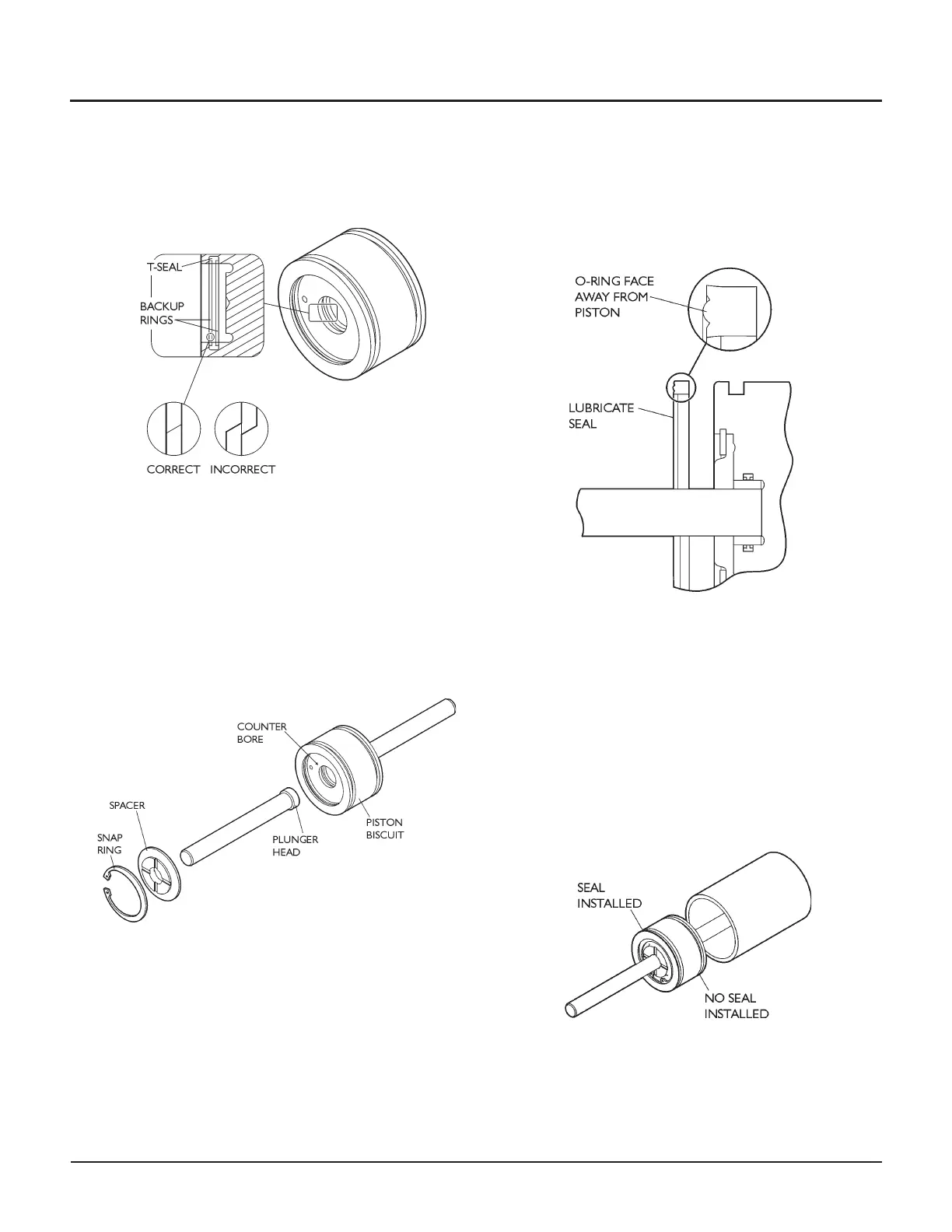

26. Lubricate the new T-seals and backup rings with

Parker O-Ring Lube (200006). Place two backup

rings and one T-seal in each piston groove. The must

be in the middle of the two backup rings.

27. Apply clean hydraulic oil or Parker Super O-Ring

Lube to the head of the plunger. Insert the plunger

into the counter bore in the piston, using a soft mal-

let if needed. Make sure the T-seals do not get

nicked or rolled.

Slide the spacer over the plunger with the large end

facing in. Install the snap ring into the groove.

