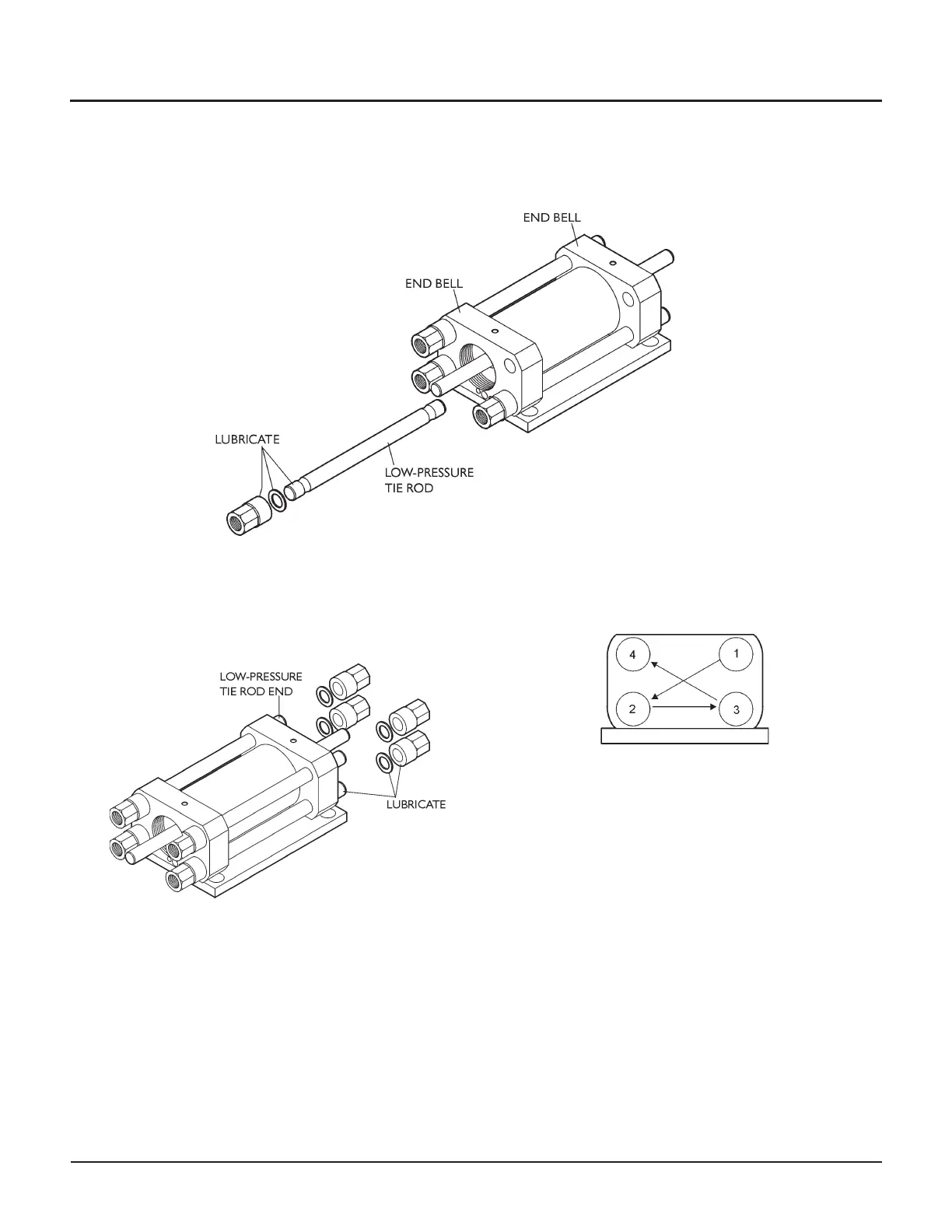

37. Thoroughly clean the tie rods to ensure no old anti-seize lubricant remains (it can interfere with proper torque up).

Then apply fresh anti-seize lubricant (A-10039) to one end of the low-pressure tie rods and to the faces of the

washers and nuts. Run the nuts onto the tie rods until they bottom out, then slide the tie rods through the two end

bells.

38. Apply anti-seize lubricant to the exposed threads of

the tie rods and the faces of the washers and nuts.

Install the nuts onto the tie rods hand tight.

