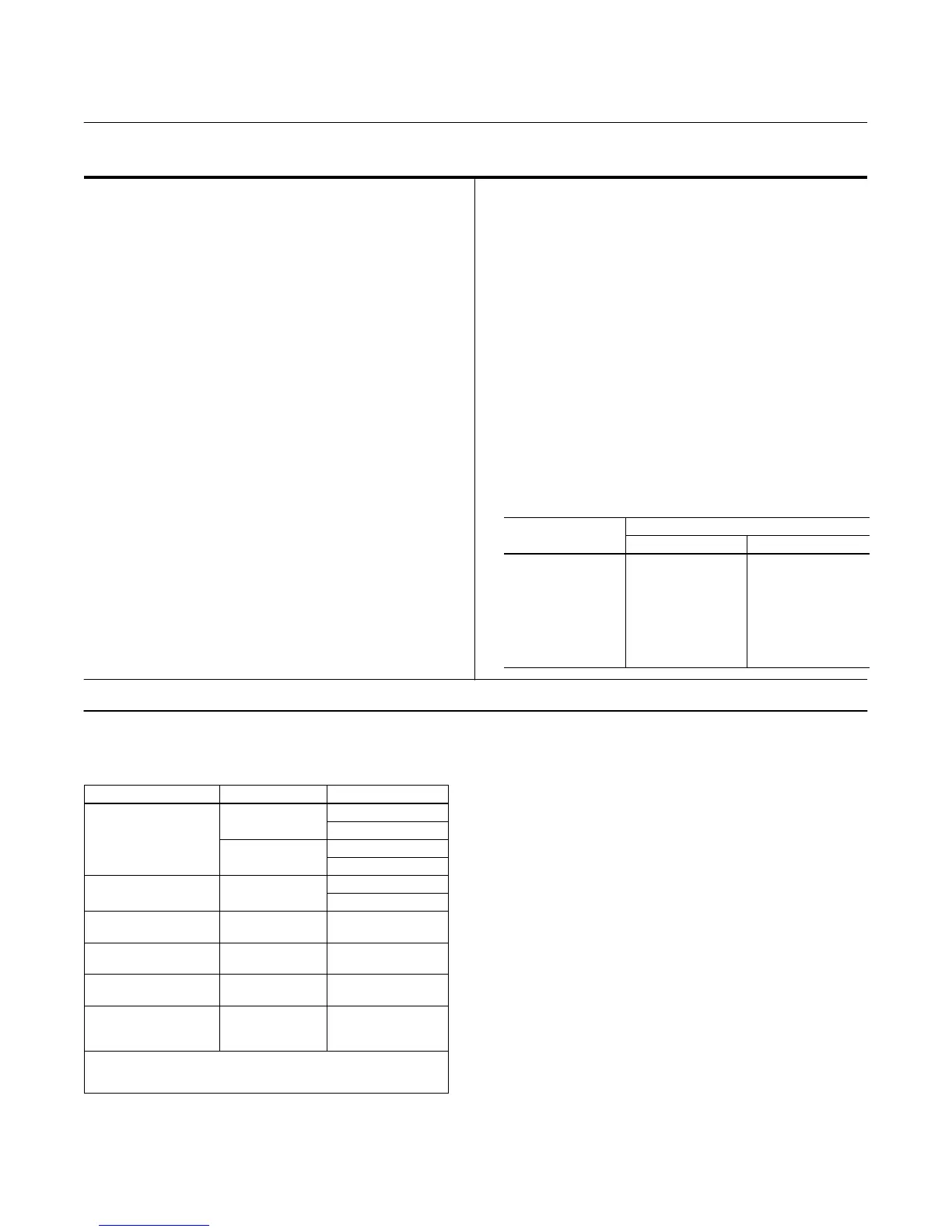

Table 1. Specifications

End Connection Styles

Cast Iron Valves

Flanged: Class 125 flat-face or 250 raised-face

flanges per ASME B16.1

Screwed: Consistent with ASME B16.4

Steel and Stainless Steel Valves

Flanged: Class 150, 300, and 600 raised-face or

ring-type joint flanges per ASME B16.5

Screwed or Socket Welding: All available ASME

B16.11 schedules that are consistent with Class

600 per ASME B16.34

Buttwelding: Consistent with ASME B16.25

Maximum Inlet Pressure

(1)

Cast Iron Valves

Flanged: Consistent with Class 125B or 250B

pressure-temperature ratings per ASME B16.1

Screwed: Consistent with Class 250

pressure-temperature ratings per ASME B16.4

Steel and Stainless Steel Valves

Flanged: Consistent with Class 150, 300, and 600

pressure-temperature ratings per ASME B16.34

Screwed or Welding: Consistent with Class 600

pressure-temperature ratings per ASME B16.34

Shutoff Classifications

See table 2

Flow Characteristics

Linear (all cages), quick-opening (all except

Whisper Trim

, WhisperFlo

, and Cavitrol

cages), or equal percentage (all except Whisper

Trim, WhisperFlo, and Cavitrol cages)

Flow Directions

Linear, Quick Opening, or Equal Percentage

Cage: Normally down

Whisper Trim and WhisperFlo Cages: Always

up

Cavitrol Cage: Always down

Approximate Weights

VALVE SIZE,

WEIGHT

VALVE SIZE,

INCHES

kg

Pounds

1 & 1-1/4

1-1/2

2

2-1/2

3

4

6

8

14

20

39

45

54

77

159

408

30

45

67

100

125

170

350

900

1. The pressure/temperature limits in this manual and any applicable standard or code limitation for valve should not be exceeded.