28. Repeat Steps 23–27 for the other plunger.

Low-pressure cylinder

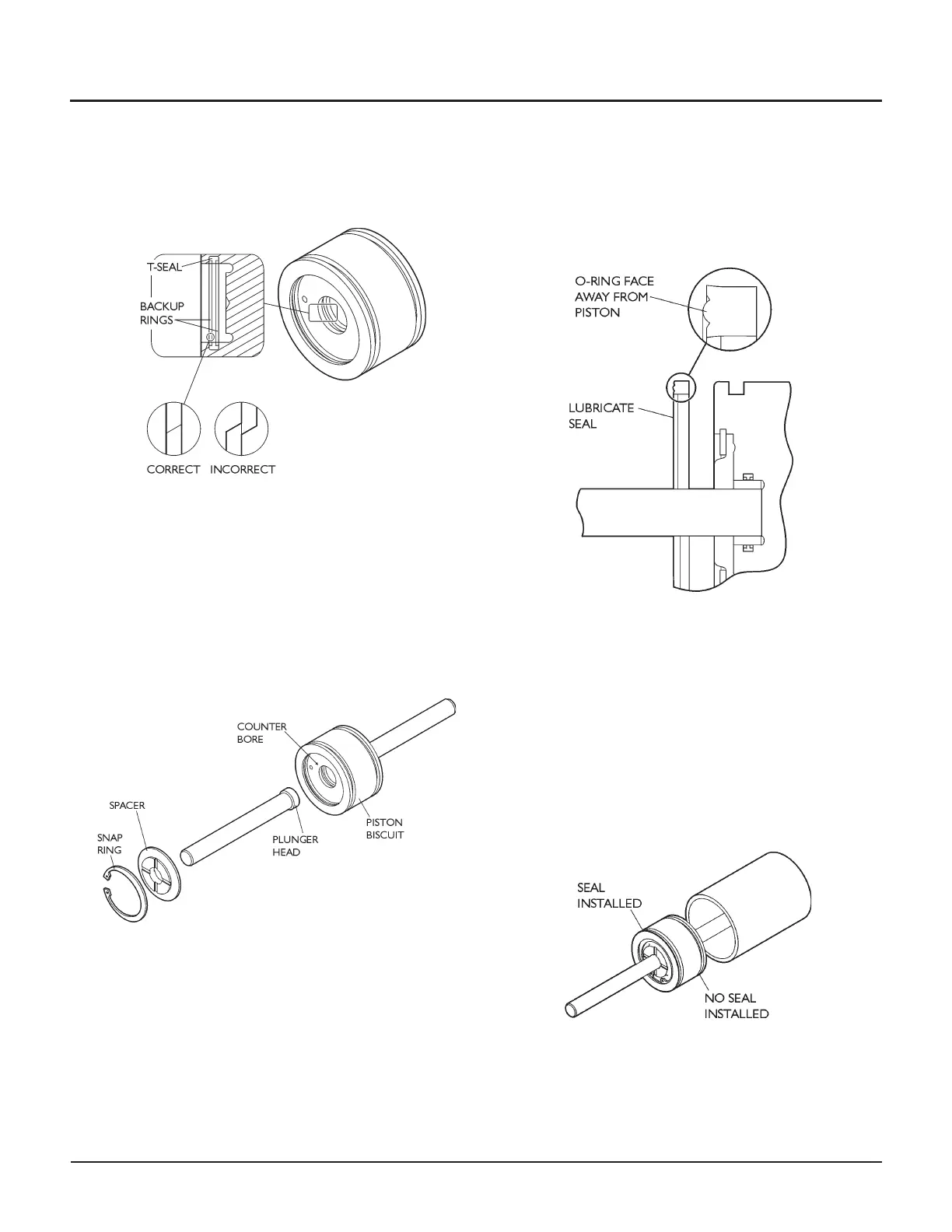

29. Apply clean hydraulic oil or Parker Super O-Ring

Lube to one new seal and the inside of the low-

pressure cylinder. Install the seal onto the piston with

the flared (o-ring) face toward the outside of the

piston.

30. Slide the piston and plunger assembly containing one

seal into the cylinder so that the empty groove enters

the cylinder first. Use a soft-faced mallet where nec-

essary.

CAUTION

Take care when the seal enters the cylinder.

It is compressed at this point and can easily

be damaged by rough handling.

© Flow International Corporation M-376 | 55

CHAPTER 3

Maintenance Procedures

Loading...

Loading...