ET Valve

Instruction Manual

Form 5081

June 2002

7

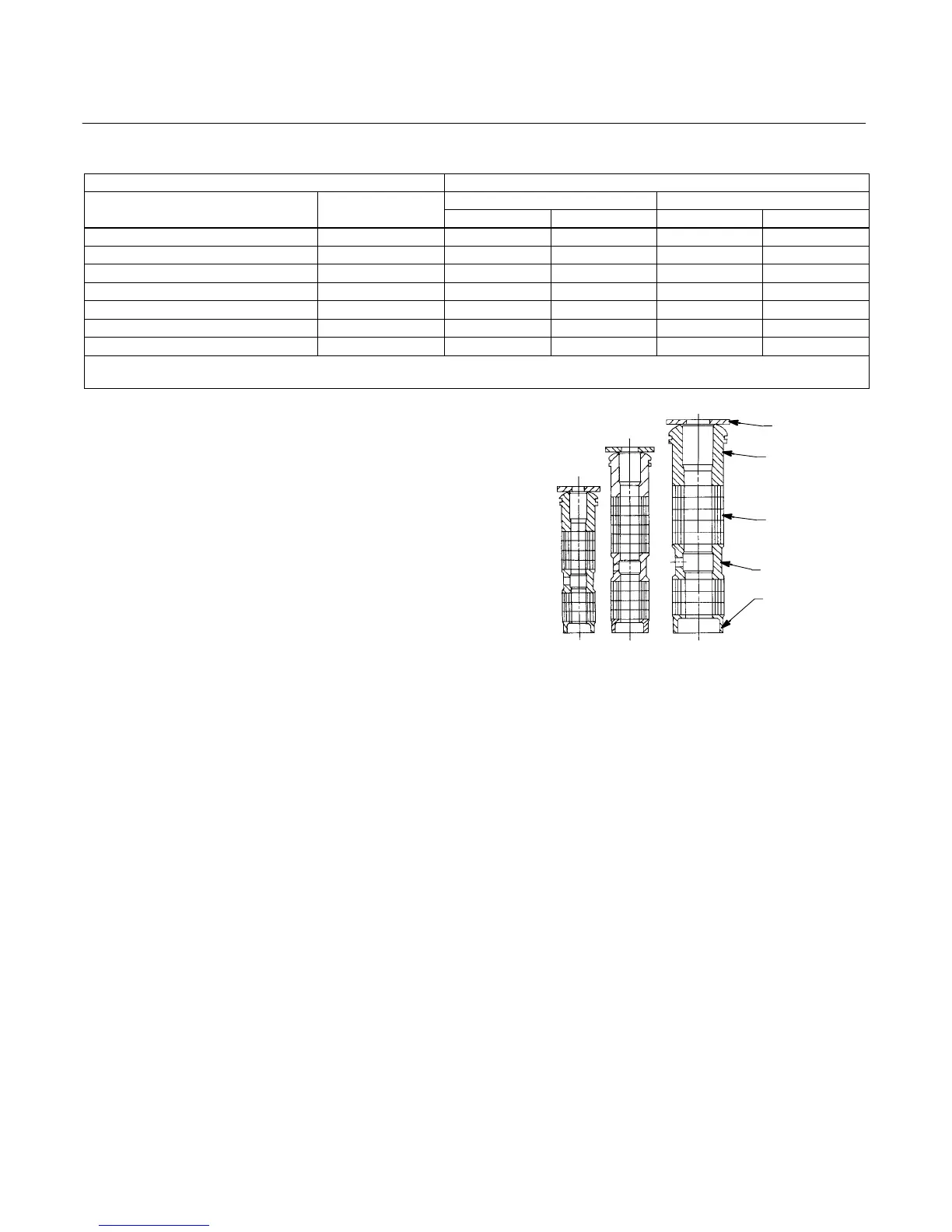

Table 3. Body-to-Bonnet Bolt Torque Guidelines

VALVE SIZE, INCHES BOLT TORQUES

(1)

SA193-B7, SA193-B8M

(3)

SA193-B8M

(2)

Design ET Design EAT

Nm Lbfft Nm Lbfft

1-1/4 or less 1 129 95 64 47

1-1/2, 1-1/2 x 1, 2, or 2 x 1 2 or 2 x 1 96 71 45 33

2-1/2 or 2-1/2 x 1-1/2 3 or 3 x 1-1/2 129 95 64 47

3, 3 x 2, or 3 x 2-1/2 4 or 4 x 2 169 125 88 65

4, 4 x 2-1/2, or 4 x 3 6 or 6 x 2-1/2 271 200 156 115

6 ––– 549 405 366 270

8 ––– 746 550 529 390

1. Determined from laboratory tests.

2. SA193-B8M annealed.

3. SA193-B8M strain hardened.

screws completely and carefully lift the bonnet off

the valve.

5. Remove the locknut and separate the valve plug

and stem from the bonnet. Set the parts on a

protective surface to prevent damage to gasket or

seating surfaces.

6. Remove the bonnet gasket (key 10, figure 16, 17,

or 20) and cover the opening in the valve to protect

the gasket surface and prevent foreign material from

getting into the valve body cavity.

7. Remove the packing flange nuts, packing flange,

upper wiper, and packing follower (keys 5, 3, 12, and

13, figure 14). Carefully push out all the remaining

packing parts from the valve side of the bonnet using

a rounded rod or other tool that will not scratch the

packing box wall. Clean the packing box and the

metal packing parts.