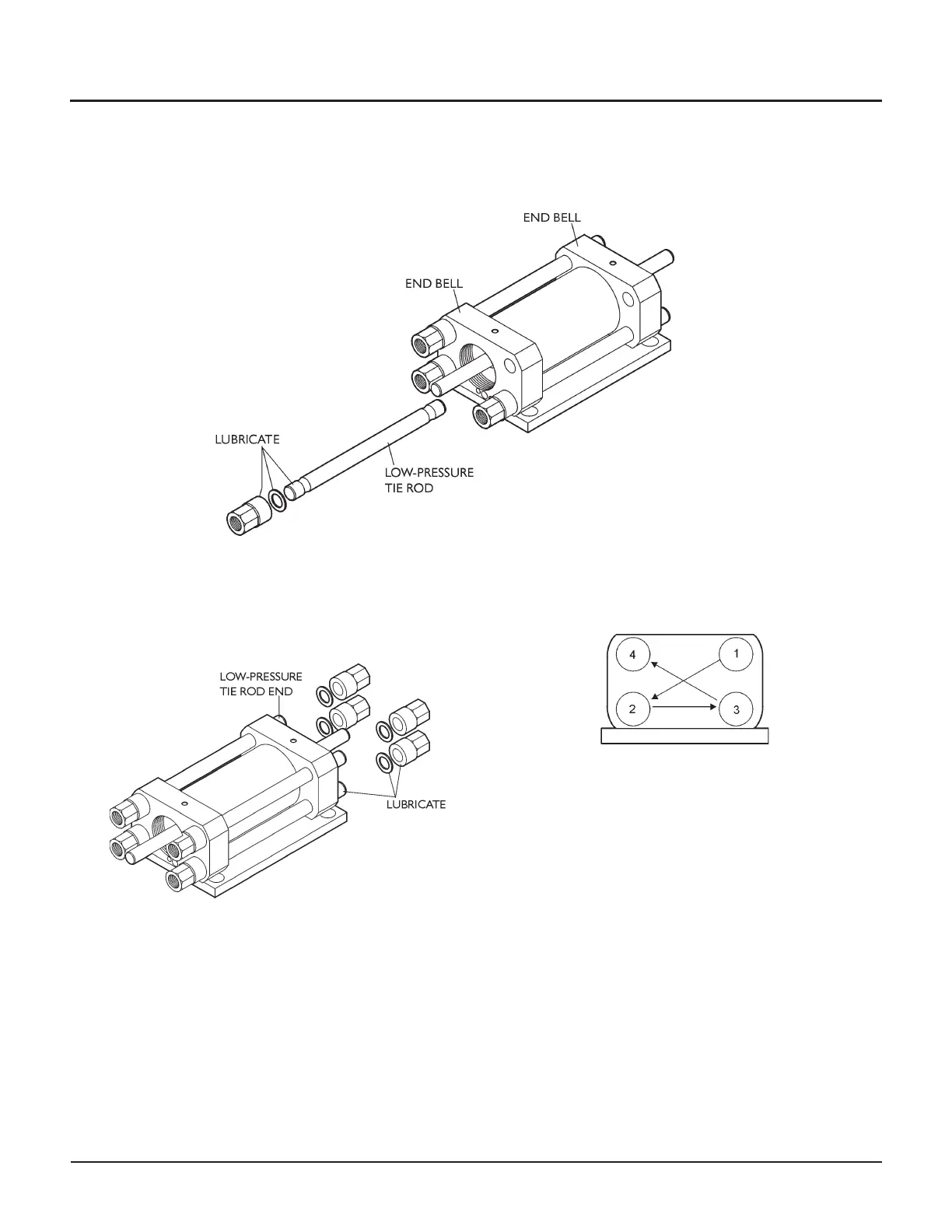

39. Draw the low-pressure cylinder carefully onto the

end bells by tightening the nuts evenly in a figure-8

pattern, as shown below. Be careful not to nick the

seals and back-up rings. There must be no seal or

back-up ring debris visible at the cylinder/end bell

interface. Be sure to check for any problems before

continuing.

Following the figure-8 pattern shown below, torque

all nuts evenly to 20 ft-lb (27 N-m) to seat all parts.

40. Loosen and remove nuts and washers from both

ends of the tie rods.

41. Visually center the tie rods between the end bells,

leaving the same number of tie rod threads exposed

on both sides of the assembly. Apply anti-seize lubri

-

cant to the faces of all mating components.

© Flow International Corporation M-376 | 57

CHAPTER 3

Maintenance Procedures

Loading...

Loading...