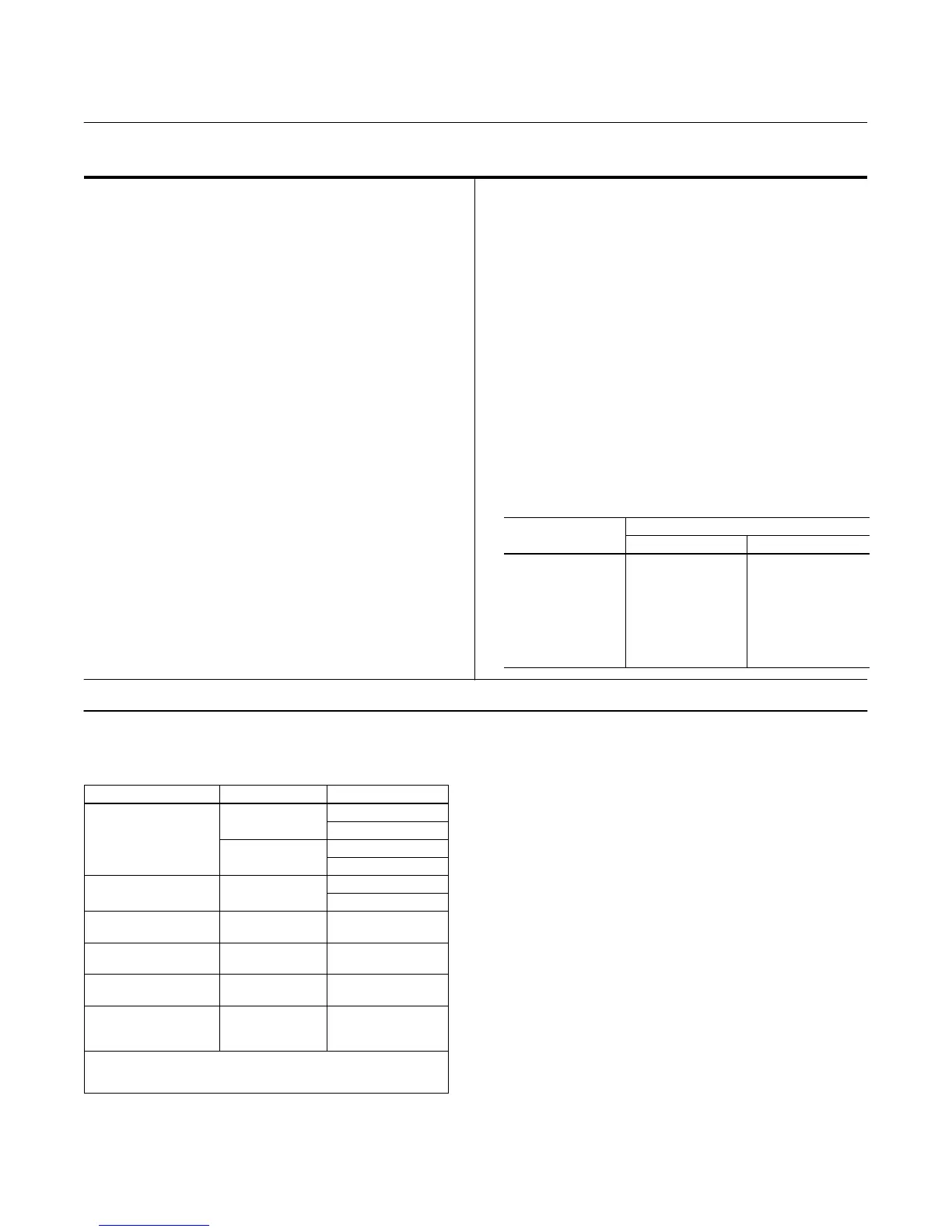

Table 2. Available Shutoff Classifications per

ANSI/FCI 70-2 and IEC 60534-4

Valve Design Seating Shutoff Class

Standard air test

(1)

All except those with

PTFE (standard)

V (optional)

All except those with

Cavitrol III cages

IV

Metal

V (optional)

(2)

ET with Cavitrol III

IV (standard)

ET with Cavitrol III

one-stage cage

Metal

V (optional)

ET with Cavitrol III

two-stage cages

Metal V

ET w/PEEK

Anti-Extrusion Rings

Metal

V to 316C (600F)

ET w/

3-7/16 to 7-inch port

Soft or Metal VI

ET and EAT

w/ TSO

(Tight Shutoff Trim)

Replaceable,

protected soft

seat

TSO

(1)

1. This is a special non-ANSI/FCI leakage class.

2. Class V shutoff requires spring-loaded seal ring, radiused-seat plug, and

wide-bevel seat ring (not available with 8-inch port, quick-opening cage). Not

available with trims 4, 29, and 85.

Description

These single-port valves have cage guiding,

quick-change trim, and balanced

push-down-to-close valve plug action. Valve

configurations are as follows:

Design ET—Globe-style valve (figure 1) with

metal-to-PTFE seating (standard for all except

Cavitrol III cages) for stringent shutoff requirements,

or metal-to-metal seating (standard for Cavitrol III

cages, optional for all others) for higher

temperatures.

Design EAT—Angle version of Design ET, used to

facilitate piping or in applications which require a

self-draining valve.

Loading...

Loading...