Disassembling the intensifier

1. Shut down the system.

WARNING

Place the main electrical disconnect in the OFF

position and bleed down the high-pressure lines.

Place an “Out of Service” tag on the main electrical

disconnect and lock it out. Failure to do so can cause

equipment damage or injury to personnel.

2. Disconnect the high-pressure tubing from the intensi

-

fier outlet adapter and move it out of the way.

3. Disconnect the supply water hose from the end cap.

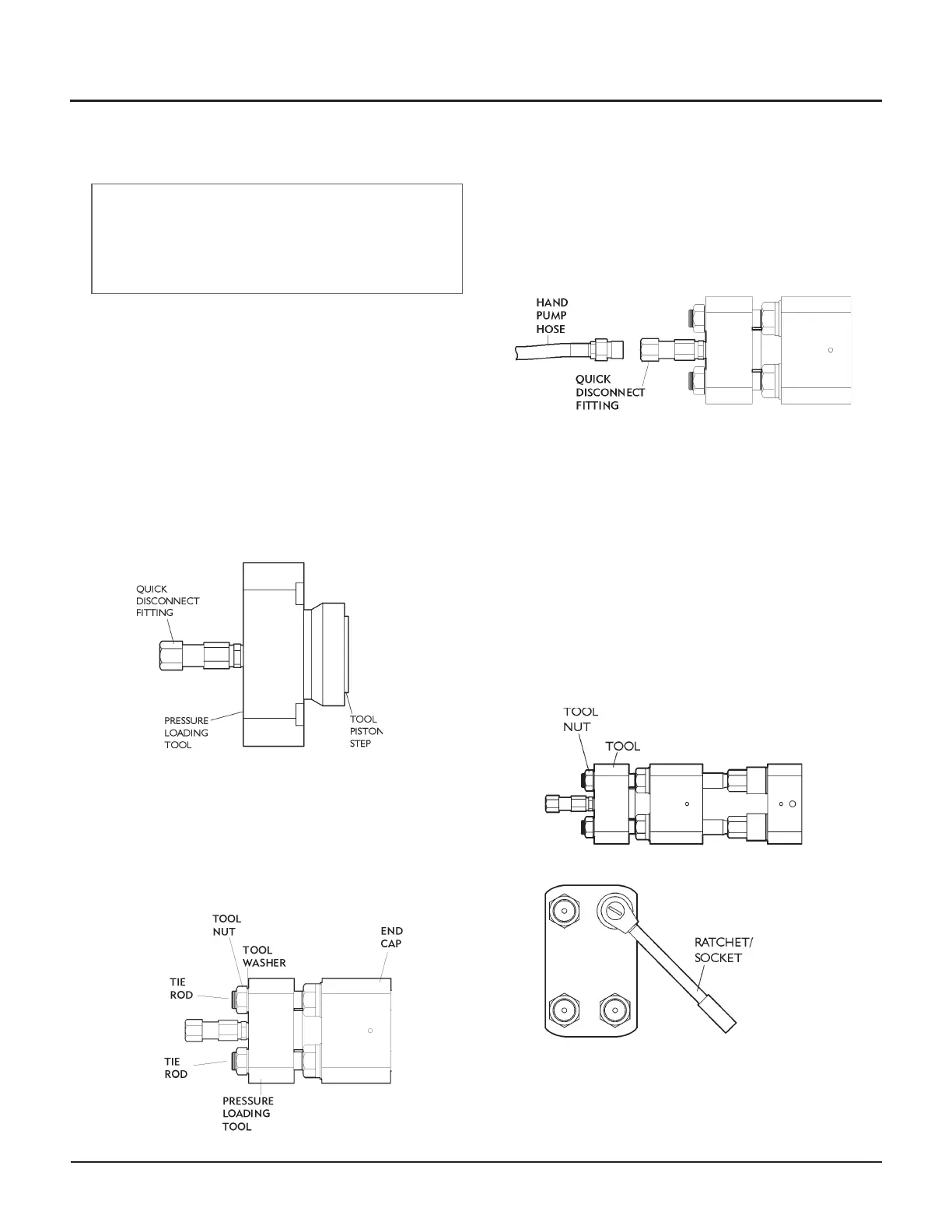

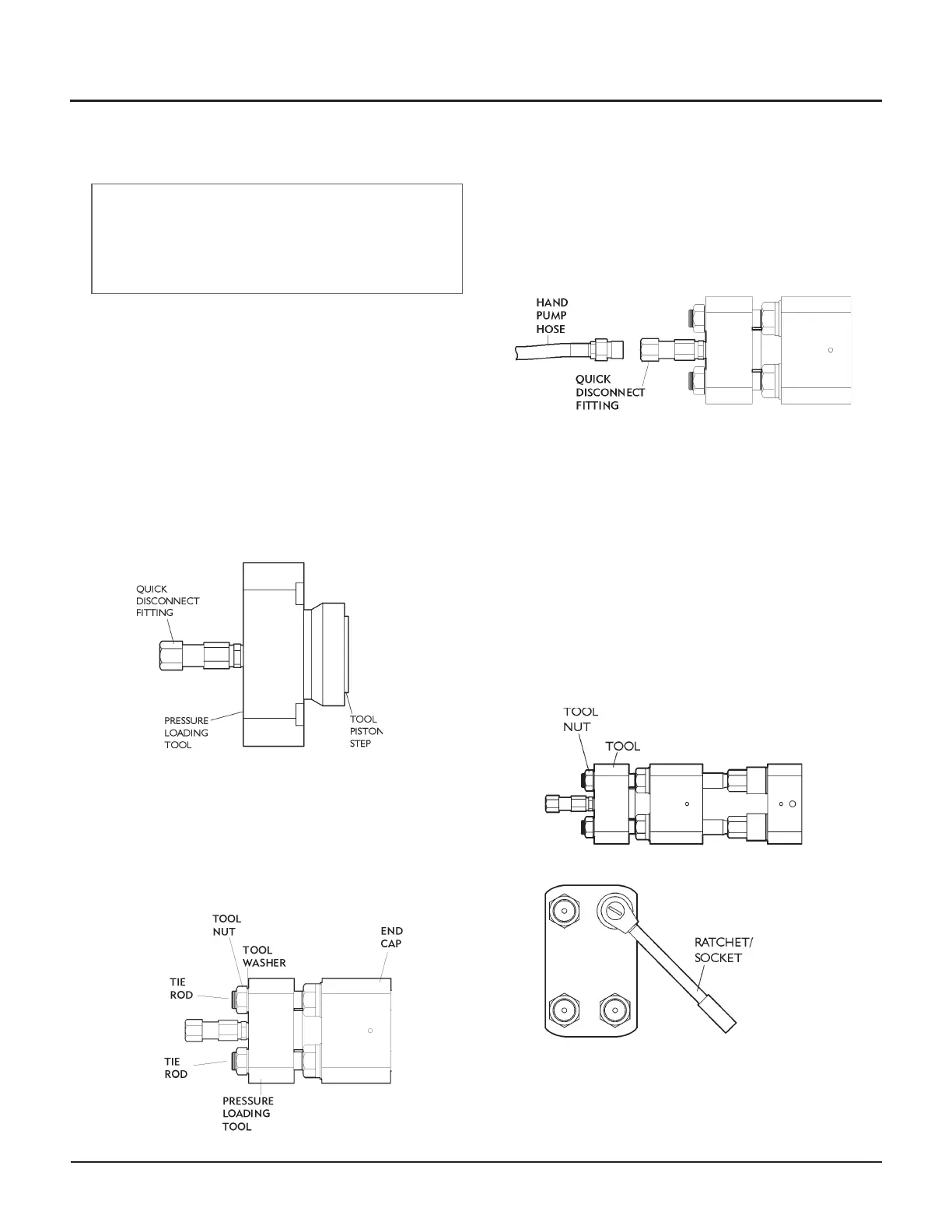

4. Install the pressure loading tool on the tie rods, being

careful to correctly locate the tool piston step in the

end cap counterbore.

CAUTION

Make sure the tool piston step is fully engaged in the

counterbore before continuing. Failure to do so can damage

the end cap or the pressure loading tool.

5. Thoroughly clean the tie rods to ensure no old

anti-seize lubricant remains. Apply fresh anti-seize to

the threads at the end of the tie rods, and on both

sides of the tool washers.

6. Install the tool washers and nuts on the tie rod ends

and run up hand tight to the tool.

7. Connect the hand pump hose to the tool at the

quick-disconnect fitting.

Note: On some tool models the hand pump hose

does not have a quick-disconnect fitting. If this is the

case, leave the hose attached to the tool at all times

to prevent leaking.

8. Open the pressure-release valve on the hand pump

by turning the valve handle counterclockwise one

turn.

9. Collapse the pressure loading tool using a ratchet

and socket on the tool nuts, tightening all of the nuts

until they are snug against the tool.

Note: Oil from the tool will flow back to the hand

pump reservoir.

© Flow International Corporation M-376 | 21

CHAPTER 3

Maintenance Procedures

Loading...

Loading...