31. Continue sliding the piston into the cylinder until the

empty seal groove on the piston exits the other end

of the cylinder.

CAUTION

If the seal starts to come out of the end of the cylinder,

do not force it back against the flare. Instead, push

the whole piston assembly through and start again,

this time stopping before the seal appears.

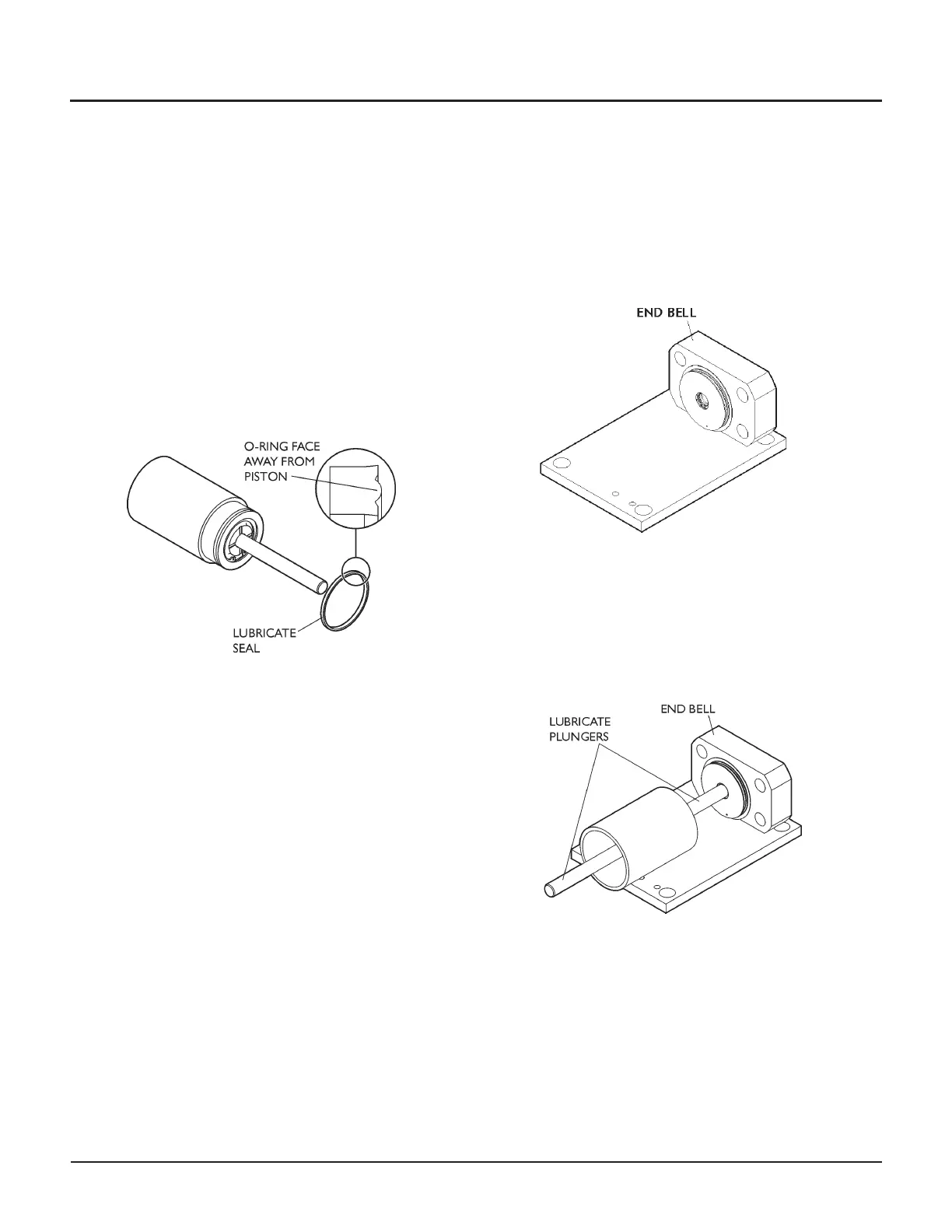

32. Apply clean hydraulic oil or Parker Super O-Ring to

the seal and install it in the groove on the piston,

making sure the flared o-ring face is toward the out

-

side of the piston.

33. Slide the piston and plunger back into the cylinder.

Take care when the seal is being compressed as it en

-

ters the cylinder—the seal can easily be damaged by

rough handling at this point.

Note: Centering the piston will make intensifier

re-assembly easier.