8. Inspect the valve stem threads and packing box

surfaces for any sharp edges which might cut the

packing. Scratches or burrs could cause packing box

leakage or damage to the new packing. If the

surface condition cannot be improved by light

sanding, replace the damaged parts by following the

appropriate steps in the Trim Maintenance

procedure.

9. Remove the covering protecting the valve body

cavity and install a new bonnet gasket (key 10,

figure 16, 17, or 20), making sure the gasket seating

surfaces are clean and smooth. Then slide the

bonnet over the stem and onto the stud bolts (key

15, figure 16, 17, or 20) or onto the valve body cavity

if cap screws (not shown) will be used instead.

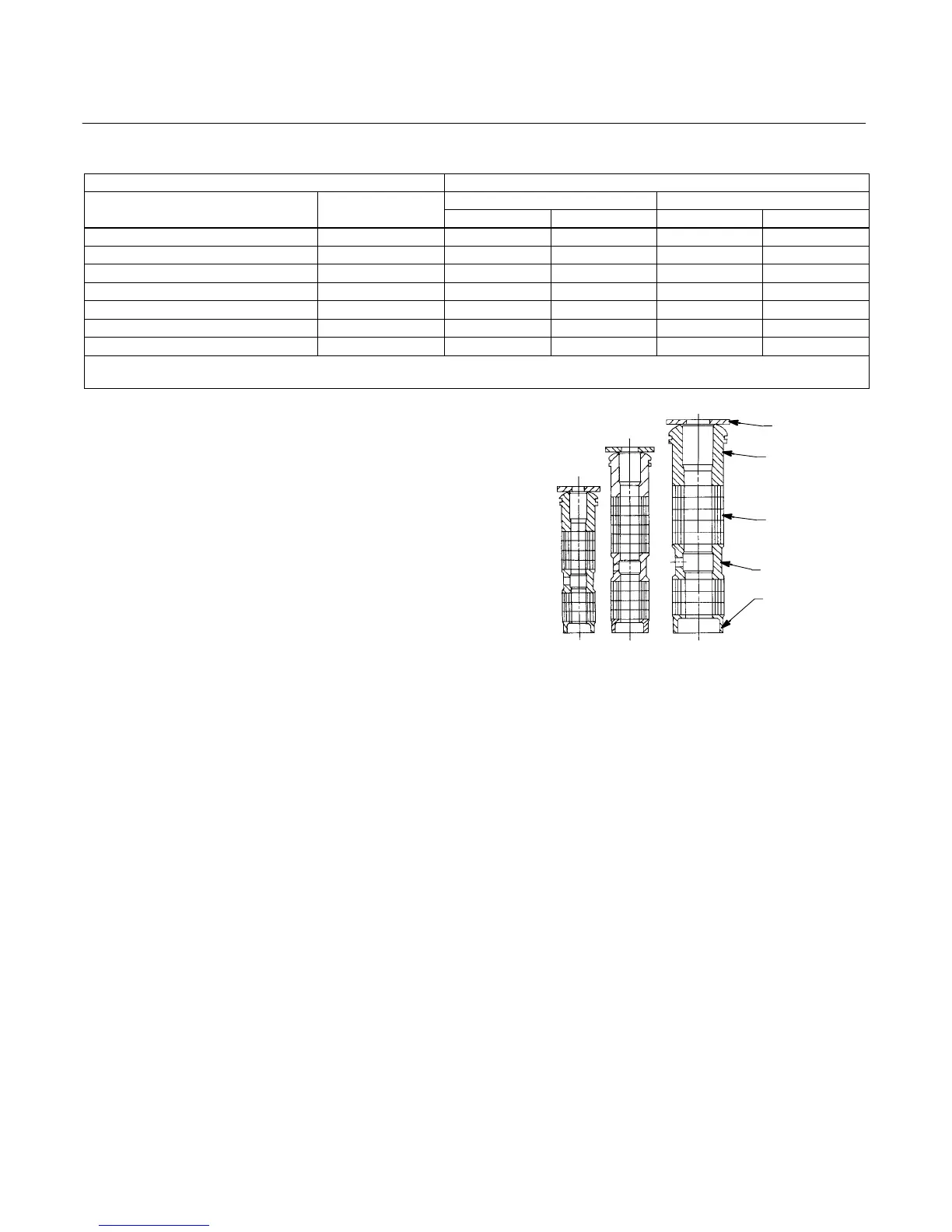

Figure 4. Detail of PTFE/Composition Packing Arrangements

for Plain and Extension Bonnets

UPPER WIPER

(KEY 12)

PACKING

FOLLOWER (KEY 13)

LANTERN RING

(KEY 8)

PACKING BOX

RING (KEY 11)

PACKING RING

(KEY 7)

9.5 mm

(3/8 INCH)

STEM

12.7 mm

(1/2 INCH)

STEM

19.1, 25.4, OR

31.8 mm

(3/4, 1, OR

1Ć1/4 INCH)

STEM

12A8188-A

12A7815-A

12A8173-A

A2619-1 / IL

Note

Proper performance of the bolting

procedures in step 10 compresses the

spiral wound gasket (key 12, figure 16

or 17) or load ring (key 26, figure 20)

enough to both load and seal the seat

ring gasket (key 13, figure 16, 17 or 20).

It also compresses the outer edge of

the bonnet gasket (key 10, figure 16

through 20) enough to seal the

body-to-bonnet joint.

The proper bolting procedures in step

10 include—but are not limited

to—ensuring that bolting threads are

clean, and evenly tightening the cap

screws, or the nuts onto the studs, in a

crisscross pattern. Tightening one cap

screw or nut may loosen an adjacent

Loading...

Loading...