Set the cylinder containing the piston and plunger as

-

sembly aside.

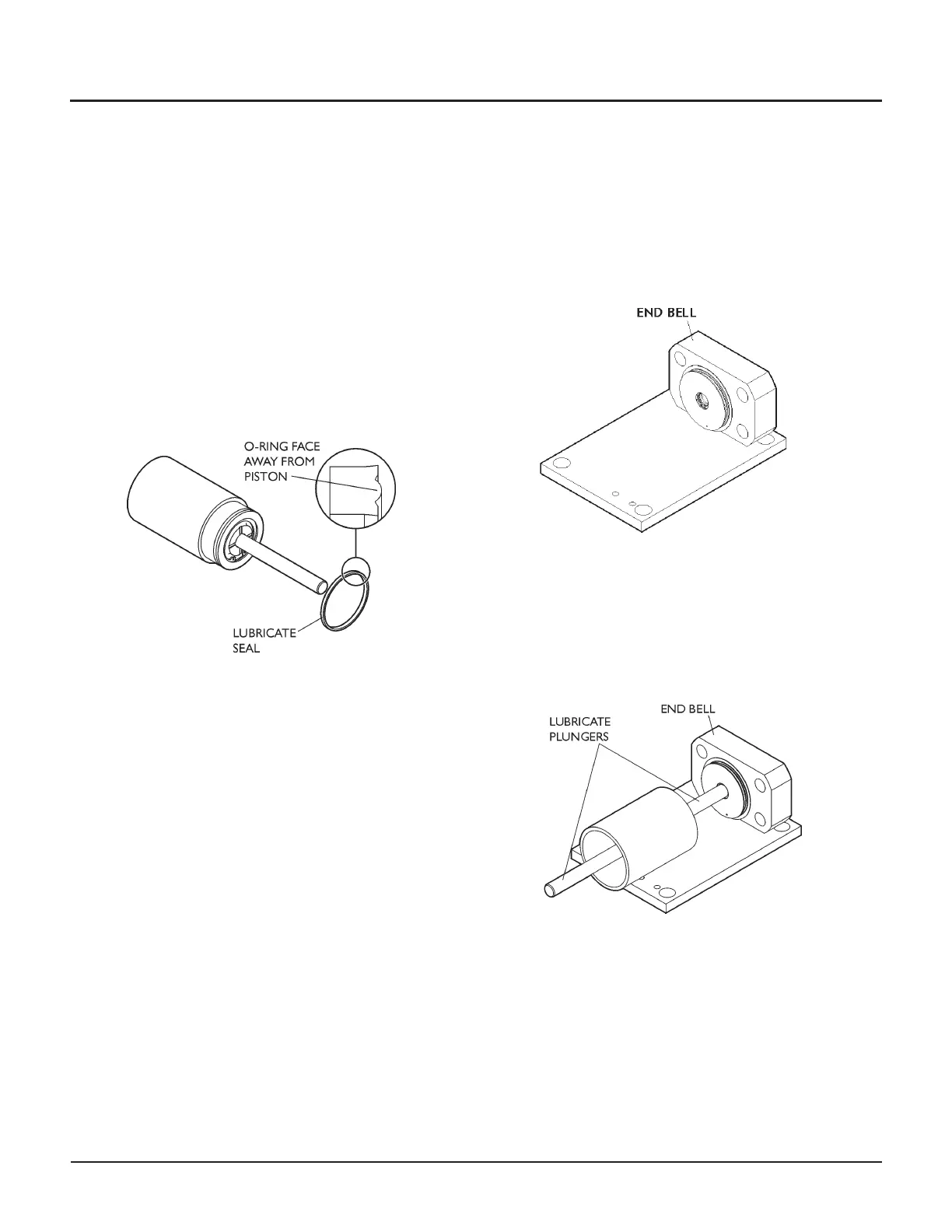

34. Mount an end bell to the assembly fixture. Insert the

fixture plate screw(s) and fasten finger tight.

Notes:

•

The short-block intensifier has one fixture plate

screw; the long-block intensifier has two

screws.

•

The backup ring and o-ring were lubricated

andinstalledinStep21.

35. Apply clean hydraulic oil or Parker Super O-Ring

Lube to both plungers. Install the cylinder by insert-

ing the plunger into the end bell.

36. Slide the remaining end bell over the other plunger

and seat it on the assembly fixture.

56 | M-376 © Flow International Corporation

94K HYPERPRESSURE INTENSIFIER

Loading...

Loading...